310 Stainless Steel

310 Stainless Steel is austenitic material used for high-temperature applications. The high chromium and nickel contents give the steel excellent oxidation resistance as well as high strength at high temperatures. This grade is also very ductile, and has good weldability enabling its widespread usage in many applications.

Grade 310S stainless steel is the low carbon version of Grade 310 and is suggested for applications where sensitization, and subsequent corrosion by high temperature gases or condensates during shutdown may become problem.

Grade 310 stainless steel is manufactured in accordance with ASTM A 167 and SX 310S to ASTM A 240.

310 Stainless Steel is austenitic material used for high-temperature applications. The high chromium and nickel contents give the steel excellent oxidation resistance as well as high strength at high temperatures. This grade is also very ductile, and has good weldability enabling its widespread usage in many applications.

Grade 310S stainless steel is the low carbon version of Grade 310 and is suggested for applications where sensitization, and subsequent corrosion by high temperature gases or condensates during shutdown may become problem.

Grade 310 stainless steel is manufactured in accordance with ASTM A 167 and SX 310S to ASTM A 240.

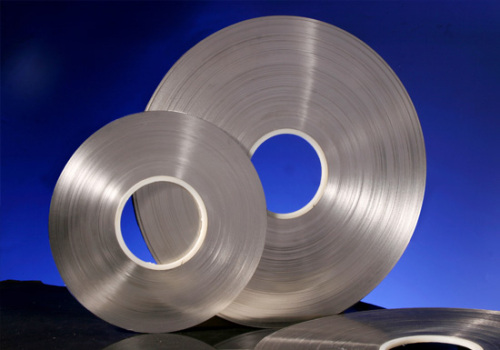

Sheet Thickness: 0.05mm and above

Typical ApplicationsGrade 310/310S find wide application in all high-temperature environments where scaling and corrosion resistance, as well as high temperature strength and good creep resistance, are required.

Chemical Composition

C | Mn | P | S | Si | Cr | Ni | |

310 | 0.25 max | 2.0 max | 0.045 max | 0.030 max | 1.5 max | 24.0 - 26.0 | 19.0 - 22.0 |

310S | 0.08 max | 2.0 max | 0.045 max | 0.030 max | 1.5 max | 24.0 - 26.0 | 19.0 - 22.0 |

Typical Properties (Annealed Condition)

1. Mechanical Properties at Room Temperature

1. Mechanical Properties at Room Temperature

Grade 310 | Grade 310S | |||

Typical | Minimum | Typical | Minimum | |

Tensile Strength, MPa | 625 | 515 | 575 | 515 |

Yield Stress (0.2 % offset), MPa | 350 | 205 | 290 | 205 |

Elongation (Percent in 50mm) | 50 | 40 | 50 | 40 |

Hardness (Brinell) | 172 | - | 156 | - |

Endurance (fatigue) limit, MPa | 260 | - | 260 | - |

2. Properties at Elevated Temperatures (ss310)

Short Time Elevated Temperature Tensile Strength

Temperature, oC | 550 | 650 | 750 | 850 | 950 | 1050 |

Tensile Strength, MPa | 550 | 430 | 280 | 180 | 90 | 50 |

Creep data

Stress to develop a creep rate of 1% in the indicated time at the indicated temperature.

Stress to develop a creep rate of 1% in the indicated time at the indicated temperature.

Time | TemperatureoC | 550 | 600 | 650 | 700 | 750 | 800 |

10 000 h | Stress MPa | 110 | 90 | 70 | 40 | 30 | 15 |

100 000 h | Stress MPa | 90 | 75 | 50 | 30 | 20 | 10 |

Creep Rupture Stress

Time | Temperature oC | 600 | 700 | 800 | 900 | 1000 |

1 000 h | Stress MPa | 190 | 110 | 50 | 35 | 15 |

10 000 h | Stress MPa | 170 | 70 | 35 | 20 | 10 |

100 000 h | Stress MPa | 110 | 55 | 25 | 10 | 2 |

Recommended Maximum Service Temperature (Oxidizing Conditions)

Continuous 1150oC

Intermittent 1035oC

Continuous 1150oC

Intermittent 1035oC