Brief introduction:

The KL series of lubricant distributor are a single main line, usually consisting of a piston pump lubricant into the main pipelines, and oil supply through the single-line to the oil filter in a one-to-one, one for each grease between greasing lubrication points are independent of each other. Oil filter is equipped with sensors, detecting each signal to grease to the grease, if not grease, will plug the output signal, it is usually affected by distance.

The KL lubricant distributor series are available for the position of grease consumption of different lubrication points, to grease frequently single centralized lubrication system, composed of double partition control lubrication of distribution system.

The KL series of lubricant distributor is the single line progressive distributor consists of carbon and alloyed structural steel manufacturing in the supply end of elements and 3~8 according to design needs to determine the amount of grease and the intermediate combinations of the number of ports.

The outlet ports of lubricant distributor are set on the two sides and also set in the above prepared to export, the intermediates are equipped with non-return valve in the outlet, can completely prevent resulting back pressure grease lubrication points upstream, ensure the grease outlet to quantitative, accurate.

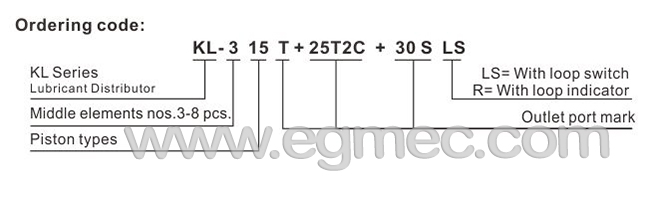

Ordering code:

Specification:

Model | KL | |||||||||||

Piston type | 25T | 25S | 50T | 50S | 75T | 75S | 100T | 100S | 125T | 125S | 150T | 150S |

Grease feeding ml/Cycle | 0.410 | 0.820 | 0.820 | 1.640 | 1.230 | 2.460 | 1.640 | 3.280 | 2.050 | 4.100 | 2.460 | 4.920 |

Outlet port | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 |

Max. pressure | 10Mpa to 21Mpa | |||||||||||

Medium: Penetration not lower than 265 (25°c, 150g) or 1/10MM grease viscosity grade than N120 oil: suitable for ambient temperatures of-10°c ~80°c.

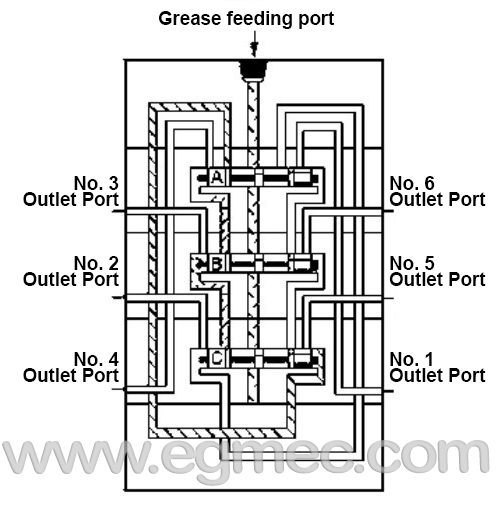

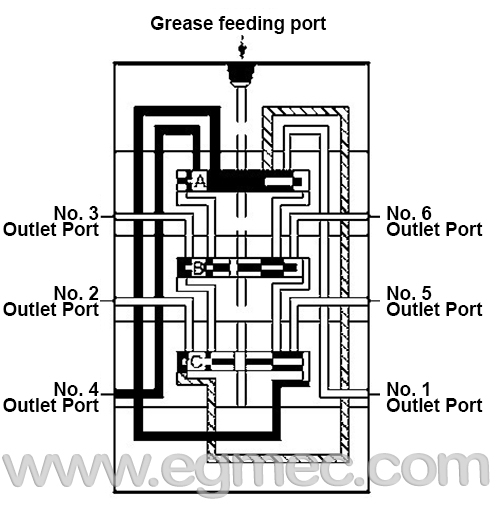

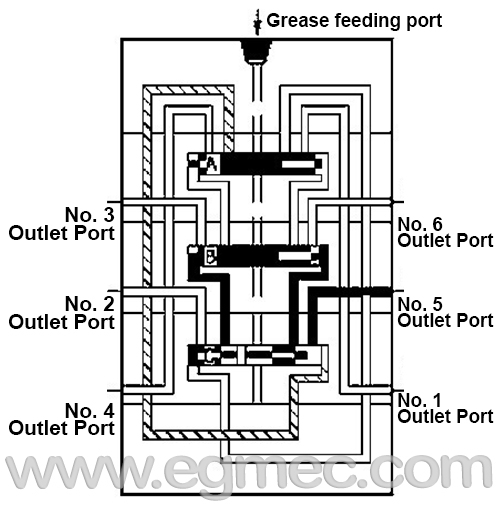

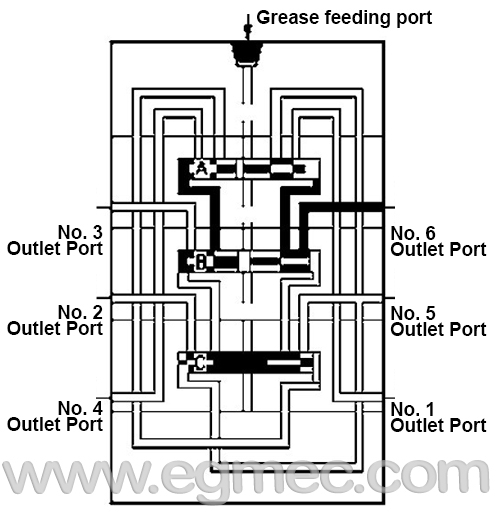

Operation description:

The grease squeezd by lubrication pump, supply flow press above photo shows the direction of the arrow drive piston A, B, C respectively.

Piston A, B left cavities in the effects of grease pressure in the right stationary, C into the lower right chamber pressures for piston, grease started moving to the left.

Lubricant grease flows promote the piston C left, lubricants exports to NO.1 in the cavities left by external piping to the lubrication point. The piston C movement to the left when the piston B cavity right was injected into lubricant grease.

Lubricant grease forwards the piston B to move to the left, lubricants exports to NO.2 in the cavities left by external piping to the lubrication point. As the piston B starts moving right to left when the pistons A cavity into the lubricant.

Lubricant grease forwards the piston A move to the left, the left cavity of the lubricant to the NO.3 export external piping to the lubrication point. As the piston A startS moving to the left when the piston C right cavity into the lubricant.

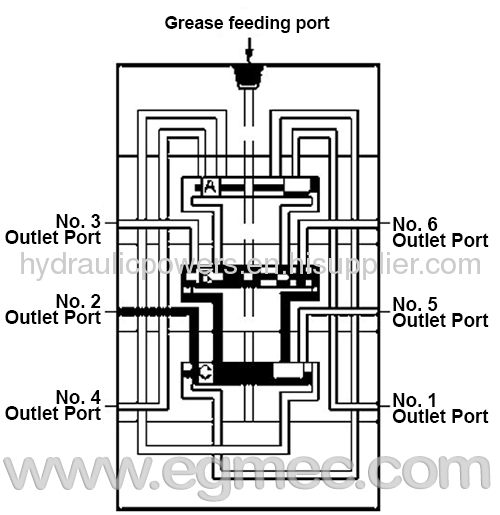

The inflow of the lubricant is to promote the piston C moves to the right, the right chamber of the lubricant pressure to the NO.4 discharge port via an external pipe to send to the lubrication points. The grease is pushed to enter the the piston B left chamber when the piston C moves to the right limit lubricant.

The inflow of the lubricant to promote position B rightward movement of the piston, the lubricant of the right chamber pressure to NO.5 outlet, external pipe fed to the lubrication points. When piston A piston B to move to the right limit the left chamber began to enter the lubricant.

The inflow of lubricant pushes piston A to the right chamber of the lubricant pressure to NO.6 outlet pipe , via the external is sent to the lubrication points. When the piston A moves to the return to the initial state, continue to repeat the action to the right limit.

The KL series of lubricant distributor

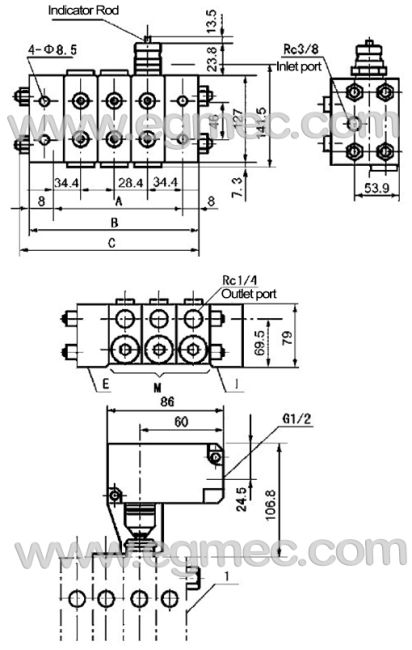

Lubricant Distributor Of KL Series Dimensions:

KL Series Dimensions Without Cycle Indicator And Switch

Model | Element numbers | A | B | C | Inlet thread | Outlet thread | Max. outlet ports | Weight (kg) | ||

L | M | E | ||||||||

KL-3 | 1 | 3 | 1 | 125.6 | 141.6 | 168 | Rc3/8 | Rc1/4 | 6 | 11.1 |

KL-4 | 1 | 4 | 1 | 154 | 170 | 196 | 8 | 13.3 | ||

KL-5 | 1 | 5 | 1 | 182.4 | 198.4 | 225 | 10 | 15.5 | ||

KL-6 | 1 | 6 | 1 | 210.8 | 226.8 | 253 | 12 | 17.7 | ||

KL-7 | 1 | 7 | 1 | 239.2 | 255.2 | 282 | 14 | 19.9 | ||

KL-8 | 1 | 8 | 1 | 267.6 | 283.6 | 310 | 16 | 22.1 | ||

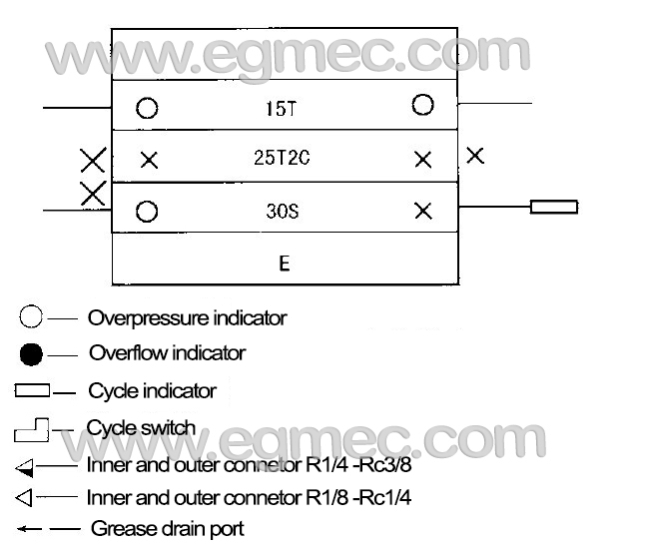

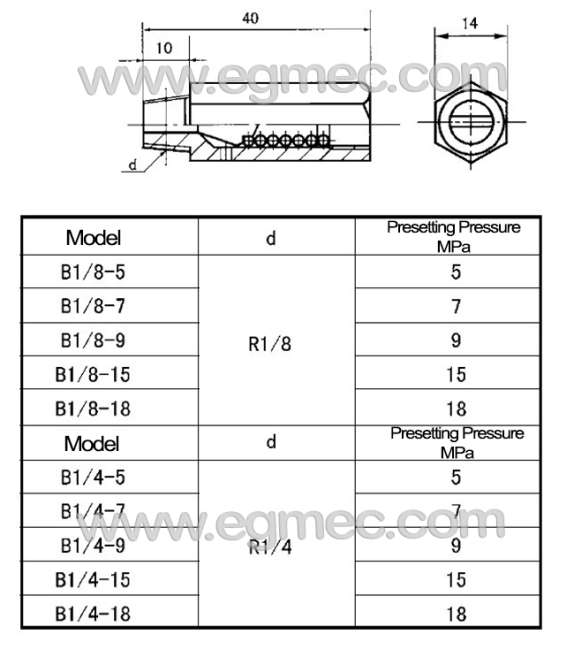

Indicator for overpressure:

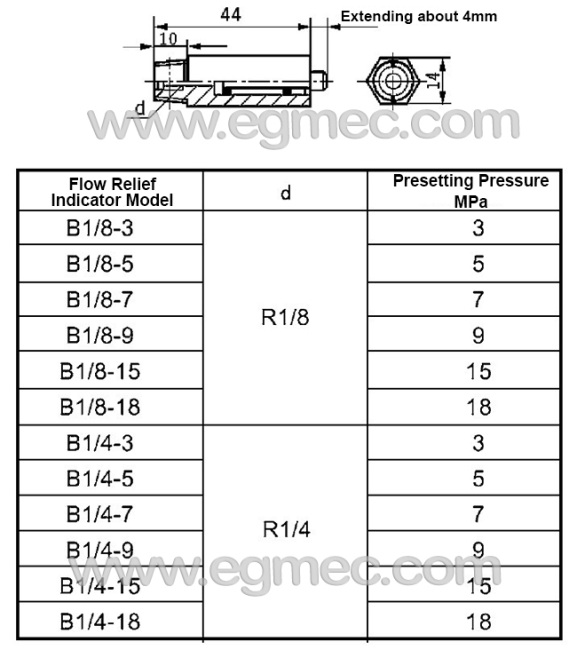

Flow relief Indicator :

The grease lubricant distributor of km series dimension of flow relief indicator is installed in the badly environment and easily blocked preparing outlet ports of each distributor, when the lubrication points or clogged , the pressure is abnormally elevated exceeds a predetermined value , the distributor is blocked point for grease spill out from the overflow outlet, by view of overflow point is the blocking point of failure as an examination.

Only apply to continuous operation position, no other distributor locations.

Outlet remark description:

T: As the basic standard, there are two grease outlet ports between the body sides.

S: Only one outlet port (T type, 2 outlet ports connected) , grease amount of the T-shaped twice, grease flows from left or right side.

LC: No left outlet port, view the right outlet port from the grease supply direction, and merge the grease with the adjacent rear element.

RC: No right outlet port, view the right outlet port from the grease supply direction, and merge the grease with the adjacent rear element

2C: No outlet ports, view the right outlet port from the grease supply direction, and merge the grease with the adjacent rear element.

How to Order Lubricant Distributor Of KL Series:

Please offer the code completely: KL-3(15T+25T2C+30S)R

Please provide the complete model number when ordering your subscription and provide the join map as follows: