Distributors needed for selling small injection molding machines

Districutors all around the are warmly welcomed to discussed partnerships with us on marketing our small plastic injection molding machines at their country, we commit provide competitive price and good plastic machine quality to you for marketing our machines smoothly at your market.

All parameters of our injection molding machine as below;

| Items | Parameter | Unit | Parameter Value (SSF250) | Parameter Value (SSF380) | Parameter Value (SSF500) | Parameter Value (SSF700) | Parameter Value (SSF900) | Parameter Value (SSF1180) | Parameter Value (SSF1480) | Parameter Value (SSF1680) | ||||||||||||

| Injection Unit | Screw diameter | mm | A | B | A | B | A | B | A | B | A | B | C | A | B | C | A | B | C | A | B | C |

| 22 | 25 | 27 | 30 | 28 | 30 | 34 | 36 | 32 | 35 | 38 | 35 | 38 | 42 | 38 | 42 | 45 | 42 | 45 | 50 | |||

| Screw L/D ratio | L/D | 17.7 | 15.5 | 18.4 | 16.5 | 19 | 17.7 | 18.8 | 17.7 | 24.8 | 22 | 20 | 22 | 20.2 | 18.4 | 22.1 | 20 | 18.6 | 23.6 | 22 | 19.8 | |

| shot volumn (theoretical) | Cm3 | 30 | 38 | 48 | 58 | 70 | 80 | 113 | 127 | 112 | 134 | 158 | 163 | 192 | 235 | 193 | 235 | 270 | 311 | 357 | 441 | |

| injection weight(PS) | g | 27 | 34 | 44 | 53 | 64 | 73 | 103 | 115 | 102 | 122 | 144 | 148 | 175 | 213 | 176 | 213 | 246 | 283 | 325 | 402 | |

| plasticizing capacity | g/s | 2.6 | 3.3 | 4.3 | 5.9 | 6.9 | 7.7 | 11.6 | 13 | 10.5 | 11.6 | 13 | 5.2 | 6.2 | 7.5 | 6.2 | 7.5 | 8.7 | 10 | 11.5 | 14.2 | |

| injection rate | g/s | 25 | 32 | 35 | 43 | 43 | 49 | 86 | 96 | 73 | 88 | 103 | 89 | 105 | 128 | 94 | 115 | 132 | 138 | 160 | 196 | |

| injection pressure | Mpa | 185 | 143 | 187 | 151 | 224 | 195 | 171 | 153 | 208 | 174 | 148 | 219 | 186 | 152 | 208 | 171 | 149 | 203 | 177 | 143 | |

| screw speed | rmp | 165 | 170 | 200 | 180 | 220 | 210 | 185 | 180 | |||||||||||||

| Clamping unit | clamp force | KN | 250 | 380 | 500 | 700 | 900 | 1180 | 1480 | 1680 | ||||||||||||

| open stroke | mm | 150 | 235 | 250 | 270 | 290 | 350 | 380 | 435 | |||||||||||||

| distance between tie bars (W*H) | mm | 240*190 | 240*240 | 290*270 | 315*300 | 360*320 | 370*370 | 410*410 | 460*460 | |||||||||||||

| max mould thickness | mm | 220 | 270 | 300 | 320 | 380 | 380 | 450 | 520 | |||||||||||||

| min mould thickness | mm | 80 | 80 | 100 | 150 | 150 | 150 | 160 | 180 | |||||||||||||

| ejector stroke | mm | 40 | 60 | 65 | 80 | 80 | 120 | 120 | 135 | |||||||||||||

| ejector force | KN | 13 | 17.5 | 20 | 27 | 31 | 38 | 50 | 50 | |||||||||||||

| ejector number | PC | 1 | 1 | 1 | 1 | 5 | 5 | 5 | 5 | |||||||||||||

| dia of mould location hole | mm | 55 | 80 | 100 | 100 | 125 | 125 | 125 | 125 | |||||||||||||

| Others | max pump pressure | Mpa | 14 | 14 | 16 | 16 | 16 | 16 | 16 | 16 | ||||||||||||

| pump motor power | KW | 3 | 4 | 5.5 | 7.5 | 9 | 13 | 13 | 18.5 | |||||||||||||

| heating power | KW | 2.5 | 3.2 | 3.9 | 5.1 | 6 | 7.3 | 9.3 | 12.3 | |||||||||||||

| machine dimension | m | 2.75*0.86*1.35 | 2.9*1.0*1.4 | 3.2*1.1*1.6 | 3.6*1.2*1.65 | 4*1.27*1.75 | 4.3*1.28*1.9 | 4.5*1.35*1.9 | 5.13*1.45*2.12 | |||||||||||||

| machine weight | T | 1 | 1.35 | 1.9 | 2.2 | 2.9 | 3.4 | 4 | 6 | |||||||||||||

| oil tank capacity | L | 85 | 90 | 115 | 130 | 150 | 230 | 250 | 300 | |||||||||||||

Standard features of the injection molding machines;

1.Double-cylinder balanced injection system;

2.Multi-stage pressure &speed injection;

3.Back pressure adjustment device;

4.Low pressure mold protection;

5.Single hydraulic core pulling and inserting;

6.Multiple hydraulic ejector knock-out;

7.Mechanical, electrical safety device;

8.Auto lubrication system;

9.Hydraulic pressure full proportional control;

10.Computer control system;

11.Molding data memory system;

12.Automatic mould adjust function.

13.T-slot mold plate;

14.Energy saving with variable pump;

15.Bi-metallic screw to anti-corrosion, which is applicable to nylon or glass material.

16.Five-point inward moving toggle system ensure high rigidty and precision for mold clamping and also reducing stress and stain effects;

17.Oil pipelines are positioned for aesthetic appearance and easy for maintenance;

18.The moving platen is fitted with adjustable slide support system to improve platen parallelism and provide better tie bar and mould protection and lengthen the working lifetime;

19.Nozzle alignment is provided using a simple mechanism with fine adjustment for accurate centering.

Warranty of SS brand injection molding machine;

Machines that used within 12 months(Based on the date machine leaves our company) will be warranted as below;

1.Warranty of mechanical components(except screw and barrel) is 12 months;

2.Warranty of electrical appliances and hydraulic units(except heating ring) is 6 months;

3.Warranty of screw, barrel and heating ring is 3 months;

4. Above warranty is not applicable for the errors that due imporper operation.

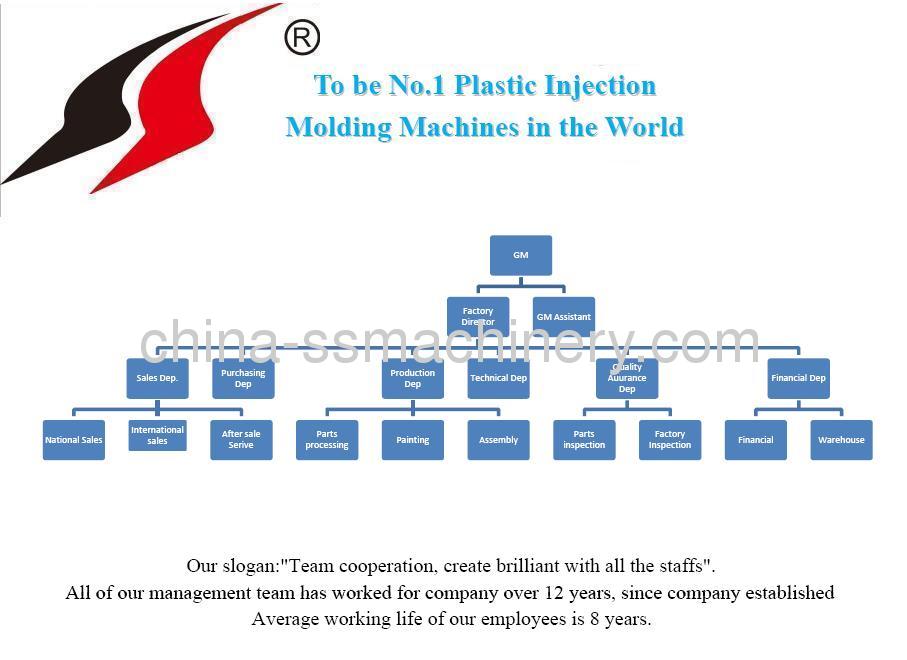

Organization chart;

Quality certificate;