Note:

A. Suffix Xn denotes fiber tyoe

B. The colour arrangements of fiber and tube are specified in the colour identification cable

C. The nominal value of the PE sheath minimum thickness outside of the strength member is 0.8mm

D. The steel tape is not corrugated in the cable with 12 fibers below. If the corrugated steel tape is requested ,it should be specified in contract

-----------------------------------------------------------------------------------

Discription

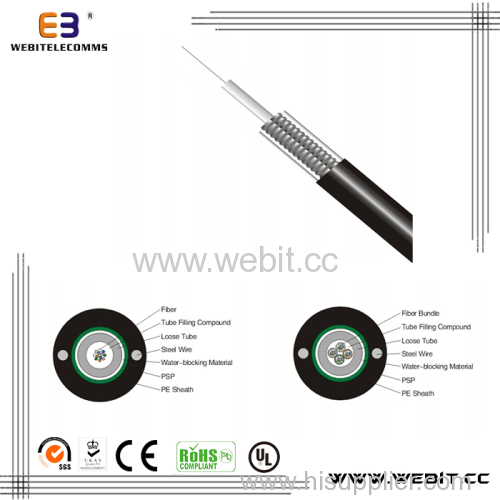

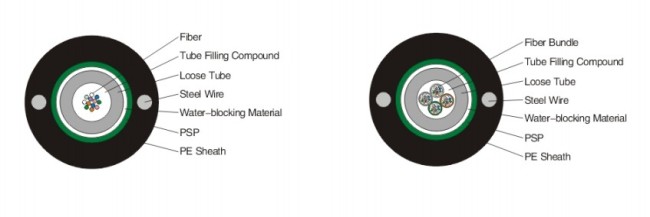

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic . The tubes are filled with a water-resistant filling compound. A steel wire,sometimes sheathed with polyethylene(PE) for cable with high fiber count,locates in the center of core as a metallic strength member.

Tubes(and fillers)are stranded around the strength member into a compact and circular cable core. The PSP is longitudinally applied over the cable core. which is filled with the filling compound to protect it from water ingress. The cable is completed with a PE sheath

------------------------------------------------------------------------------------

Features:

* Good mechanical and temperature performance

* High strength loose tube that is hydrolysis resistant

* special tube filling compound ensure a critical protection of fiber

* Crush resistance and flexiblity

* PSP enhancing moisture-proof

* Two parallet steel wires ensure tensile strength

* Small diameter ,light weight and friendly installation

* Long delivery length

-------------------------------------------------------------------------------------

Standards:

Comply with YS/T901-2009 as well as IEC 60794-1