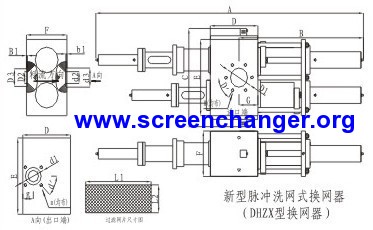

screen changer with self -cleaning system

screen changer for plastic recycling equipment

screen changer for high yield device

High savings on screen costs, extremely short cleaning cycles at low melt loss and flushing the durable screens over the entire surface area are arguments clearly in favour of DEAO's fully automatic backflush system. The patented backflush system uses the short, clearance-free flow channels of the melt during filtering and also during the backflushing. Your benefit: Intelligent concepts reduce pressure and melt losses to a minimum, and increase screen service life and production reliability.

The Back-flush screen changer from our company is similar with the double piston screen changer,and it adds a back-flush cylinder which is connected with the double piston. screen washing on line available(A small amount of clean material flows in reverse under high pressure, rinse the dirty screen, we called this process self-cleaning .

Advantages:

1, no need to stop the on-going machine

2, no need to replace the screen, one screen can be used more than 100 times

3, no need manual operation when screen changing.

Advantages:

1, no need to stop the on-going machine

2, no need to replace the screen, one screen can be used more than 100 times

3, no need manual operation when screen changing.

.sheet

.coating

.pipe

.compounding

.wire and cable

.tubing

.lab lines

.textiles (fiber and nonwovens)

.EVA. hot melt adhesive and PSA

.Pelletizing(strands and under water)

.Recycling of most polymers

.Blown film and cast film

.FPVC. Corrosive and degradable materials

Technical data

Type | Screen size L×W (cm) | Screen area(cm2) | Pressure (Mpa) | Heating Power(kw) | Output(kg/h) |

DHZX-120 | 193×2 | ≤25 | 14 | ≤2000 | |

DHZX-160 | 423×2 | ≤25 | 14 | ≤2500 | |

DHZX-1800 | 47×19 | 900×2 | ≤25 | 14 | ≤3000 |

DHZX-2000 | 47×21 | 1000×2 | ≤25 | 14 | ≤4000 |

DHZX-2250 | 53×21 | 1125×2 | ≤25 | 14 | ≤4500 |

DHZX-2700 | 53×25 | 1335×2 | ≤25 | 14 | ≤5400 |

DHZX-3300 | 66×25 | 1650×2 | ≤20 | 20 | ≤6600 |

DHZX-4400 | 88×25 | 2200×2 | ≤20 | 20 | ≤8400 |

DHZX-5650 | 94×30 | 2827×2 | ≤20 | 20 | ≤11300 |

patent owned

The application cases