30CrMo Forged Pipe Mould

Specification:

1.making ductile iron pipes DN50-DN1200

2. material:21CrMo10/35CrMo to DIN17350

3. for longtime use

4. pipe mold

Production range: DN75MM-DN1200MM

The material of pipe molds is 21CrMo10 and30CrMo to DIN17350, and size DN50-DN1200.they are used for producing ducitleiron pipes basd on centrifugal machines.

The main technical specification of the pipemoulds are as per follows:

Material

21CrMo10 and 35CrMo to DIN17350

2. Chemical Components

21CrMo10

Components | C | Mn | Si | P | S | Cr | Mo | Cu |

0.16 0.23 | 0.20 0.40 | 0.20 0.40 | ≤ 0.011 | ≤ 0.009 | 2.20 2.60 | 0.30 0.50 | ≤ 0.20 |

35CrMo

Components | C | Mn | Si | P | S | Cr | Mo | |

0.32 0.40 | 0.40 0.70 | 0.17 0.37 | ≤ 0.025 | ≤ 0.015 | 0.80 1.10 | 0.15 0.25 |

3.smelting method

electric arc furnace + refining furnace(vacuum arc degassing)

4. Technical parameters of machining

Spec. (ID mm) | Length m | surface roughness | Precision mm | Concentricity mm | Conicity mm | |

100~1200 | 6.5 | 1.6 | 0.1 | 0.08 | 0~1 | |

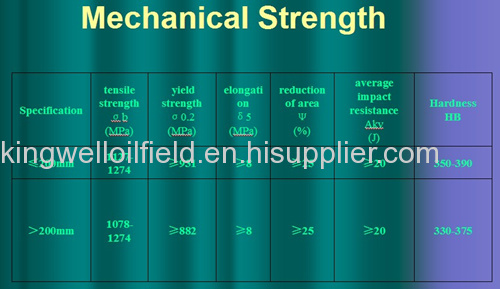

5. Mechanical properties(according to DIN17350, DIN 21CrMo10)

σb | σs | σ5 | Ψ | Hardness |

750~850N/mm2 | ≥650N/mm2 | ≥16% | ≥60% | 225 — 265HB |

6. Test method and standard

Test spots: half spot of wall thickness,two portraits of such spot.

Tensile test: GB/T288-2002 standard.

Hardness test: GB/T231 standard.

7. The standard of ultrasonic test

The forging of the mould will be ultrasonically tested as per JB/T1581-1996 or equivalent standard, details as follows:

a. Without bursts, crack, shrinking hole and other defects.

b. The defect with size within 2mm can be ignored.

c. There should not have compact district.

d. Individual defect with diameter of 2~4mm is permitted, and the distance of the neighboring defects should be more than the 10 times of the bigger one's. For 100cm2' s area, the quantities of the defects with diameter of 2~4mm should not exceed 3.

The above-mentioned parameters are for reference only,we can produce various kinds of pipe mold as per customers' requirements.

About us:

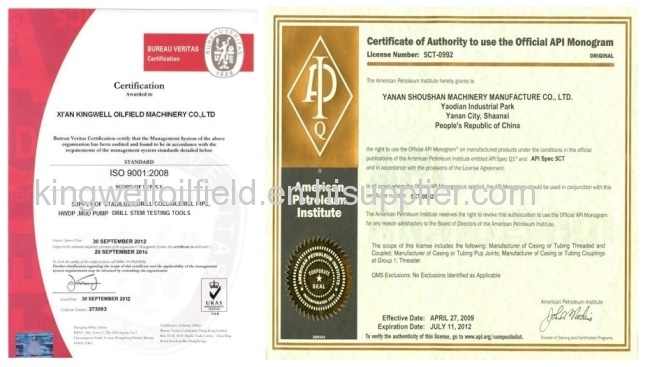

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service supplier to a manufacture who have own factory and specially produce stabilizer, forgings, BOP & spare parts and DST tools products.

We have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. We can provide highly efficient services to each client resulting in accurate and timely deliveries at the best prices. We sincerely hope to make cooperation and mutual benefit wih any people who are in Oil & Gas industry.

Welcome any of your enquiry, we will try to show you our best price and most timely service.