Specifications

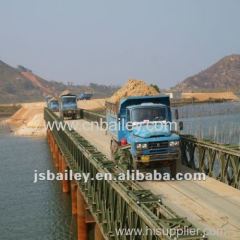

1 Bailey Type bridge

2 Portable pre-fabricated truss bridge

3 Fast Install

4 Send engineers to provide a technology guidance

Bailey Bridge requires no special tools or heavy equipment for construction, the bridge elements are small enough to be carried in , and the bridge is strong enough to carry . It is considered a great example of military engineering.

Bailey Bridge requires no special tools or heavy equipment for construction, the bridge elements are small enough to be carried in , and the bridge is strong enough to carry . It is considered a great example of military engineering.

The compact 200 panel bridge: The compact 200 panel bridge is similar to the compact 100 panel bridge from their appearance. The difference is its increased panel height to 2.134m. It employed the method of alternating joints between Reinforcement Chords and the joints between panels. This method can decrease inelastic deformation caused by the oversized pinholes. Pre-arch method is used to additionally cut down mid-span and vertical deflection to a larger degree. Bolt-connected components use the orienting sleeve- fixing method to increase accuracy of connections. Shear is created in orienting sleeves and tension is developed in bolts, which increase the usage life of the bolts and ensure the safety of panel bridges. Wind resistant brace is made to be composite type and is connected to transom/girders to improve overall stability of panel bridges.

The part between braced frame and panels is fixed through bridging so as to prevent the whole bridge from side bending. After the erection, there will be a pre-arched degree over the span of the bridge. Besides it can be assembled into single-lane bridges. The compact 200 panel bridge can also be assembled into double lane bridge, hence it broadens its application range. It is suitable for the load designs of HS-15, HS-20, HS-25 and pedrail-50 etc.