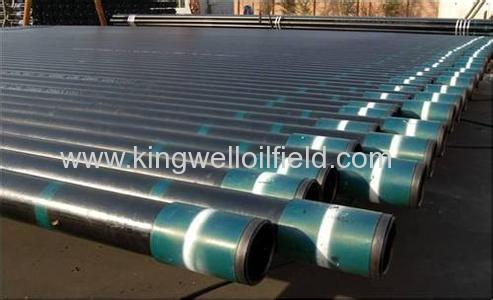

Drill Pipe Introduction:

Product features

Our drill pipe are manufactured in according to or exceeds the requirement of API 5DP. The features are introduced as below:

1. The residual elements such as sulphur and phosphorus are strictly controlled in the pipe body and tool joints material during the steel making process, which makes the kind of material with high physical properties.

2. Heat Treatment is a decisive process in the production of tool joints and pipe body. Heat treatment must be uniform and deep enough to ensure required physical properties full length, especially in the critical sections of the connection and weld zone. Heat treatment programs are established on the basis of the actual chemical analysis of each heat of steel to ensure the materials meet or surpass the requirements of API Specification.

3. The drill pipe undergo a full-length inspection that checks the defects; especially the strict inspections on weldneck/upset region are preformed with our both manual and automatic inspection equipments to ensure the high quality.

4 The thread is the most important factor for drill pipes. All threads would be machined with CNC Lathes and inspected with related thread gauges in conformance with API Specification. All threads would be phosphated or copperized and the roots are cold rolled to improve the resistance of galling during initial break-in and drilling operation. Upon the customer's request, The Break-in process is conduced to economize the rig handling time. All Connections would be equipped with pressed steel or plastics steel thread protectors.

Material

KINGWELL provides a full range of inertial friction welding drill pipes in nominal sizes from 2-3/8" to 6-5/8" OD and various steel grades (E-75, X-95, G-105, S-135), which are manufactured in according to API 5DP Latest Edition and meeting the customer's specified requirements.

1,Drill Pipe Body

KINGWELL drill pipe performs a strict quality control on manufacturing and inspection process from the initial material selection to final inspection to meet the requirement of the customer. The drill pipe is manufactured with top-quality alloy steel, which SYBH will perform the strict mechanical and chemical re-inspection. The advanced inspection system can precisely detect the defects and check the dimensional tolerance to ensure API required 87.5 minimum percent wall thickness, and even provide 95 percent minimum wall thickness in every pipe.

2,Tool Joints

KINGWELL tool joints are made of AISI 4137H premium alloy steel fully Q&T with IPSEN furnace imported from Japan. All tool joints should be inspected by fluorescence magnetic particle and ultrasonic method.

The threads and Bevel shoulders are machined by CNC Lathe and gauged to API specification, which provides interchangeability between various types of connections. All threads are phosphatized or coppered to reduce the possibility of connection galling.

Standard | Steel grade | Yield strength Min/Max(ksi) | Tensile strength Min (ksi) | Hardness | Min. Avg

Charpy |

API | E—75 | 75/105 | 100/- | - | 40 |

X—95 | 95/125 | 105/- | - | 40 | |

G—105 | 105/135 | 110/- | - | 40 | |

S—135 | 135/165 | 145/- | - | 40 | |

Tool Joint | 120/- | 140/- | 341HB | 40 |