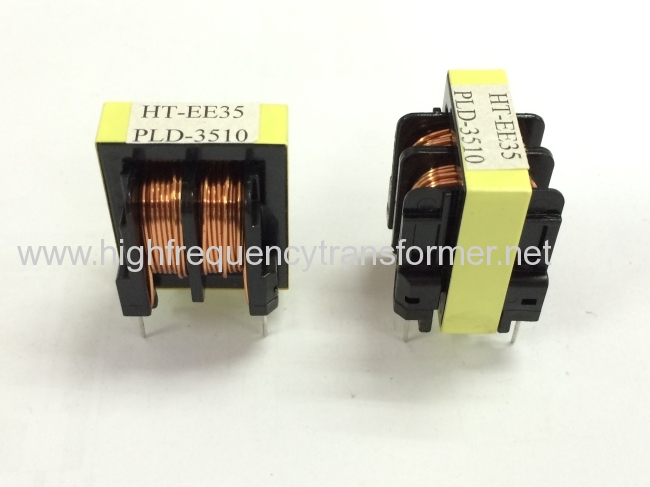

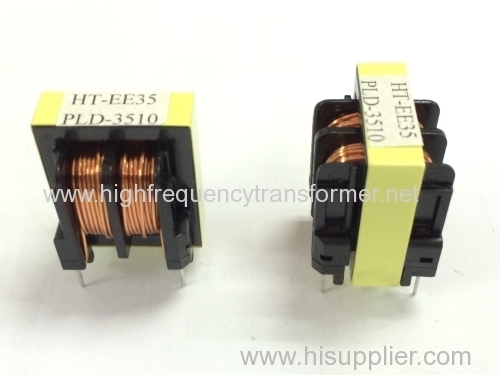

EE35 type high frequency transformer

Specifications

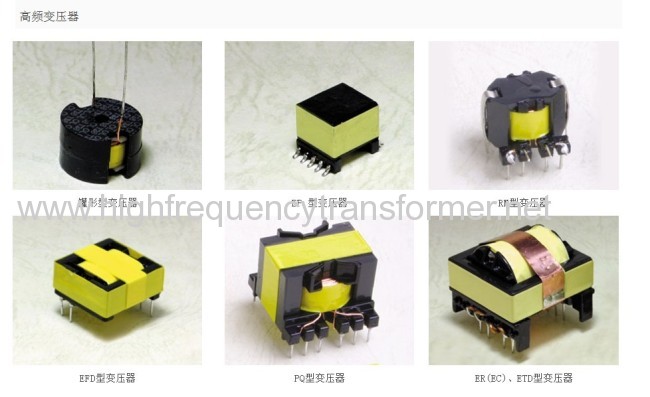

high frequency EE35 transformer:

1. small order is accepted.

2. appreciate your own specification.

Applications:

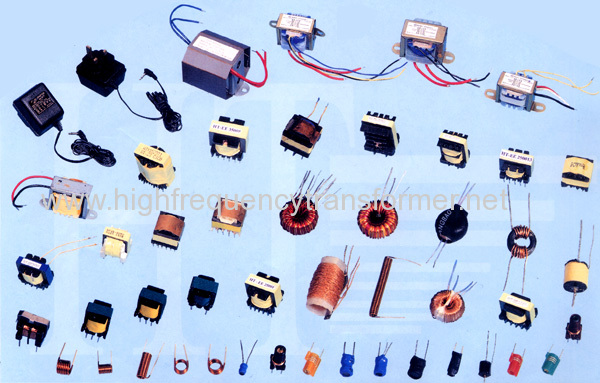

VCRS, Copy machine , Audio equipment , Game machines

TV sets, Microcomputer equipment

communications control equipment

printers, Terminals

good magnetic shield form itself and slight interference

Gold supplier authenticated by Hisupplier.

Safe and easy to buy from us.

Trade Term:

Payment: 30% deposit By T/T, Western Union, Paypal, 70% before delivery.

Production Lead time: 7~25days;

Shipping methods: You can choose EMS/DHL/UPS/Fedex/TNT/standard airfreight or ocean freight via international forwarder according to gross weight & Volume. In order not to increase the risk of losing goods and shipping time,

FOB Shipping port: HongKong or Shenzhen

If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

Enquiry: contact us by email, phone call, fax, Instant tools (Trademanager, MSN, Skype) and let us know your enquiry.

Discussion: specify the items you desire, confirm specification; OEM/ODM consultation.

Quotation: Prices offered and accepted.

Place order as per contract or discussion.

Proforma invoice offered to double confirm the order for both-side records.

Payment settled.

Order completed under our arrangement.

Goods shipped as per contracted term.

Goods arrive at local port or warehouse, depending on contracted term.

Support & re-ordering.

Application:Transformers are also used extensively in electronic products to step-down the supply voltage to a level suitable for the low voltage circuits they contain. The transformer also electrically isolates the end user from contact with the supply voltage.

Transformer introduction:A transformer is a static electrical device that transfers energy byinductive coupling between its winding circuits. A varying current in theprimary winding creates a varying magnetic flux in the transformer's coreand thus a varying magnetic flux through the secondary winding. This varying magnetic flux induces a varying electromotive force (emf) orvoltage in the secondary winding. Transformers can be used to vary the relative voltage of circuits or isolate them, or both.

Transformers range in size from thumbnail-sized used in microphones to units weighing hundreds of tons interconnecting the power grid. A wide range of transformer designs are used in electronic and electric power applications. Transformers are essential for the transmission,distribution, and utilization of electrical energy.

Effect of frequency

Transformer universal emf equation

If the flux in the core is purelysinusoidal, the relationship for either winding between its rms voltage Erms of the winding, and the supply frequency f, number of turns N, core cross-sectional area a in m2 and peak magnetic flux densityBpeak in Wb/m2 or T (tesla) is given by the universal emf equation:[15]

If the flux does not contain evenharmonics the following equation can be used for half-cycle average voltageEavg of any waveshape:

The time-derivative term in Faraday's Law shows that the flux in the core is the integral with respect to time of the applied voltage.[25] Hypothetically an ideal transformer would work with direct-current excitation, with the core flux increasing linearly with time.[26] In practice, the flux rises to the point where magnetic saturation of the core occurs, causing a large increase in the magnetizing current and overheating the transformer. All practical transformers must therefore operate with alternating (or pulsed direct) current.[26]

The emf of a transformer at a given flux density increases with frequency.[15] By operating at higher frequencies, transformers can be physically more compact because a given core is able to transfer more power without reaching saturation and fewer turns are needed to achieve the same impedance. However, properties such as core loss and conductor skin effect also increase with frequency. Aircraft and military equipment employ 400 Hz power supplies which reduce core and winding weight.[27] Conversely, frequencies used for some railway electrification systems were much lower (e.g. 16.7 Hz and 25 Hz) than normal utility frequencies (50 – 60 Hz) for historical reasons concerned mainly with the limitations of early electric traction motors. As such, the transformers used to step-down the high over-head line voltages (e.g. 15 kV) were much heavier for the same power rating than those designed only for the higher frequencies.

Power transformer over-excitation condition caused by decreased frequency; flux (green), iron core's magnetic characteristics (red) and magnetizing current (blue).

Operation of a transformer at its designed voltage but at a higher frequency than intended will lead to reduced magnetizing current. At a lower frequency, the magnetizing current will increase. Operation of a transformer at other than its design frequency may require assessment of voltages, losses, and cooling to establish if safe operation is practical. For example, transformers may need to be equipped with 'volts per hertz' over-excitation relays to protect the transformer from overvoltage at higher than rated frequency.

One example of state-of-the-art design is traction transformers used for electric multiple unit and high speed train service operating across the,country border and using different electrical standards, such transformers' being restricted to be positioned below the passenger compartment. The power supply to, and converter equipment being supply by, such traction transformers have to accommodate different input frequencies and voltage (ranging from as high as 50 Hz down to 16.7 Hz and rated up to 25 kV) while being suitable for multiple AC asynchronous motor and DC converters & motors with varying harmonics mitigation filtering requirements.

Large power transformers are vulnerable to insulation failure due to transient voltages with high-frequency components, such as caused in switching or by lightning.

Why Choose us,

Shipping ways:DHL,UPS,EMS,FedEx

Please send us following information for quote via Email.

Bobbin dimension, core materials, winding drawing and other requirements.

Main Buying Procedures:

package:

Product: