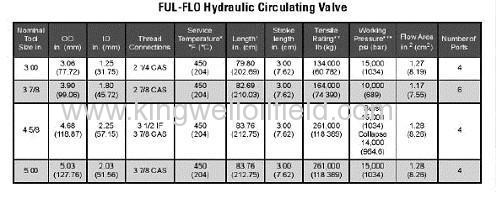

DST Tools 5" Ful-Flo Hydraulic Circulating Valve

Size: 5", 3 7/8", 4 5/8"

Product mode:Ful-Flo Hydraulic Circulating Valve

Working pressure:10000psi ~ 15000psi

Brand Name:Kingwell

Certification: API, ISO

Usage: drill stem testing

Working condition: High pressure high temperature(HPHT)

Briefly Introduce

The FUL-FLO hydraulic circulating valve serves as a bypass around the packer or as a circulating valve to circulate a well after testing.

When run below a closed valve, the tool serves as a bypass around the packer and helps relieve pressure buildup below the closed valve when it is stung into a production packer.

When run above a closed valve, the tool can be used as a circulating valve when the workstring is picked up.

Features and Benefits

• Permits passage of wireline tools through its full-opening bore

• Requires no pipe rotation to operate

Operation

Bypass ports close when weight is set down and reopen when weight is lifted.

A hydraulic metering system provides a 2 to 3-minute delay in closing after weight is applied. This delay allows either the RTTS packer to be set or the test string to be stung into a permanent packer before the bypass ports close. The ports reopen without a time delay.

During stimulation work, the latching piston adds a downward force on the circulating sleeve to help keep the valve closed.

Operation of the valve is the same whether it is used as a circulating valve or as a bypass. No torque is required. Weight is applied to close the tool, and the workstring is picked up to reopen it.

Specifications:

1. Halliburton type, all could change with Halliburton parts.

2. All equipments are produced according to API standard NACE MRO175-2002

Below are spec for you reference:

Inspection and Test Facilities

We own the world-class facilities with professional laboratory technicians. The main facilities are Surface Testing (Hydraulic Testing Unit), high temperature heat treatment furnaces, API Gages (Master & Working), Profile Projector, tensile testing machine, pressure sensor and data acquisition system, Universal Testing Machine, Hardness Tester, Nitrogen Pump, Function Test Pump, Ultrasonic Thickness Tester etc. All the goods must be tested by several processes and must be qualified when packed.

The followings are some pictures of Test Facility

Training and Field Supports

We have a team of well qualified and experienced field support personnel for Training. According to customer's requirements, we provide operation training service for our customers who purchase our products.

Generally speaking, our customer training mainly includes followings:

1) To know the basic knowledge of the products, such as the usage, the working environments, the working principles, the structure, ect.

2) To learn the operation and use of products.

3) To master the basic requirement of designs of tool strings and of testing operation.

Service

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement

Company introduction

XI'AN KINGWELL OILFIELD MACHINERY Co., Ltd. (KINGWELL) is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provides complete solutions.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce OCTG, DST tools and Solid control products.

KINGWELL have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. kingwell can provide highly efficient services to its clients resulting in accurate and timely deliveries at the best prices. Our products have been exported to Europe, American and Middle East.