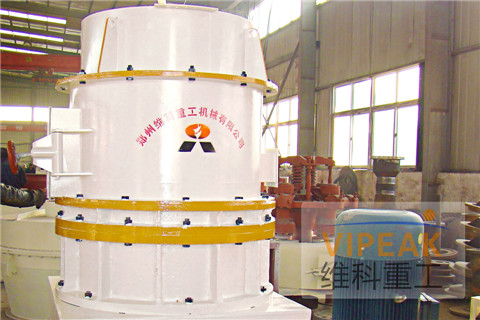

Straight Centrifugal Grinder

Raw Materials: carborundum, zirconite, quartz, granite, barite, marble, limestone, talc, gypsum, slag, porcelain, etc.

Application: Silica sand, foundry sand, grinding apparatus and abrasive sand and other fine sand industry

Straight Centrifugal Grinder is a new and efficient milling equipment to replace Raymond mill, Ball mill, and other traditional mill equipments.

MGZ series Straight Centrifugal Coarse Powder Grinder is designed by Vipeak grinding mill engineer, it's a new type advanced grinding machine based on clients' requirements domestic and overseas and it concentrate research experience in grinding mill industry, to replace traditional Raymond mill and ball mills which only processes fine powder. Straight Centrifugal Coarse Powder Grinder is widely applied in silica sand, foundry sand, grinding apparatus and abrasive sand and other fine sand industry, it can match up with fine powder machine to make closed-circuit production line to produce product in different sizes, it has wider application fields and better effect.

Working principle:

The motor brings along the central shaft to drive through the belt pulley. The lower part of the shaft connects with the hanger, on the frame is loaded with the roller equipment. The roller equipment does revolve around the central rotation, at the same time it revolves around the grinding rings, and it self also rotates on account of the rubbing effect. And the material will vertically fall down from the silo. After distributing, the material falls into the space of the rollers and rings to grind on account of the centrifugal force yielding from the extruding, thus get the powder.

Straight Centrifugal Grinder Technical Data

Model:MGZ605,MGZ806 ,MGZ1008

Feeding Size(mm):< 8 < 10 < 15

Final Products Size(mm):2.8-0

Capacity(t/h):3-5, 5-10, 14-20

Main Power(KW):8P-22 ,8P-37, 8P-75

Dimensions (Excluding Dust Filter)(mm):2600×1060×2250,2700×1400×2300,4000×2300×2700

For more information :Straight Centrifugal Grinder http://www.vipeak.cn/mofenji/ztmfj.html