1. What is a slurry pump?

The centrifugal slurry pump utilises the centrifugal force generated by a rotating impeller to impart energy to the slurry in the same manner as clear liquid type centrifugal pumps.

Slurry pumps need much wider and heavier impellers to accommodate the passage of large particles. They also be constructed in special materials to withstand the internal wear caused by the solids.

2. What advantage of AH slurry pump?

AH pumps are those of cantilever, horizontal and centrifugal ones, whose shafts can be sealed by packing seals or by centrifugal type seals.

The positions of the pump outlet can be positioned at an interval of 45°according to different requirements, so eight different angles can be applied by rotation in installation.

AH slurry pumps with good impeller size and design, its ease of maintenance, the type of shaft seal to be used and the choice of the optimum materials withstand wear caused by the abrasive, erosive and often corrosive attack on the materials. They can also be applied Multi-staged in series.

3. What mainly usage of AH slurry pump

Slurry pumps are widely used to transport corrosive/ abrasive and high concentration slurry in many industries. such as Gold, Silver, Iron ore, Tin, Steel, Coal, Titanium, Copper, Mineral sands, Lead and Zinc. Various other industries include Molybdenum, Electric Utilities, Oil Shale, Water & Sewage Utilities, Building areas, Sand & Gravel, Tobacco and Agriculture (hog, poultry, dairy manure).

Mining & Minerals, Grinding and screening, Hydrocyclone separation, Magnetic separation, Flotation, Thickening, Filtration, Leaching, solvent extraction and electrowinning, Pelletising, Tailings, Metallurgy, Roasting, Annealing and pickling, Coke quenching, Hot strip milling, Neutralisation, Mud handling and waste treatment

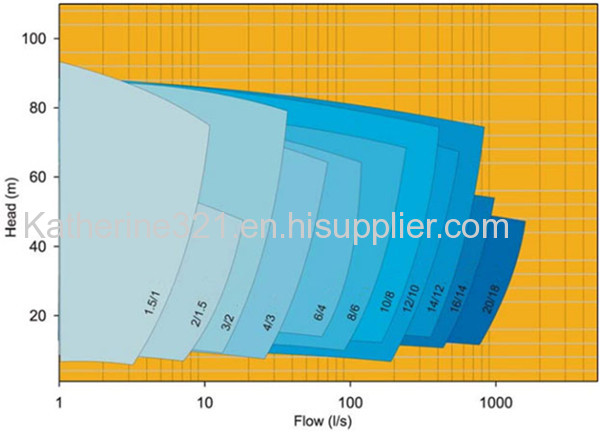

4. AH slurry pump selection chart

( Note: Approximate performance for clear water,to be used for primary selection only.)

5. Pump performance parameters

| Type | Allowable (Kw) | Clear Water Performance | Impeller | |||||

| Capacity/ Q m³/hr | Head/m | Speed/rpm | Max Efficiency | NPSH/m | Nos of Vane | Diameter /mm | ||

| 1.5/1 B-AH | 15 | 12.6-28.8 | 6-68 | 1200-3800 | 40 | 2-4 | 5 | 152 |

| 2/1.5 B-AH | 15 | 32.4-72 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 184 |

| 3/2 C-AH | 30 | 39.6-86.4 | 12-64 | 1300-2700 | 55 | 4-6 | 5 | 214 |

| 4/3 C-AH | 30 | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 5 | 245 |

| 6/4 D-AH | 60 | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 5 | 365 |

| 8/6 E-AH | 300 | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 5 | 510 |

| 10/8 F-AH | 560 | 612-1368 | 11-61 | 400-850 | 71 | 4-10 | 5 | 686 |

| 12/10 ST-AH | 560 | 936-1980 | 7-68 | 300-800 | 82 | 6 | 5 | 762 |

| 14/12 ST-AH | 560 | 1260-2772 | 13-63 | 300-600 | 77 | 3-10 | 5 | 965 |

| 16/14 TU-AH | 1200 | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 5 | 1067 |

| 18/16 TU-AH | 1200 | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 5 | 1370 |

6. Slurry pump construction drawing

7.Main part number at the drawing

| 032: Frame Plate 060: Intake Joint 132: Discharge Joint 083: Throatbush 110: Volute Liner 147: Impeller | 122: Stuffing Box Seal 036: Frame Plate Liner 013: Cover Plate 018: Cover Plate Liner 124: Volute Liner Seal 041: Frame Plate Liner Insert |

8. Materials of construction

| LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

| Standard | Chrome Alloy Natural Rubber | Chrome Alloy Natural Rubber | SG Iron | SG Iron | Chrome Alloy or SG Iron | Chrome Alloy or SG Iron | SG Iron | Rubber and Nitrile |

| Options | Ferralium Hastelloy C 316 SS W151 Polyurethane Neoprene Butyl Viton Nitrile EPDM Hypalon | Ferralium Hastelloy C 316 SS W151 Polyurethane Neoprene Butyl Nitrile Hypalon | SG Iron Various grades | MS Fabricated Cast Iron | NI Resist Ferralium Hastelloy C Polyurethane 316 SS W151 | NI Resist Ferralium Hastelloy C 316 SS Rubber W151 Polyurethane Neoprene Butyl Nitrile | EN56C Ferralium Hastelloy C Titanium 316 SS 304 SS | Ceramic Stellite Chrome Oxide Nordel Neoprene Viton |

We can produce many kinds of centrifugal slurry pump for mining ,sand and other solids slurry transporting.

9. Slurry Pump Spare Parts

Code | 1.5/1 BAH (R) | 2/1.5 BAH (R) | 3/2 CAH (R) | 4/3 CAH (R) | 4/3 DAH (R) | 6/4 DAH (R) | 6/4 EAH (R) | 8/6 EAH (R) | 10/8 FAH |

003 | B 003 M | B 003 M | C 003 M | C 003 M | D 003 M | D 003 M | E 003 M | E 003 M | FAM 003 M |

004 | B 004 M | B 004 M | C 004 M | C 004 M | D 004 M | D 004 M | E 004 M | E 004 M | F 004 M |

005 | B 005 M | B 005 M | C 005 M | CAM 005 M | D 005 M | DAM 005 M | E 005 M | EAM 005 M | FAM 005 M |

011 | B 011 | B 011 | C 011 | C 011 | D 011 | D 011 | E 011 | E 011 | F 011 |

013 | B 1013 | B 15013 | C 2013 | D 3013 | D 3013 | E 4013 | E 4013 | F 6013 | G 8013 |

015 | B 015 M | B 015 M | C 015 M | D 015 M | D 015 M | E 4015 M | E 4015 M | F 6015 M | G 8015 M |

017 | B 1017 | B 15017 | C 2017 | D 3017 | D 3017 | ||||

018 | E 4018 R | E 4018 R | F 6018 | ||||||

024 | B 024 | B 024 | C 024 | C 024 | D 024 | D 024 | E 024 | E 024 | F 024 |

028 | B 028 | B 028 | C 028 | D 028 | C 028 D 028 | DAM 028 | E 028 | EAM 028 | |

029R | B 029 R | B 029 R | C 029 R | CAM 029 R | D 029 RM | DAM 029 R | E 029 RM | EAM 029 RM | |

032 | B 1032 | B 15032 | C 2032 | CAM 3032 | D 3032 | DAM 4032 | E 4032 | EAM 6032 | G 8032 |

036 | B 1036 | B 15036 | C 2036 | D 3036 | D 3036 | E 4036 R | E 4036 R | F 6036 | |

041 | B 1041 NA | B 15041 NA | C 2041 | D 3041 | D 3041 | E 4041 | E 4041 | F 6041 | G 8041 |

044 | B 044 | B 044 | C 044 | C 044 | D 044 | D 044 | E 044 | E 044 | G 044 |

046 | B 046 | B 046 | C 046 | C 046 | D 046 | D 046 | E 046 | E 046 | F 046 |

052 | B 1052 | ||||||||

060 | B 1060 | B 15060 | C 2060 | D 3060 | D 3060 | E 4060 | E 4060 | G 8060 | |

061 | B 061 | B 061 | C 061 | C 061 | D 061 | D 061 | E 061 | E 061 | F 061 |

062 | B 062 | B 062 | C 062 | C 062 | D 062 | D 062 | E 062 | E 062 | F 062 FAM062 |

063 | B 063 | B 063 | C 063 | C 063 | D 063 | D 063 | E 063 | E 063 | G 063 |

064 | D 064 E 064 | E 064 | F 064 | F 064 | F 064 | ||||

067 | B 067 | B 067 | C 067 | C 067 | D 067 | D 067 | E 067 | E 067 | G 067 |

073 | B 073 M | B 073 M | C 073 M | CAM 073 M | D 073 M | DAM 073 M | E 073 M | EAM 073 M | FAM 073 M |

075 | B 075 | B 075 | C 075 | C 075 | D 075 | D 075 | E 075 | E 075 | FAM 075 |

076 | DAM 076 JM | ||||||||

078 | B 078 | B 078 JM | C 078 | CAM 078 | D 078 | DAM 078 | E 078 JM | EAM 078 | G 078 |

081 | E 4081 | F 6081 | |||||||

083 | E 4083 R | E 4083 | F 6083 | G 8083 | |||||

090 | B 090 | B 090 | C 090 | C 090 | D 090 | D 090 | |||

108 | B 108 | C 108 | D 108 | E 108 | F 108 | ||||

109 | B 109 | B 109 | B 109 C 109 | C 109 D 109 | D 109 | D 109 | E 109 | E 109 | F 109 G 109 |

110 | B 1110 NA | B 15110 NA | C 2110 NA | D 3110 | D 3110 | E 4110 | E 4110 | F 6110 | G 8110 |

117 | B 117 | B 117 | C 117 | CAM 117 | D 117 | DAM 117 | E 117 | EAM 117 | FAM 117 G 117 |

118 | B 118 | B 118 | C 118 | C 118 | D 118 | D 118 | E 118 | E 118 | G 118 |

122 | B 122 | B 122 | C 122 | D 122 | D 122 | E 122 | E 122 | F 122 | G 122 |

124 | E 4124 | E 4124 | G 8124 | ||||||

125 | B 1125 | B 15125 | C 2125 | D 3125 | D 3125 | ||||

127 | B 1127 NA | B 15127 NA | C 2127 | ||||||

132 | B 1132 XL | B 15132 L | C 2132 XLP | D 3132 XLP | D 3132 XLP | E 4132 XLP | E 4132 XLP | F 6132 XLP | G 8132 XLP |

138 | B 138 | B 138 | D138 | D 138 | D 138 | D 138 | D 138 | D 138 | |

147 | C 2147 | D 3147 NA | D 3147 | E 4147 R | E 4147 | F 6147 R | FAM 8147 | ||

217 | B 217 | B 217 | C 217 | ||||||

239 | FAM 239 M | ||||||||

241 | D 241 | D 241 | E 241 | E 241 | |||||

302 | E 4302 | F 6302 | |||||||

303 | E 303 | F 303 | |||||||

304 | E 4304 | F 6304 | |||||||

315 | E 315 |

10. Our service

| OEM service | Produce thepump and spare partsaccording toclient's drawing or sample. |

| Pump slection | Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. |

| Using service | Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. |

| Quality control | Pay more attention to the quality in every process with different instruments. |

| Material service | Interchangeable metal design allow best material choice for any application. |

| After-sales service | Provide lifetime after sale serviceto solve any question duringusesand large stock for standard spare parts. |

| Guarantee | One year guarantee for whole machine except of the wet end parts. |