Description:

Sawdust dryer refers to using screw conveyor to continuously add the powder shape wet sawdust into dry pipe. In conveying and dispersing of high speed heat flow, make wet materials' moisture evaporate, get powder or granular products' drying process. It is mainly made up by air heater, feeder, air flow drying tube, cyclone separator, fan etc.

Features:

1. Strong drying strength, as the materials in the air flow is high dispersion, particles' total area is the effective area of drying.

2. Short drying time.

3. Airflow dryer has features of simple structure, small floor area, easy to build and maintain.

4. Large handling capacity and high thermal efficiency. When drying together with the water, thermal efficiency can reach 60%.

Application:

Air flow sawdust dryer is widely applicable to straw press block fuel, charcoal machinery, sawdust pellet fuel, sawdust press block, farming and animal husbandry engineering etc. industry. Such as corn straw drying, soybean straw drying, cotton straw drying, wheat straw drying, sorghum culm drying, wood drying, wood chips drying, sawdust drying, ginkgo biloba drying, mulberry leaves drying etc. agricultural cellulose category etc, materials.

working principle of sawdust dryer:

Sawdust dryer is mainly composed of air heater, feeder machine, pneumatic drying pipe, cyclone separator and draught fan. The working process of this machine is that the spiral conveyor is used to continuously send the powdery wet sawdust into the drying pipe, and in the conveyance and dispersion of high-speed hot air, the water containing in the wet materials will evaporate, thus getting powdery or granular dry products.

Due to the unique structure of the sawdust dryer machine, the sawdust can be fully dried inside the rotating cylinder, and before going into the material conveyance pipe, the sawdust will be fully dispersed again, making the water more quickly evaporated. In addition, the baffle plate can block the impurities in the sawdust to ensure the quality of the sawdust that goes into the material conveyance pipe.

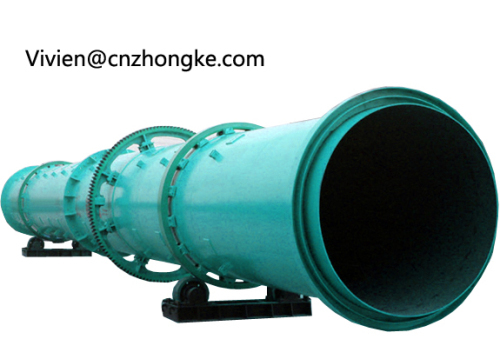

High density rotary dryer parameters

Model | Inside Dia. | Length | Gradient | Rotate Speed | Power | Capacity | Weight |

ZT-1.2X6.0/8 | 1.2 | 6/8 | 5.0 | 5.8 | 5.5 | 8-12 | 9380/10200 |

ZT-1.5X12/15 | 1.5 | 12/15 | 5.0 | 4.8 | 15 | 12-16 | 16450/18240 |

ZT-1.8X12/14 | 1.8 | 12/14 | 5.0 | 4.5 | 18.5 | 18-20 | 20000/2100 |

ZT-2.2X12/14 | 2.2 | 12/14 | 5.0 | 4.3 | 22 | 22-28 | 37100/38830 |

ZT-2.4X14 | 2.4 | 14 | 4.0 | 3.78 | 30 | 30-35 | 50700 |

ZT-2.4X18 | 2.4 | 18 | 4.0 | 3.0 | 37 | 35-40 | 54000 |

ZT-2.4X22 | 2.4 | 22 | 3.0 | 3.0 | 45 | 38-42 | 57000 |

ZT-2.8X20 | 2.8 | 20 | 4.0 | 3.7 | 40 | 45-55 | 71000/75000 |

ZT-3.0X22/25 | 3.0 | 22/25 | 4.0 | 3.2 | 75 | 58-70 | 88000/95000 |

ZT-3.2X25 | 3.2 | 25 | 4.0 | 3.0 | 110 | 75-90 | 166000 |

ZT-3.6X25 | 3.6 | 25 | 4.0 | 2.7 | 132 | 95-110 | 188000 |

About us:

Henan Zhongke Engineering & Technology Co., Ltd. since its inception has been to customers to provide quality and efficient service. Production jaw crusher, counter type crusher, hammer crusher, vibrating screen set of sand production line, aeratedconcrete equipment deep customer satisfaction. Our caring service, careful manufacture, price satisfaction, let customer feel rest assured . "Customer oriented", provide overall service for the customer; "to serve as the core", for customers to create the most valuable products. "Take the quality as the center", a full range of services to customers.