Applicability

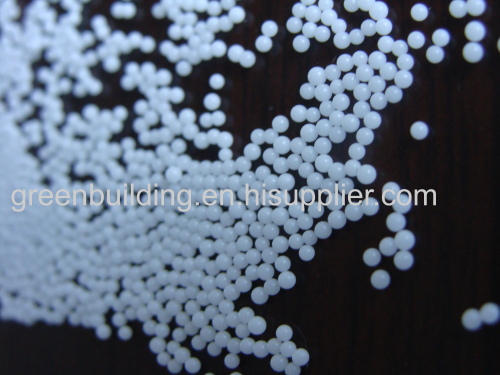

PKF-XB has a standard expansion ratio that result in a relative light density after a single expansion and even lighter densities after several expansion. It can be widely used in machinery and electronic products packing, agriculture and fish boxes, thermal insulation and heat preservation material in building, fishery flotation buoys, crafts, food and drinking container, decorative material, lost foam casting and light apparatus with resistance to attack.

Product Specification

Specification | Bead size (mm) | One-time Expansion | Allication |

PKF-301XB | 1.00-1.60 | 70-90 | Block |

PKF-302XB | 0.85-1.25 | 65-85 | Block and large packaging |

PKF-303XB | 0.70-1.00 | 60-75 | Block and medium-density |

PKF-401XB | 0.50-0.80 | 55-70 | Packaging for tiny article and heavy product |

PKF-501XB | 0.40-0.60 | 50-65 | Cushion for blow molding, casting |

PKF-601XB | 0.30-0.50 | 35-50 | Fine product and casting |

Storage Notice

●The storage temperature of EPS should be below 25℃ with good ventilation.

●EPS contains combustible and volatile blowing agent, which slowly dissipates in storage. Raw beads, foamed heads and molding should be strictly segregated from fireworks, static electricity or sparks to avoid danger.

●Use fresh raw material to ensure stable operation and good product.

Recommended

●The use EPS needs to have products of pre-expansion, maturing stage, block molding and shape molding.

A. Pre-expansion

Pre-expansion XB grade EPS beads by heating above 92℃ with steam in a continuous or batch pre-expander. The process is conducted until the volume or density reaches the required level. A stable and uniform pre-expansion ratio ensures stable molding conditions and the quality of molding can be guaranteed. As each pre-expansion situation is different the operation requires a high degree of operators experience and skills. Proper and careful adjustment of the pre-expansion temperature, steampressure, feed volume and outlet height will result in an ideal outcome. In order to achieve a higher ratio, a second expansion is acceptable, during which the temperature should be in the range of 80-90℃.

B.Maturing

The pre-expansion form has internal vacuum and is soft and poorly elastic because of the evaporation of blowing agent. Air must therefore be allowed to diffuse into the heads until the inner & outer pressure are equalized and the elasticity is restored. This step normally requires around 4hours for completion. Should there be a need for a second expansion and then the interval should not exceed 3 - 5 hours after the first. The conditioning chamber used to age the pre-expansion should be fitted with an anti-static gauze net in favor of water dissipating from beads and eliminating static naturally accumulated by friction. Good ventilation will aid maturing.

In order to avoid the pre-expaned mass from collapsing during blowing, the pre-expaned mass should be allowed to fall freely into the holding chamber. If conditions permit, the beads should be allowed to stabilize a little to ensure round beads and shorten the maturing time before being transferred into the silo.

C.Molding

After being filled into molds, the stabilized beads are steamheated to shape and to achieve a tough but water proof light structure with close fusion and airtight pores.

Improper molding conditions or operations may lead to shrinkage, a glossy surface, difficult mould release, poor fusion, brittleness and a high failure rate.

The supply condition of steam, cooling water and compressed air is the foundation for ensuring easy removal from moulds, uniformity, a beautiful surface and shortened mould cycles.

Ideal condition are:

Main Steam Pressure:0.4-0.7MPa

Cooling Water Pressure:0.3-0.5MPa

Compressed Air :0.45-0.70MPa

Vacuum Degree:-600-650mmHg

Operator experience is also critical, as the operating conditions require skilled judgment conditions to achieve best results for each product.

D.Shape Molding

After removal from moulds, water adheres to the product surface. At the same time, the beads experience a vacuum after cooling and great shrink.

Products with relatively high expamsion ratios may experience shrinkage on thin sections so they require drying to improve rigidity and intensity and intensity after storage or exposure in heating room.

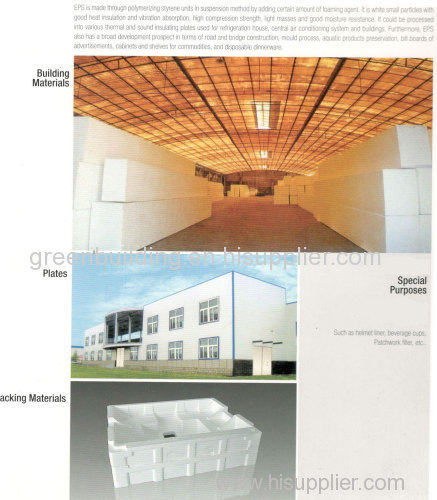

Application