Production Describation

Dreservation Line shot blasting machine.

Dreservation line shot blasting machine is mainly used for steel, structural steel cleaning and clean up the scale. In addition, also with a scale shot blasting and cleaning up residual coating of other metal parts. Steel processing width 0.4-6.5 meters. Length 0.5-30 meters. Thickness 3-150mm.

Blasting equipment package includes a room, abrasive control unit, blasting systems, abrasive recycling sorting storage system, abrasive purge unit, ventilation and dust removal system, roller conveyor, electric control system, service platform, security systems. Mechanical, electrical system should be equipped with reliable security protection devices. The shot blasting equipment complies with European Union CE, Germany TUV, and France BV related standards, certification and requirements.

Blasting chamber

Blasting room with welded steel frame and steel plate, with sufficient strength and rigidity. To prevent direct projectile projectile chamber body: the main cast blasting room area lined with rolling high manganese SMn13 boards, thickness 10MM

To prevent the projectile hit the funnel, in addition to the bottom surface blasting chamber is equipped with a combined network of cast iron plate, laying steel mesh sieve screen, prevent flash burr and bulk materials into the blast wheel. Slip pill bucket inclined surfaces are blocking pill means projectile covering the surface of the funnel slide pill, to prevent direct contact with the projectile slip pill Doudou wall, reaching the hopper maintenance purposes.

Spiral blasting chamber interior region above the feeder is designed with a protective cover. Protective cover designed to facilitate the installation in the form of free abrasive spilled. Blasting Room and export channel rubber seal curtain. By separating the dust from the blasting chamber is withdrawn to prevent foreign particles clogged filter cartridge.

Workpiece conveying system

Roller conveyors need to use an external dust-proof bearings. By continuously variable geared motor centralized control, reversing movement can claim. Roller conveyor speed can be adjusted by frequency converter can also be adjusted by the potentiometer on the control cabinet.

Located direct throw hit the region conveyor rollers made of high wear resistant material.

Blow cleaning room

After blasting clean the surface of the steel projectile is more critical issue, according to our experience in numerous plate pretreatment project practice in the process of accumulation, combined with foreign advanced technology products, the use of a rolling sweep plus breeze blowing way:

A cleaning were using the traditional high-strength nylon brush + income pill spirally

Two wind turbine high pressure chamber after the cleaning using high-pressure air curtain blowing pill

Precipitators, bag-type sub-pulse and pulse cartridge in two ways, according to user requirements

Consistion and Features

Dust collectoe is consists of :the entity framework, cartridge device, pulse-jet system, discharging device and other components.

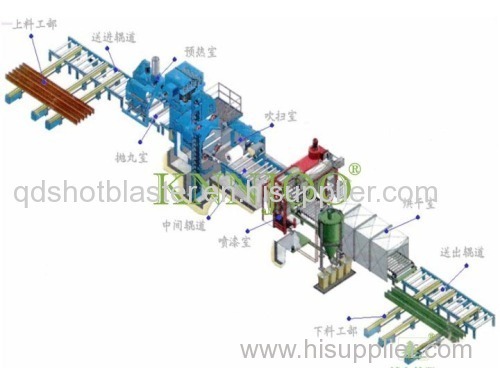

2,Dreservation Line.(Preheating, shot blasting, painting and drying)

KNNJOO dreservation line shot blasting machine means steel surface before machining shot blasting and coated with a protective primer processing technology. After pretreatment of steel products to improve the mechanical and corrosion resistance of the metal member, to improve the fatigue resistance of the steel sheet, extending its life; and to optimize the production process of steel surface state, in favor of CNC cutting machine cutting and precision blanking. Furthermore, since the steel before processing shape comparison rules, in favor of mechanical descaling and automated paint, so the use of steel pretreatment can greatly improve the efficiency of clean-up operations, reduce labor intensity and pollution clean-up operations on the environment. Steel plate pretreatment line shot blasting machine sliding on the main discharge, the discharge roller, preheating, nine parts consisting of shot blasting, painting, drying, automatic monitoring systems, efficient dust collector, electric control. The entire production line by Siemens PLC programmable control, using a shift register and the photo detector, automatic measurement of plate thickness and width automatically adjust the lift height and width projectile cleaning device.