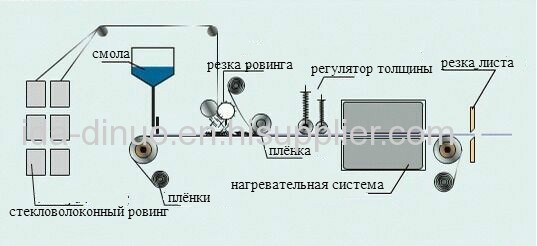

FRP lighting sheet double-layer production line

Machine fuction: this production line is able to produce lighting sheet, color sheet, common plane sheet and gel coat sheet (make on demand).

Basic parameters:

Operation staff: 4-7people Production speed: 2-8m/min

Sheet width: Maximum effective width for flat sheet is 1500mm

Wave height: Maximum 130mm

Sheet thickness: 0.4-4.0mm Machine main dimension : 30m×5.6m×6m

Power requirement: 80-110kw

Power consumption:Actual running power consumption is 25-45kw/h

Features of equipment:

1, Double-layer layout structure, lower the requirement on length of plant.

2, Impregnation platform have multi-line independent temperature control, temperature control is more precise, able to adapt the changing of ambient temperature, speed of impregnation is fast, speed of production is improved effectively.

3, Easy operation based on PLC intellectual control system. Computer control, the production task and equipment operating data is faster and intuitional. Only short-term training can make operators complete production independently.

4, Unique temperature control chamber and temperature control arithmetic makes oven heating fast, temperature control precise. Which improve quality of products, reduce energy consumption and shorten the preparing time effectively. This way makes sheets curing better.

5, Roving chopper speed can be synchronous with the production line.

6, Special cross cutting machine and good synchronization performance make cutting accurately..

7, All the machine parts adopt international standard steel make machine with high stability.

8, System failure can be automatically alarmed and show fault point. Make maintenance easily.

9, Particular parts adopt special purpose wire, durable in use.

10, Size and layout of machine can be made according to customer requirements