Basic Info

· Model NO.: AH HH

· Max. Capacity: >400 L/min

· Impeller Number: Single-Stage Pump

· Influent Type of Impeller: Single Suction Pump

· Pump Casing Combined: Vertical joint Surface Pump

· Impeller: Closed

· Transport Package: Wooden Case

· Max. Head: >150m

· Driving Type: Motor

· Working Pressure: Low Pressure Pump

· Position of Pump Shaft: Horizontal Pump

· Mounting Height: Suction Centrifugal

· Usage: Pump, Ash Pumps, Mining

· Origin: Hebei

Product Description

· Pump Introduction

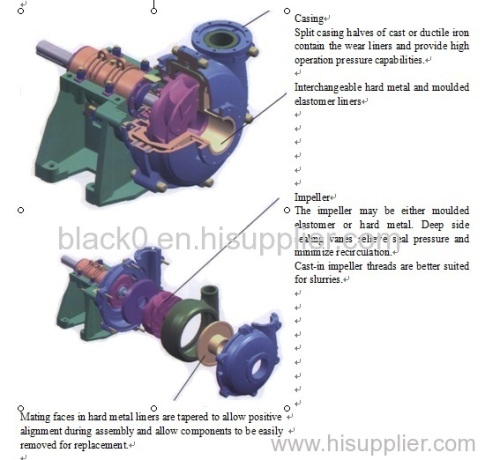

WA series are cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps.

They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

Typical Applications

SAG mill discharge, ball mill discharge, Rod mil discharge, Ni acid slurry, coarse sand, coarse tailings, phosphate matrix, minerals concentrate, heavy media, sugar beet, dredging, bottom/fly ash, lime grinding, oil sands, mineral sands, fine tailings, slag granulation, phosphoric acid, coal, flotation, process chemical, pulp and paper, FGD, cyclone feed, etc.

Features

The frame plate for WA series pumps has interchangeable hard metal or pressure molded elastomer liners. The impellers are made of hard metal or pressure molded elastomer liners.

The shaft seals for WA series can be packing seal, centrifugal seal or mechanical seal.

The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

Pump Part Material

Part Name | Material | Specification | HRC | Application | OEM Code |

Liners & Impeller | Metal | AB27: 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

AB15: 14%-18% chrome white iron | ≥59 | Used for higher wear condition | A07 | ||

AB29: 27%-29% chrome white iron | 43 | Used for lower pH condition especially for FGD. It also can be used for low-sour condition and desulfuration installation with pH no less than 4 | A49 | ||

AB33: 33%-37% chrome white iron | It can transport oxygenated slurry with pH not be less than 1 such as phospor-plaster, nitric acid, vitriol, phosphate etc. | A33 | |||

Rubber | R08 | ||||

R26 | |||||

R33 | |||||

R55 | |||||

Expeller & expeller ring | Metal | B27: 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

Grey iron | G01 | ||||

Stuffing Box | Metal | AB27: 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

Grey iron | G01 | ||||

Frame/Cover plate, bearing house & base | Metal | Grey iron | G01 | ||

Ductile iron | D21 | ||||

Shaft | Metal | Carbon steel | E05 | ||

Shaft sleeve, lantern ring/resctrictor, neck ring, gland bolt | Stainless steel | 4Cr13 | C21 | ||

304 SS | C22 | ||||

316 SS | C23 | ||||

Joint rings & seals | Rubber | Butyl | S21 | ||

EPDM rubber | S01 | ||||

Nitrile | S10 | ||||

Hypalon | S31 | ||||

Neoprene | S44/S42 | ||||

Viton | S50 |

·

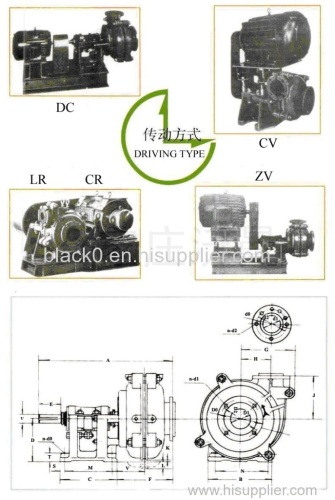

DRIVE TYPE

Our factory has passed ISO9001:2008 international quality management system certification .We have full set quality control system and testing system to guarantee best product quality.

Packaging detail:

(1) Wooden case

(2) Can be packed as per customer requirement

(3) Usually can load 10-20 pieces into one 40HC container

Delivery time: within 15-30 working days

Please search "CNSTARCK or PRIME " from Google for more information.