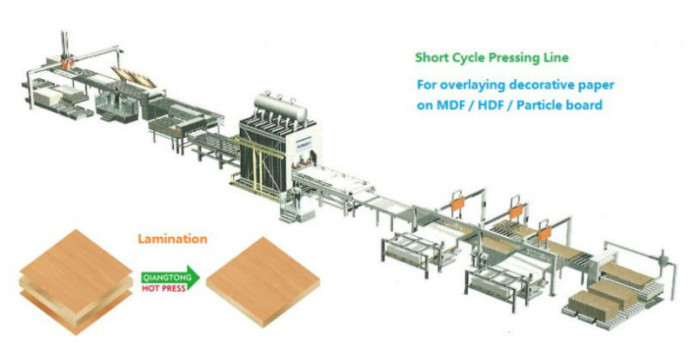

Decorative paper +fiberboard

Start the control button,the substrate is placed in middle of the platform. Place the decorative paper on upside of substrate, make sure the paper covers entire surface of the substrate.

Start the horizontal control button, while using the hand gently press the composite slab corner, the belt conveyor will move forward to the longitudinal lifting conveyor, which will deliver the composite slab into hot press for laminating.

Forklift roller table, lifter, board-pushing machine, dust-removal machine, central positioning belt machine, vacuum sucker, loader, hot press , unloader, trimmer, cooling shelf, stacker.

(1)Forklift roller: The worker put raw boards on the roller table

(2)Lifter: The forklift roller transport raw boards to lifter, then lifter will go up to same height of board pushing machine.

(3)Board pushing machine: Push the raw board into dust removal machine one by one.

(4)Dust removal machine: Remove the dust on raw board surface, push it to central positioning belt machine.

(5)Central positioning belt machine: Correcting position of raw board.

(6)Vacuum sucker: Suck the raw board to the loader where the workers have paved one melamine impregnated paper.

(7)Loader: The workers will pave another piece of melamine impregnated paper on raw board, then the loader deliver sandwich structure into hot press .

(8)Hot press includes frame, hydraulic station, hot platen, oil cylinder, press plate, cushion pad etc.

A, Frame:①Aging,eliminate internal uneven pressure, improve service life of frame.

②Frame is milled by CNC Milling Machine, the surface is very smooth and can reduce the friction during operation press.

B, hydraulic station: ①Upgrade the original hydraulic system,change it to one plunger pump. Reduce noise and failure rate.

②Through the large diameter filling valve,high precision proportional valve. Ensure rapid opening and closing, and reduce the impact and vibration at the same time.

C, Hot platen: Low heat energy consumption, uniform thermal conductivity

E, Oil cylinder: ①Adding the lifting cylinder is to increase pressing speed.

②High and low fuel tank combination, to ensure production efficiency.

F, Press plate: It is an auxiliary part of the hot press, can deal with the surface structure of Laminated flooring.

D, Cushion pad: It is the wearing part of the hot press, is installed between hot platen and press plate. Generally the material is copper mesh, to protect press plate and heat conduction evenly.

After heating and pressing, press the paper and the raw board together.

(9)Unloader: Suck out the finished board

(10)Trimmer: Clearing rough edge around the finished board.

(11)Cooling shelf: cooling

(12)Stacker:After cooling, stacking by vacuum sucker one by one.