Founded in 2006,Maanshan Durmapress CNC Machinery Co.,Ltd is located in the Maanshan

city ,Dangtu County,close to Nanjing Airport. Our geographical position is superior and the

transportation is very convenient. We have more than 320 employees, including all types

of engineering and technical personnel, serving the company R&D, production, and

customers' service. At the same time, we have our own sales companies in each major

and medium city.

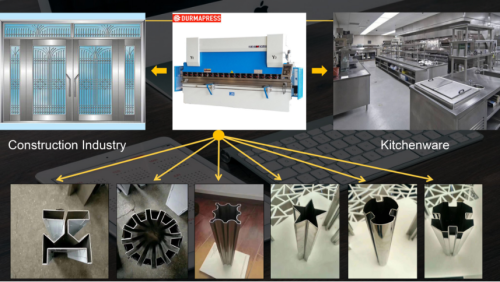

Product Name: Durmapress High Quality CNC hydraulic press brake, Bending machine,

Hot sale hydraulic press brake

Product Application

The folded sheet metal bending machine has high productivity and high working accuracy,

using different shapes of up and down mould, can be bent into various shapes artifacts,

slider stroke at a time can be to a bending forming of sheet metal, after a lot of bending

can be achieved relatively complex shape workpiece, when equipped with the

corresponding equipment, can also make a punch and so on.

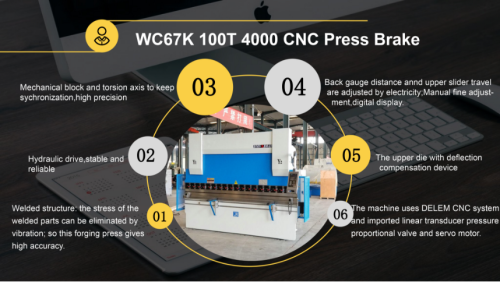

1. Main Features:

Brand-new industry design combined with modern aesthetic concept, high-quality

production technology, simple appearance.

Latest high-frequency responding hydraulic control technology, faster, more efficient

and accurate.

Heat treatment of the rack, rigidity optimization verification on entire machine and the

application of hydraulic compensation structure jointly ensure the bending precision

of MB8 series Press Brakes.

Optimal ratio of parameters and top-level core configuration ensure stable performance,

and easy operation.

MB8 standard 2 shafts back gauge system, as to complex shape work pieces ,4 or 5

shafts back gauge system and corresponding dies are available for your option.

Press Brake using fully closed-loop electro-hydraulic servo control technology, slider

position signals can be feedback to NC system by bilateral gratings, then NC system

adjusts the amount of fuel tank by changing the synchronous valve opening size,

hereby controlling the slider(Y1,Y2)running on the same frequency, maintaining the

parallel state of the worktable.

According to state of sheet metal on the Press Brake, CNC system can automatically

control the table deflection compensation yielding uniform length of all workpiece

angles.

The use of hydraulic deflection compensation gives access to uniform full length

workpieces . Hydraulic deflection compensation consists of a set of oil cylinders

under the worktable, which can make the table occurs relative movement and form

an ideal convex curve, ensuring the relative position relations with slider keep

unchanged. Compensation values are subject to plate thickness and properties of

material to be cut.

2. Main Configuration:

CNC system adopts Netherlands DELEM DA52S

Grating ruler controls depth Y1 and Y2 axis(y1/y2-axis 0.01mm)

Servo motor drive and control X axis(X-axis 0.01mm), manually adjusts R axis up

and down, fingers can easily move along the cylindrical guide.

Keep the accuracy between HIWIN ball screw and linear guide within 0.01mm

Front carrier can be adjusted along the linear guide in the worktable direction

Germany Rexroth closed-loop electro-hydraulic servo synchronously controls the system

Germany EMB oil tube connectors

Germany Siemens main motor

France Schneider Electrics

Hydraulic and electrical overload protection

Upper are mechanical fast pinching dies. Lower are double-V quick changing dies

3. Safety Standard:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

Front finger protection device ( safety light curtain )

South Korea KACON pedal switch ( 4 security grade )

Metal safeguard, CE standard

Safety relay monitors completed with foot switch, safety protection devices

Safety standard(2006/42/EC)

4. Holland Delem DA52S Controller:

8″wide-frequency colored screen

Max 4-axes control (Y1, Y2, two additional axes )

266MHZ processor, memory capacity of 64M

Die library, 30 upper dies, 30 lower dies

USB memory interface, RS232 interface

Real-time Windows operating platform to ensure the stability of the operation, support

instant shutdown

One-page parameters for quick editing, navigation shortcuts

Automatically calculate deflection compensation

Micro switch panel, data editing

Automatically calculate the bending pressure and die safety region

Online operation analysis tool, Diagnostic Dashboard, angle calibration database

Model | WC67K 100T 4000 |

Normal Pressure | 1000mm |

Worktable length | 4000mm |

Distance between holes | 3000mm |

Depth of throat | 320mm |

Ram travel | 150mm |

Max opening height | 400mm |

Main power | 11KW |

Weight | 8400KG |

Overall dimension | 4400*1600*2700MM |

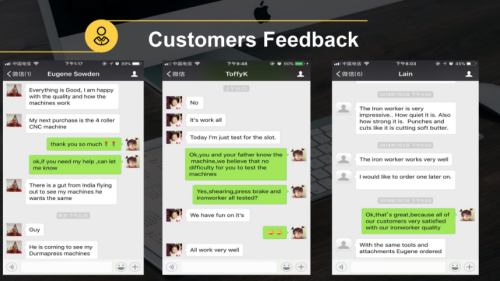

our service

1.Installation Service

We dispatch technician to customer's factory for installation and preoperation of machines.

(Customers only need to pay for the airfare and hotel expense.)

2.Training Service

Our technician is available to your factory and offer training of how to use our machines.

As well, you may send your technician to our company to learn how to operate machines.

( Customers only need to pay for the airfare and hotel expense.)

3.Quality Guarantee

We arrange a final test before shipment. We will make shipments after making sure

machine is in the best performance.

Machine warranty is 5 year.

RFQ

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please

kindly tell us your nearest port or address with postcode. we have reliable shipping

agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant