Product Description

Application

Hydraulic shearing machine is used to cut different metal materials, such as iron, mild steel, stainless steel, aluminum alley, galvanized plate...... Different material with different tensile strength and should choose different kinds of capacity and model machine.

It is very widely used in aviation, light industry, metallurgy, chemical engineering, construction trades, ships, auto, electric power and engineering, decoration, doors & windows making and so on.

Depends on different material, thickness and length, the shearing machine can be made to different size, capacity and design.

Hydraulic shearing machine can generally be divided into five categories

1. QC12Y Series Hydraulic NC Swing Shearing Machine

2. QC12K Series Hydraulic CNC Swing Shearing Machine

3. QC11Y Series Hydraulic NC Guillotine Shearing Machine

4. QC11K Series Hydraulic CNC Guillotine Shearing Machine

5. Special Industry and Required Shear

Performance Characteristics

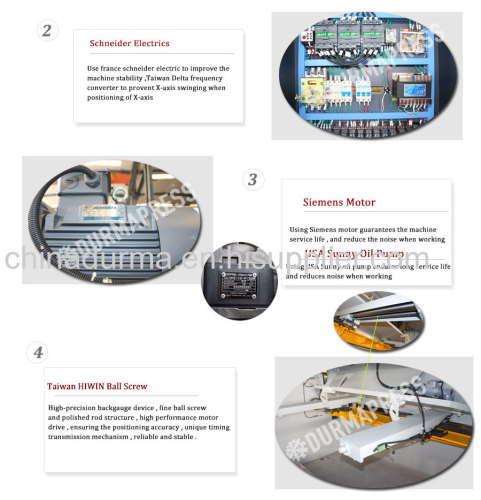

1. With optional programmed controller system Chinese famous ESTUN E200PS or Netherlands DELEM DAC310

2. Adopt linear guide,ball screw and servo motor driven back gauge to ensure the accuracy

3. All main parts of this machine such as worktable, wallboard,top blade rest, etc. are adopting steel plate welded structure

4. Hydraulic transmission cutting

5. Nitrogen cylinder driven returning stroke with stable operation, low noise, and well rigidity

6. With electric driven back stop structure and mechanical worm wheel-worm transmission control with low noise and high precision

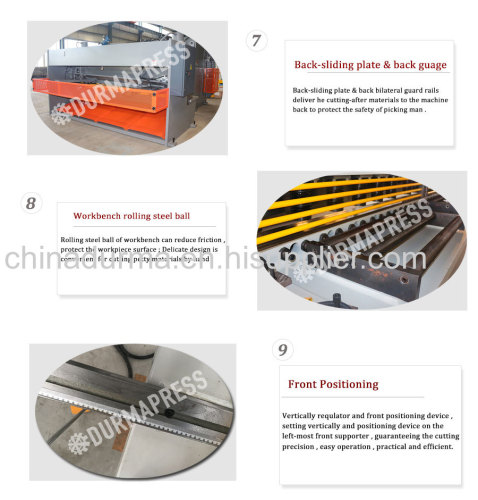

7. Adjustment blade gap board to adapt different thickness plates

8. Safety protection fence and warning tape

Advantages

1. Straightness:Within 3 meter error within 0.10mm

In the same industry product error 0.5-1mm

2. Cutting times 50% faster than the same industry.

For example:4*2500 shearing machine,our company product 30 times/min,in the same industry product only 12 times/min.

3. Machine body intensity,high precision processing equipment,holistic processing,the machine body will not be deformation in 10 years.

4. Blade material:6CrW2Si

Heat treatment: 55°-60°HB

5. Low noise,gear pump drive by hydraulic,70bd.

6. Emergency stop foot pedal increase the security protection,explosion -proof power supply switch cord.

How to choose the machine model?

The main required information is the material,cutting thickness and cutting length.

The maximum cutting thickness is only applicable to carbon structural steel plates with the tensile strength of 450 MPa; if it is used to cut metal plates with relatively high tensile strength such as manganese steel, stainless steel, etc., the maximum shearing thickness shall be less. Thus, when using the shear, the thickness of plates shall be strictly controlled by the operators themselves in accordance with the value of tensile strength of plates.As the cutting angle of this series is fixed,it can not be adjusted according to big thickness difference,usually it is widely used with the thickness of 0.2-16mm.Above 16mm thickness you can choose QC11Y series.

Then,according to the thickness of different material,you can choose the suitable length for yourself.With all of these you can go to the technical parameters table to find the right model and details.

Detailed Images

Technical Parameters

This series shear is mainly used to cut metal plates with the thickness of 0.2-40mm and different shearing length.It will come with Computer Numerical Control(CNC) operation system and ball screw,linear guide and servo motor driven back gauge to ensure the position accuracy.

Packing Details

1. Outside package is standard export wooden case.

2. Inside package is stretch film with three layers winding in surface to avoid crash during the transportation.

3. As the clients requests.

F&Q

1. Advanced Techinology

We provide our customers with all type of indigenousn CNC machines with good quality.

2. Non-standard machines

Most requirements for non-standard metal processing machines is easily fulfilled by giant cnc machinery, due to its vast knowledge and links in the industry.

3. Payment

We can accept T/T, L/C, West union,the best way is T/T payment, you can choose yourself, if you want other payment terms please let us know when you place the order.

4. After-sales service and techinical assistance

We provide overseas & domestic after-sales services and techinical assistance as per the customer requirements and needs.

5. Shipping

six independent giant workshops guaranteed the high efficient production, we will arrange the shipment within 3workdays after your full payment has been confirmed, and we have established long-term cooperation relations with reliable shipping forwarders which also promised the delivery time.

6. Cost saving

We are directly manufacturer, so there are no intermediary costs involved.

7. Return & Warranty

All our machines are inspected and tested before shipment, if you are not satisfied with the purchase, you can return the whole equipment in one week,all return items must be in its iriginal conditions, including packing case and accessories and so on. All our machines carry a full 3 year whole & parts warranty.