CNC PRESS BRAKE

The press brake machine is a kind of machine capable of bending the thin plate. The structure

mainly comprises a bracket, a worktable and a clamping plate, the worktable is arranged on

the bracket, the workbench is composed of a base and a pressure plate, the base is connected

with the clamping plate The base is composed of a seat shell, a coil and a cover plate. The coil

is arranged in the depression of the seat shell, and the top of the depression is covered with a

cover plate. The coil is energized by the conducting wire when in use, and the gravitation force is

generated on the pressure plate after electrification, thereby achieving the clamping of the sheet

between the pressure plate and the base. As a result of the use of electromagnetic force clamping,

making the platen can be made of a variety of workpiece requirements, but also to have the

workpiece sidewall processing, the operation is also very simple.

1.Main Features

1) hydraulic drive, the machine at both ends of the cylinder placed in the slider, direct drive

sliding work.

(2) the use of mechanical block structure, stable and reliable.

(3) slider stroke maneuver fast tune, manual fine-tuning, counter display.

(4) the use of all welded structure, with sufficient strength and rigidity.

(5) The slider synchronization mechanism uses the torsion axis forcing synchronization.

(6) wedge-shaped deflection compensation mechanism to ensure a higher bending accuracy

2. Main Configuration

Estun E200P controller

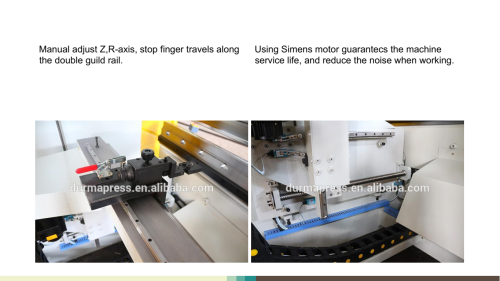

Controller controls and adjusts Y-axis and X-axis

Servo drive and control positioning of X-axis and Y-axis

Adopting HIWIN ball screw and linear guide rail, accuracy 0.05mm

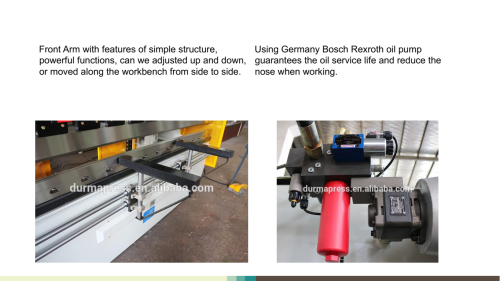

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

3. Safety Standard:

EN 12622:2009 + A1:2013 2.EN ISO 12100:2010

3.EN 60204-1:2006+A1:2009

Front Finger protection ( safety light curtain )

South Korea KACON pedal switch ( safety grade 4 )

Back metal safeguard, CE standard

Safety relay monitor pedal switch, safety protection

Safety standard ( 2006/42/EC)

Model | WC67K-160T/3200 |

Nominal force | 1600KN |

Worktable length | 3200mm |

Throat depth | 320mm |

Stroke | 200mm |

Poles distance | 2500mm |

Max open | 460mm |

Power | 11KW |

Bending thickness | 6mm for mild steel |

Dimension | 3200*1700*2700mm |

RFQ

Payment Terms:

T/T, L/C at sight are acceptable by us.

Guarantee period:

Our product quality guarantee period is 13 months from B/L date. During guarantee period,

we will provide spare parts without any charge in case of quality discrepancy caused by us.

If the malfunctions are caused by customers' incorrect operations, we will provide customers

spare parts at cost price. We also can offer flexible extended warranties according to the

actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition

of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn,

your engineers can come to our factory for learning the installation, operation and maintenance

for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee

the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the

clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can

offer professional recommendations; reg. non-standard products, we can offer professional

designing.