JH21 Series Punching Press

Product Description

Features:

» Crank drive type, gear engagement. » Steel welded body with high rigidity. » Auto lubrication system. » PLC electrical control system, powerful human interface. » Combination of dry clutch and brake system. » Six sides guide rail on the machine body. » Die set height is adjustable, speed is about 40mm/min. » Die adjust, pressure, hydraulic protection and slide stroke have interlock control. » It has T grooved for installating of die. » With water division filter to avoid water into pipe. » Pneumatic single balance cylinder, the pressure can be adjusted by hand. |

Main Equipments Manufacturer:

Main motor: Siemens PLC: Siemens A.C.contactor: Siemens Intermediate relay: Siemens Clutch brake: Italy/Shanghai Thermal relay, auxiliary fitting: Siemens Control button: Siemens Hydraulic overloading pump: Japan Two-hand buttons:Japan/France Bearing: Japan Air switch: Siemens Photo-electric safety device: LNTECH Touch display screen: Yinglun |

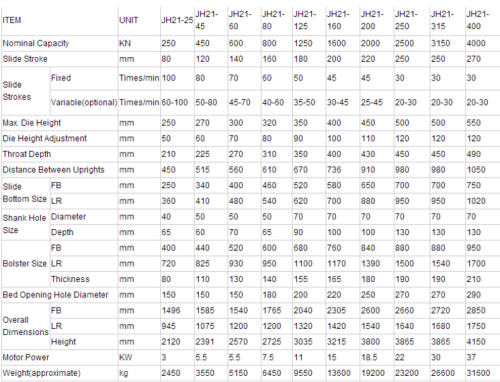

Specifications

1.CNC high precision press,the press accuracy is around 0.03mm,the noise criterion is around 70dB;

2.Welded steel plate frame, c framework,high frequency quenching and tempering,high intensity and rigidity;

3.The parts are processed by CNC boring and milling machine,the gears are processed by German gear grinding machine.The crankshaft,gear tooth and other friction parts are made of alloy steel,annealing process.

4.Electric cam device,die height adjustment 0.01mm,Six-side long rectangle guides of the ram with high accuracy;

5.PLC electrical control system,Hydraulic overload protection device,transmission output axle.

6.Pneumatic dry-friction clutch & brake, low noise, and long service life(wet clutch&brake is available).

7.Delta PLC,Italy OMPI clutch & brake,Japan TACO double solenoid valve,Japan NSK bearing, oil seal,Taiwan Kingair OLP protector bump,etc.

8.Emergent stop, inching, single and continuous movement.

Certifications

CUSTOMER VISIT

Our Service

Quality and Service Assurance:

1.we have Q & C department in our factory and our engineer have much experience and can design the suitable machine for our clients.

2.our machine can produce the nice production, can guarantee good quality.the production is confirm to the national standard even the international standard

3.the products should not have scratch and the flatness

Technical R & D Department: design teams for different kind of production line.

package:

1.As to the roll forming machine's package, it should be nude.

2.we'll protect the machine well before shipment, to prevent machines from rusting and damage.

Repairs:

Warranty: 1 year since the date of B / L on

Installation and Commissioning:. We will send professional engineers to buyers' country for installation and commissioning Buyer pays each engineer 100USD / Day besides the round-tickets, room and board.

OUR TEAM

DURMA SUCCESSFUL CASE

DURMA OFFICE

Packing & Delivery

RFQ

Payment Terms:

T/T, L/C at sight are acceptable by us.

Guarantee period:

Our product quality guarantee period is 13 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers' incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.