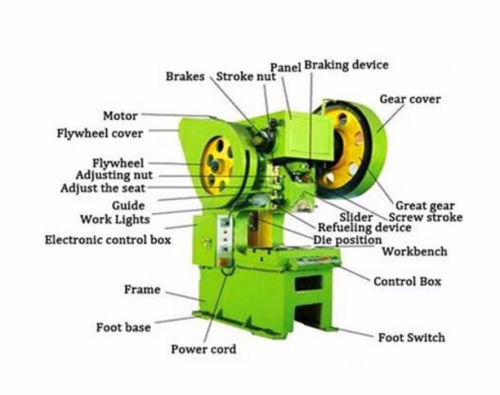

Mechanical power press/punching machine/punch press

Characteristics of JS21 Series Punching Machine

1. Our JS21 series punching machine adopts special integrated cast iron alloy, with high rigidity and shock resistance;

2. Slider: long guide way design, with slider balance device, to ensure the operation precision and stability;

3. All anti-wear components are connected electronic timing automatic lubrication system (in the case of lack of lubricant, pressing machine will be automatically and completely shut off);

4. Advanced, simple control system to ensure the accuracy of slider running and stopping.

Advantages of JS21 Series Punching Machine

1. Balanced center of grivity:

(a). Transmission center and the whole machine centers tend to be consistent, to assure the stamping precision and stability.

(b). This machine adopts the two slider balancers to ensure that the machine keeps balanced operation.

2. Reliable and safe operation:

The highly sensitive clutch / brake device, coupled with top international double solenoid and overload protection devices, assures the accuracy and security of sliders running and stopping in the pressing machine.

3. Slider adjusting mechanism:

Adjustment precision is up to 0.1mm, to deliver a safer and quicker production adjustment.

4. High precision:

Parts like crankshaft, gears and gear shaft, subject to friction have been through hardened heat treatment before grinding processing, to deliver high wear-resistance, balance and stable performance.

5. Automation and labor saving:

JS21 series punching machine can work with any automatic feeder, to deliver automated production, thus to reduce costs and improve efficiency.

| JS23,JS21 Special Deep Throat open pressure machine parameter list |

| Technical Parameter | Model | Deep Throat | |||||||||

| JA23-12 | JA23-16 | JA23-25 | JS21-25 | JS21-30 | JS21-40 | J21-40 | JS21-63 | JS21-125 | |||

| Nominal capacity | KN | 120 | 160 | 250 | 250 | 300 | 400 | 400 | 630 | 1250 | |

| Length of stroke | mm | 50 | 56 | 60 | 60 | 70 | 90 | 90 | 120 | 140 | |

| Strokes | times/min | 150 | 138 | 120 | 120 | 120 | 65 | 65 | 50 | 45 | |

| Max mold height | min | 150 | 180 | 200 | 200 | 200 | 230 | 230 | 260 | 280 | |

| Slide adjustment | degree | 30 | 30 | 35 | 35 | 45 | 50 | 50 | 50 | 100 | |

| Max inclination ofmain frame | mm | 20 | 20 | 20 | / | / | / | / | / | / | |

| Bolster area | Fb | mm | 220 | 260 | 310 | 310 | 350 | 420 | 420 | 510 | 1080 |

| Lr | mm | 370 | 390 | 490 | 490 | 560 | 670 | 670 | 780 | 710 | |

| punch table | mm | 100 | 125x140 | 95x155 | 95x155 | 140x160 | 200x200 | 200x200 | 245x270 | 350 | |

| Slide Surface | Fb | mm | 120 | 130 | 140 | 140 | 140 | 176 | 176 | 220 | 360 |

| Lr | mm | 120 | 140 | 150 | 150 | 170 | 210 | 210 | 270 | 480 | |

| Shank hole | Dia | mm | 30 | 30 | 40 | 40 | 40 | 42 | 42 | 50 | 60 |

| Deep | mm | 45 | 50 | 50 | 50 | 50 | 70 | 70 | 70 | 80 | |

| Depht of throat | mm | 300 | 400 | 320 | 1250 | 500 | 680 | 1250 | 700 | 500/700 | |

| Distance of both pole | mm | 160 | 185 | 180 | / | 200 | 250 | / | 300 | 680 | |

| Overall dimensions | Lr | mm | 1200 | 1300 | 1500 | 1500 | 1600 | 1750 | 3000 | 2000 | 2600 |

| Fb | mm | 600 | 730 | 820 | 820 | 900 | 1100 | 1100 | 1300 | 1800 | |

| H | mm | 1500 | 1700 | 1850 | 2100 | 2000 | 2300 | 2200 | 2500 | 3500 | |

| Motor | Power | KW | 1.1 | 1.1 | 2.2 | 2.2 | 2.2 | 4 | 4 | 5.5 | 11 |

| rpm | r/min | 1440 | 940 | 1440 | 940 | 1440 | 1440 | 1440 | 1440 | 1440 | |

| winght | kg | 650 | 800 | 1100 | 4000 | 1700 | 3200 | 6100 | 6000 | 1 | |

OUR TEAM

SHIPMENT & DELIVERY

WORKSHOP AND FACTORY