1. Products description for the Steel building ( made of welded H column ) :

Main Steel | |

Steel Beam Column | Q235B , Q345B |

Secondary Steel | |

Tie Bar | Q235B |

Purlin | C and Z purlin |

Bracing | Q235B |

Accessories | |

Surface | Painted or Hot Dip Galvanized |

Door | Rolling Up Door or Sliding Door |

Window | PVC or Aluminum Alloy |

Roof and Wall Panels | Corrugated Steel Sheet , EPS Sandwich Panel , Rock Wool Sandwich Panel , PU Sandwich Panel |

Others | |

Service | Design , Fabrication and Installation |

We can offer quotations according to customers' drawings and requirements , free design drawings and detailed installation drawings . | |

Design software : Auto CAD , PKPM , MTS , 3D3S , TArch , Tekla Structures ( X steel ) V12.0 , etc | |

Packing | main steel frame with 40 OT roof and panel load in 40 HQ Or According To Customer Requirement |

2. Who we are:

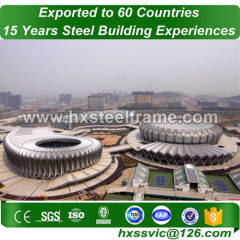

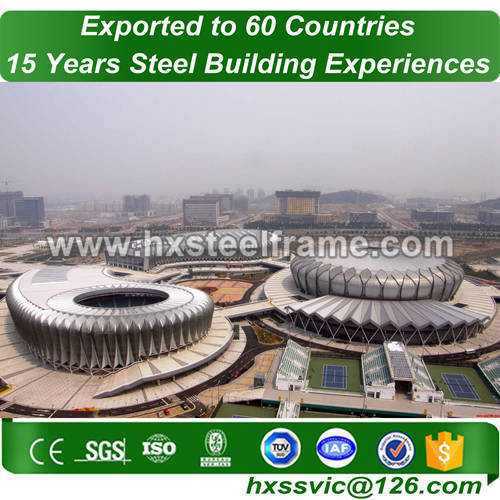

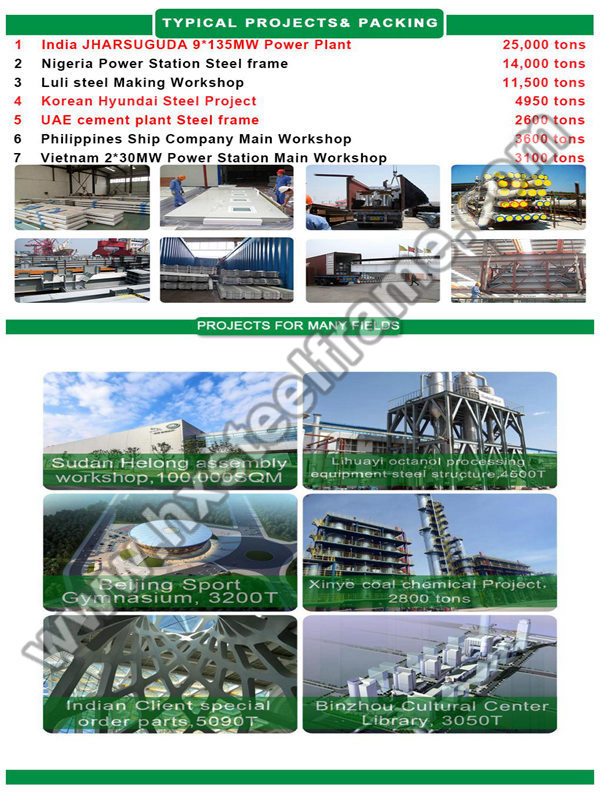

We are mainly specially steel structure construction company undertaking the design, fabrication, assembly, and after-sales service of various types of Steel building ( made of welded H column ), civil construction, heavy steel structures, stadiums, industrial workshops and warehouse building, steel structures high-rise building.

Now we have 3 heavy steel production line, six light steel production lines, 3 H-beam secondary processing lines, and advanced digital-controlled multi-head cutting machine,automatic submerged arc welding machine, assembly machine, calibrating machines, full-automatic shot blasting machines, totaling 200 equipment or more.

3. Project case- Philippines Prefabricated Cold Storage Warehouse, 2013, 2900 tons:

Main steel frame:

Steel beam & column: Q345, Welded H beam

Wind-resistant column: Q345, Welded H beam

Secondary frame:

Roof purlin: Z250*75*20*2.2

Ceiling purlin: C120*50*20*2.2

Wall purlin: C180*70*20*2

Tie bar: 102*2

Vertical & horizontal bracing: 20

Kneel-bracing: L504

Purlin bracing: Q235, 12

Sleeves tube: Q235, 32*2.5

Roof system:

Type V930 pu panel 0.5/100/0.6mm Pu panel

Wall system:

Type v930 panel 0.5/100/0.6mm Pu panel

This project is invested by the government, before the client issue the order, the client, government, and the 3rd party consulting company visited us for 4 times. Finally after compare the advantage between 6 suppliers, they choose us. The later result prove their selection are wise. We finish the project 20 days before the delivery end date, and with good quality.

4. We found international surface treatment system for the Steel building ( made of welded H column ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for Steel building ( made of welded H column ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Why I should choose your company ?

A: Firstly, we are the real factory, all range of steel structure products are manufactured on our production line. Now we already have two production base, we can guarantee our product and ensure the delivery time. We can manufacture the products which meet your special demand and we will do everything in our power to turn out the satisfaction to you. Secondly, we have professional foreign trade team with high efficiency communications and we can give you professional solutions. We will work hard and strive towards our service concept of " Zero-Defect Quality, Zero-Distance service and Zero-Complaint Service ". Thirdly, we have good business relationship with our partners and we have extends business to over thirty countries in Western Europe, Southeast Asia, Africa and South America. We will keep researching and developing, to provide more and more excellent products and perfect service to all customers.