1. Steel building ( made of frame steel ) main components description :

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

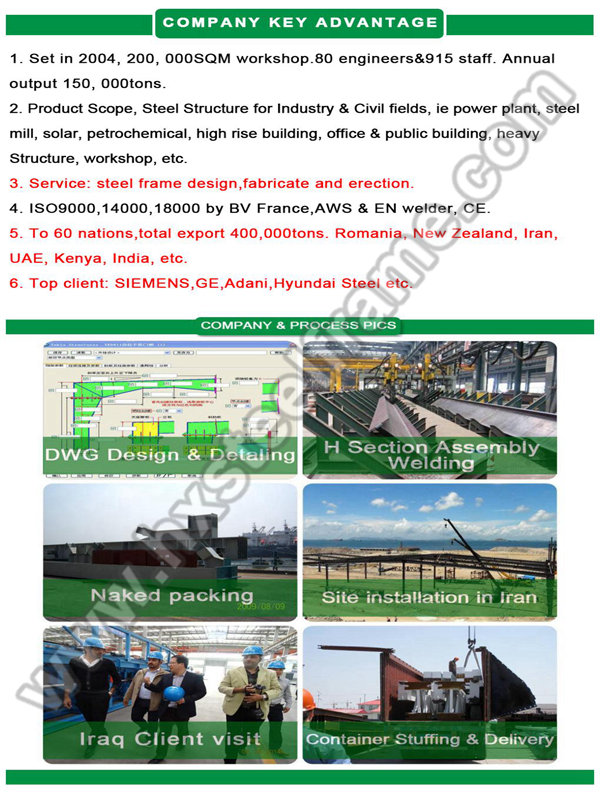

2. Who we are:

We are mainly specially steel structure construction company undertaking the design, fabrication, assembly, and after-sales service of various types of Steel building ( made of frame steel ), civil construction, heavy steel structures, stadiums, industrial workshops and warehouse building, steel structures high-rise building.

Now we have 3 heavy steel production line, six light steel production lines, 3 H-beam secondary processing lines, and advanced digital-controlled multi-head cutting machine,automatic submerged arc welding machine, assembly machine, calibrating machines, full-automatic shot blasting machines, totaling 200 equipment or more.

3. Project case- West Chuang Company Steel Structure Workshop / Light steel structure warehouse:

1) Roof: Color-coated Corrugated Steel Sheet with skylight panel

2) Wall: Color-coated Corrugated Steel Sheet

3) Main Steel Framework: Steel Column, Beam, Purlin and other supporting parts with shot blasting and painting process.

4) Material: Q345

5) Window: Plastic Steel Window

6) Door: Sliding Door plus Canopy(all are made by sandwich panel)

7) PVC Downpipe

8) Total 3000tons

4. Our Software for design and detailing of Steel building ( made of frame steel ) :

We are located in Shandong China, in response to the increasing demand for Qualified Steel structure and steel building Products on industry, commercial and residential construction.

Utilizing state of the art computer software( Staad pro V8I, PKPM, SAP2000, MIDAS, RAM Connection Standalone 10) for the designs and detailing. We provide you the most competitive design and the highest quality shop drawings, ensuring clear representation of your project requirement that enables faster and economic construction on site.

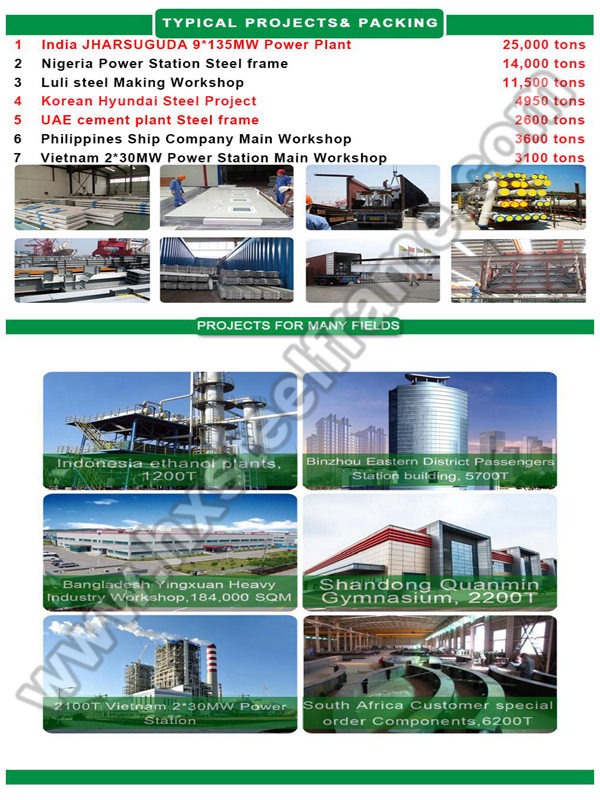

5. Packing & Delivery for Steel building ( made of frame steel ) :

For Main Components: Put steel structure components on a steel pallet and tie up the frame part together by packing strap with wood beam and cardboard, then load into container by crane or forklift

For cladding: Plastic film wrap the roof and wall corrugated single steel plate.

but for sandwich panel will load into container piece by piece

This package is to protect the goods from damage, during the transportation.

Delivery:

Load into 40/ 20GP, 40HQ, 40OT or Bulk carrier.

Delivery Time: 15 to 30 days after the receiving deposit or according to client' s requirements.

6. FAQ:

1) How to install Steel building ( made of frame steel ) ?

Reply: We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if need. if you have no work teams, we can send our professional teams to install for you.

2) Storage Life of Steel building ( made of frame steel ) ?

Reply: All steel structure frame life is more than 50 Years, all cladding sheets are about 20 Years.

3) How can you deal with deformation when welding ?

We select suitable welding method, material and sequence as specified material required.