1. Technical specs for the Steel building ( made of heavy duty structure ) :

Item name | Material characteristics | Material Grade | Surface Treatment |

Anchor bolt | Steel rod M24 , M27 | Q235B | |

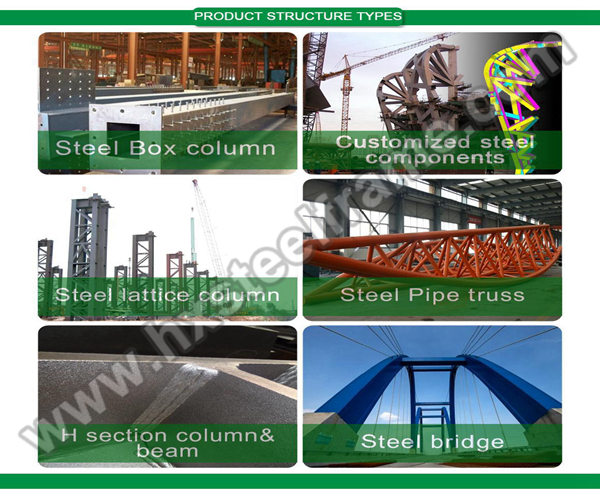

Steel Column | H shape , Box , steel pipe , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

Steel Beam | H shape , steel Truss , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

Steel Bracing | Steel rod , Steel pipe , Angle steel | Q235B , Q345B | Paint |

Steel Purlin | C or Z shape , steel purlin Thickness :1.8mm ~ 3.0mm | Q235B , Q345B | Hot dip galvanized |

External wall panel , Roof panel | Sandwich panel with EPS , Rock wool , Pu , Glass wool | Steel T = 0.426 ~ 0.8mm , insulation T=50 ~ 150mm | Alu-zinc galvanized then painted |

Door | Sliding or rolling door | Steel or Aluminum sheet , T = 1.0 ~ 1.5mm | Paint or Hot dip galvanized |

Window | alloy-Glass , Aluminium alloy - shutter | T = 1.0 ~ 2.0mm | Alloy |

Day-lighting panel | FRP , T = 1.5mm or T = 1.8mm | Coefficient of thermal expansion : 2.2 x 10 - 5 / cm | Light transmittance 85% |

Ventilator | Turbine ventilator, ventilator along a slope | Steel , stainless steel , PC | Paint , 304 |

Gutter | Galvanized Steel plate , stainless steel plate | T = 2.0mm | Paint , 304 |

Downpipe | PVC pipe , T = 0.5mm | Φ110 , 160 , 200 | |

Bolt | Ordinary , high strength | 10.9S , 4.8s | Bluing for high strength bolts |

2. Company Brief:

Founded in Shandong, we are one of the most powerful enterprises of steel building and steel structure in China.

Area of Main factory: 360,000 square meters and the 200,000 square meters' workshops.

Total number of staff: 960 persons, details are as follow:

Number of Admin Staff: 140.

Number of Marketing and Sales: 102.

Number of Architectural Designers: 58

Number of In Line QC: 38.

Number of regular workers for production and installation of Steel building ( made of heavy duty structure ) : 600

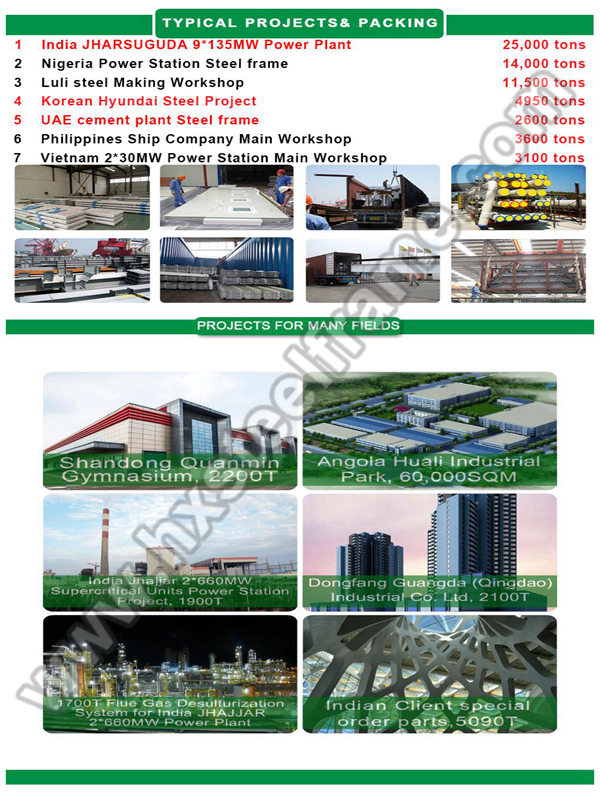

We have the experience to do the big projects with the top rank construction company in the world, we are always showing our best service and professionalism, and we have exported the steel structure buildings to more than 110 countries.

3. Project case- South Africa Light Pre-engineered Building, 7000SQM, 2011:

South Africa workshop project

usage: steel pipe production workshop

length 252M X width 27.5M X height 11M, with a crane of 30 ton, the crane sling height is 7M. The workshop adopt Frame bent structure, lattice form column. Roof and wall surface is single steel sheet, no heat insulation, the bottom of wall has brick wall that 800 mm height and aluminum windows that 1.8m height, skylight sheet on roof for lighting.

Client issue the order to us within 1 week after visit our factory, our hardware and ISO management system leave deep impression to them. Now, we have finished more than 6 orders for this client.

4. We are extremely powerful in supplying Complex Steel Structures:

We are good at flexible and versatile production for the fabrication of complex and heavy steel pieces and structures, thanks to:

1) Advanced engineering

2) Proven fabrication processes adapted for carrying out these types of unique products

3) Know-how and long-standing experience in fabrication of complex steel built-ups

4) Lifting capacity of 200 tons for handling fabrication work of heavy steel built-ups

5) Large working areas to carry out assembly work of oversized steel built-ups

6) Important fabrication capacity for large scale projects

The weight and size of these types of products or the combination of these factors can be challenging, especially in terms of handling activities in the plant and transport. As such, certain of the steel built-up components weighing over 60 tons have to be shipped in sections to the construction sites where they will be installed.

5. Packaging & Delivery for Steel building ( made of heavy duty structure ) :

Packaging Details

steel structure factory packaging:

1) steel structure: steel frame or pallet packing

2) panel: plastic film packing

3) Bolts: steel box packing

4) loaded into 40' HQ

Delivery Time

Shipping depended on order quantity or to the customer' s requirements

6. FAQ:

1) How about the derust grade of your Steel building ( made of heavy duty structure ) ?

Reply: Ball blasting Sa2.5 on main steel structure or by Galvanized frame;

manual derust St2.5 on secondary steel structure.

2) What kind of panel used for the roof and wall ?

Reply: Color corrugated steel sheet and sandwich panel could be used. Sandwich panel performs well on the heat insulation, sound insulation. Common sandwich materials are EPS, glass wool and PU sandwich panels.

3) Are Steel building ( made of heavy duty structure ) expensive ?

Answer: The steel structure of our company is economic. Its technology and materials used decreases waste expenses such as wood, decorative stone, brick etc. All the material including the steel frames, wall body and roof for installation are prefabricated during the production process, therefore the labor costs for installation is decreased.