SPC Stone Floor Production Extrude Line

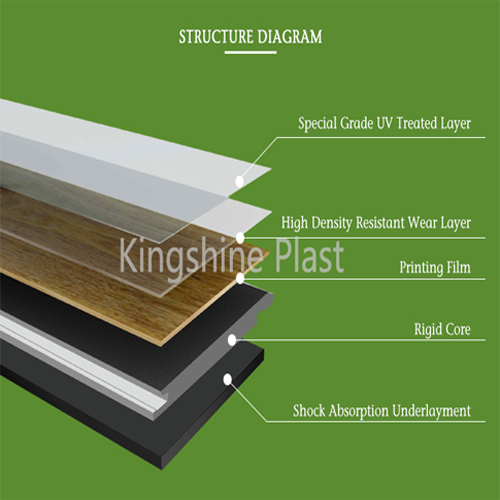

1. Elasticity: one-step SPC floor, different from the stone, tiles and other hard materials, imitation stone and wooden surface floor gives a more comfortable experience.

2. Taking into consideration of the health and anti-skid, SPC floor has a unique anti-skid ability, while ensuring adequate resistance to dirt, easy to clean.

3. Anti-mildew insects: SPC floor, wear durable, good shrinkage stability; surface is pure PVC wear layer, high wear resistance. And wood flooring is easy to deformation and with high risk of raw insects

4. Non-toxic: the latest environmentally friendly technology, low cost, high stability, zero formaldehyde.

Factory of domestic customer

NO. | ITEM | PARAMETERS |

1 | EXTRUDER | 92/188 OR 110/220 CONICAL TWIN SCREW |

2 | WIDTH | 980MM |

3 | THICKNESS | 2-6MM |

4 | CAPACITY | 750KG/HR--1250KG/H |

Famous electrical configuration:

1. Main motor frequency controller: ABB

2. Temperature controller: Siemens PLC

3. AC controller: SIMENS

4. Thermal overload relay: SCHNEIDER

Factory of abroad customer

Work Flow

Process 1 : Mixture

According to the ratio of raw materials for automatiic weighing, high-speed

mixer hot mix (thermal mixing temperature: 125 ℃, role is the mixing of various

materials, eliminate the moisture in the material) - > enter cold mix (material cool

down to prevent caking and discoloration, cold mix temperature: 55 ℃).- by cooling

mixing of materials;

Process 2: Extrusion

Join the twin screw extruder, heated extrusion - into the sheet forming,

extrusion molding pieces.After four roll calender, base material to decide

to stick color film, thick stick wear-resisting layer - cooling - cutting;

Process 3: UV tempering

Surface UV - tempered, tempering hot water temperature: 80 ~ 120 ℃;

The cold water temperature: 10 ℃)

Process 4: Self-finished Product inspection

Cutting, notching, trimming, chamfering to inspection, packaging.

Service

Pre-sale service

-To provide information and market research.

-To provide consultation,to provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-Take our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Packing

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.