Applicable documents:

API Spec. 7-1: specification of rotary drilling equipment;

ISO 10424-1: drilling and production equipment, part 1: specification of rotary drill stem elements;

ASTM A370: mechanical testing of steel products;

ASTM E587: standard practice for ultrasonic angle beam contact testing;

ASTM E709: standard practice for magnetic particle testing;

ASTM E23: standard methods for notched bar impact testing of metallic materials.

Non-destructive examination of forgings:

General

All standard steel forgings shall be examined for both surface breaking and totally enclosed internal defects. Non-destructive examination shall take place after the completion of all heat treatment.

Surface Defects

Outside surface breaking defects:

The outside surface of each standard steel bar or tube shall be inspected for defects. The preferred methods are either the Ultrasonic (UT) or Magnetic Particle (MT) methods. As an option, other methods (such as eddy current) may be used, providing it can be demonstrated that the system and procedure are capable of detecting indications described in Table A.16.

Inside surface breaking defects:

The inside surface of each tube shall be inspected for defects by the ultrasonic (UT) angle-beam (shear wave) method. This requirement applies only to materials that are identifiable as tubes before heat treatment. Materials that are heat-treated are not considered tubes, for inspection purposes.

Delivery Conditions: forged piece, rough machined (Q&T), finish machined.

Specifications:

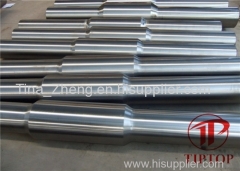

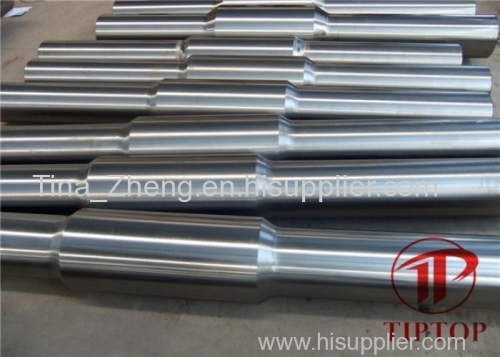

-Type: Integral straight or spiral blade stabilizer

-Material: AISI 4145H MOD or Non-magnetic steel

-OD: 6''~28''

-Length: max 9m

-Standard: API SPEC 7-1( or as your requested technical requirement)

-Process: EAF+LF/VD+(ESR)+Forged + Heat treatment + Rough machining

-Surface finishing: Black, Peel, Turned, Polished

-Delivery condition: Hot forged, Heat treatment(Q+T), Rough machining

-Blade: normal 3~4 blades