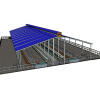

As a classification of mobile housing products, the Agricultural prefab house has been widely used in livestock and poultry sheds, barns, grain, animal feed and other agricultural materials storage. Due to the product mainly steel square tube and C section steel purlin as the skeleton of the product so there are certain limitations in the span and height of the single. But it also has the following advantages:

In factory design and production, the main structure is connected by bolts, standardized production, accurate component size, a small error.

Mechanized processing, component standards with interchangeability.

The material quality is light, easy to assemble and disassemble.

The manufacturing and installation cycle is short, and the number of rooms can be reduced or increased without changing any original materials during the turnover according to the needs of customers in the process of disassembly, which is convenient for transportation.

Beautiful and durable, the product life of more than 15 years, according to the cycle of maintenance and replacement, can extend the product life of more than 10 years. One-time investment, high reuse value, low comprehensive use cost.

Product Parameters of Prefab Agricultural Buildings, Prefab Farm Buildings

Prefab T Type house Agricultural Buildings Cow shed Prefabricated Barn Horse Stable Technical Specification

No.+A2:D29 | Sort | Name | Specification |

1 | Product Type | Degree of Standardization | custom-made product, design and manufacture according to clients requirement |

2 | Size | Length (m): | No limited, increase expansion joint when length more than 200m. |

3 | Width(m): | single span should be less than 12m, an arbitrary width could make by union spans | |

4 | Heigth(m): | single floor≤5m, two or three floors, average height ≤4m | |

5 | Roof slope: | slope is 1:10~1:5 | |

6 | Standard equipment | Ground channel | Galvanized steel panle compression, thickness is 0.8mm |

7 | Post | Inside post is steel square pipe, material is Q235, components surface make antirust process, and decorate with color steel compression parts. | |

8 | Roof beam | roof truss consist of thin sharpe steel by welding, component surface make antirust process | |

9 | Purlin | C or Z section steel, size from C120~C320, Z100~Z200 | |

10 | Wall beam | wall beam is Ctype steel or square pipe, material is Q235,component surface make antirust process | |

11 | Floor | made of floor master beam, secondary beam and floor surface plate(plywood) | |

12 | Wall & roof panel | EPS, rock cotton, fiber glass, PU Sandwich panels/ or steel sheet | |

13 | door | Sliding door or rolling door | |

14 | window | PVC sliding window, with steel screen. | |

15 | Electrical accessories | Supply plan, design and construction according to relevant national norms(220V,50Hz, with lamp, switches and multi-function sockets.) | |

16 | Water plumbing accessories | Supply plan, design and construction according to relevant national norms | |

17 | Bracing | Steel angle, steel pipe, steel round. | |

18 | Gutter | Steel sheet or galvanized steel sheet | |

19 | Rainspout | PVC pipe | |

20 | Accessories | Anchor bolt, high strengthen bolt, normal bolt, skylight panel, ventilators, etc. | |

21 | Design technical data | Roof dead load | 0.3KN/sqm |

22 | Roof live load | 0.5KN/sqm | |

23 | Floor dead load | 0.5KN/sqm | |

24 | Floor live load | 2KN/sqm | |

25 | Wind load | 12degree,120km/h(strengthen the steel frame when the wind is bigger than this data) | |

26 | Earthquake resistant intensity | 8 degree | |

27 | Used for temperature | Celsius: from -25 to+50 (change the design when the temperature is lower than Celsius -25) | |

28 | Installation | Installation tools | electric drill, electric hammer, spanner, screwdriver, pulling rivet etc, house installation need electric power. |

29 | Installation efficiency | Four skilled labor one day can erect 40m2's house body | |

30 | Transport | container | each 40ft container could load 130~150Sqm house body material |

Advantages of prefabricated agricultural buildings, prefabricated farm buildings

Factory design and production, the main structure is connected by bolts, standardized production, accurate component size, small error

Mechanized processing, component standards with interchangeability

The material quality is light, easy to assemble and disassemble.

The manufacturing and installation cycle is short, and the number of rooms can be reduced or increased without changing any original materials during the turnover according to the needs of customers in the process of disassembly, which is convenient for transportation

Beautiful and durable, the product life of more than 15 years, according to the cycle of maintenance and replacement, can extend the product life of more than 10 years. One-time investment, high reuse value, low comprehensive use cost

Zhongtai company is a professional metal frame buildings manufacturer, the flat pack container house is our main product, we can provide daily production capacity of 200 sets, fully meet your high-end, middle and low-end product needs, you are welcome to contact our company to discuss business.