Product introduction of anti-stripping high alumina brick

High Anti-stripping alumina brick are made of raw materials that are inconsistent with the expansion coefficient of high-alumina bauxite. The thermal shock stability of the product enhances the high temperature and chemical corrosion resistance. The service life of Anti-stripping high alumina brick is more than 3 times that of traditional high-alumina bricks.

Application of high Anti-stripping alumina brick

high Anti-stripping alumina bricks are mainly used in the transition zone of cement rotary kiln, decomposition furnace, tertiary air duct, and other thermal equipment requiring thermal shock.

Product parameters of Anti-stripping high alumina brick

Model | GKBL-70 | KBL-70 |

Al2O3(%) | ≥70 | ≥70 |

ZrO2(%) | ≥6 | |

Fe2O3(%) | ≤1.5 | ≤1.5 |

Bulk density(g/cm³) | ≥2.55 | ≥2.55 |

Apparent porosity(%) | ≤22 | ≤20 |

Compressive strength(Mpa) | ≥60 | ≥60 |

Load softening start temperature(℃) | ≥1470 | ≥1470 |

Thermal shock stability, times [1100℃, water cooling] | ≥20 | ≥15 |

Production process of high Anti-stripping alumina brick

High Anti-stripping alumina bricks are high-alumina bricks with anti-stripping properties produced by adding ZrO2 (zirconium dioxide) or other materials based on high-alumina clinker. The production process of anti-stripping high-alumina bricks is relatively complex, and the production is roughly divided into four stages: preparing the required raw materials—extrusion molding—high temperature forging—cooling and packaging.

Advantages of high Anti-stripping alumina brick

1. Anti-peeling high-alumina bricks have strong volume stability at high temperature

2. The product has a high softening temperature under load and does not shrink in volume

3. Anti-stripping high-alumina bricks have excellent thermal shock resistance

4. Anti-stripping high-alumina bricks are resistant to abrasion and do not produce structural spalling

5. High chemical resistance, no cracking

Company Profile

Zhengzhou Zhenjin refractory material CO., Ltd. was established in 1985 and is located in Xinmi City, Henan Province, a refractory production base in China. It covers an area of about 70,000 square meters. It is a company integrating R&D, production, sales, international trade and technical services. An integrated manufacturing enterprise. The company is committed to the provision, construction and installation of refractory products in the cement industry, glass industry, building materials industry, non-ferrous smelting and metallurgical industries and other personalized services.

Zhengzhou Zhenjin refractory material CO., Ltd. has long been focusing on the research and development and production of high-quality refractories. At the same time, it has also developed and produced magnesia-aluminum spinel bricks, magnesia-iron tip Refractory bricks such as spar bricks have successively created a number of safe use records in the cement industry. The company's products are exported to Greece, South Korea, Japan, Canada, Chile, Mongolia, Cambodia and other international markets. The products have won the trust and praise of users for their stable performance, excellent quality and exquisite craftsmanship. Our company has always been adhering to the business policy of "customer interests first", aiming at international refractory production standards, integrating resources, and further enhancing the company's core competitiveness in the field of refractory manufacturing.

Packing & Shipping

1,magnesium alumina spinel brick will be packed by Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film or according to customer's requirements.

2,We will deliver the goods on time, with guaranteed quality and quantity, in full accordance with the contract and customer requirements.

3,With superb technology, excellent product quality and service, Zhenjin has obtained your cooperation and support. Continuing to provide quality services is our unremitting pursuit.

Our Service

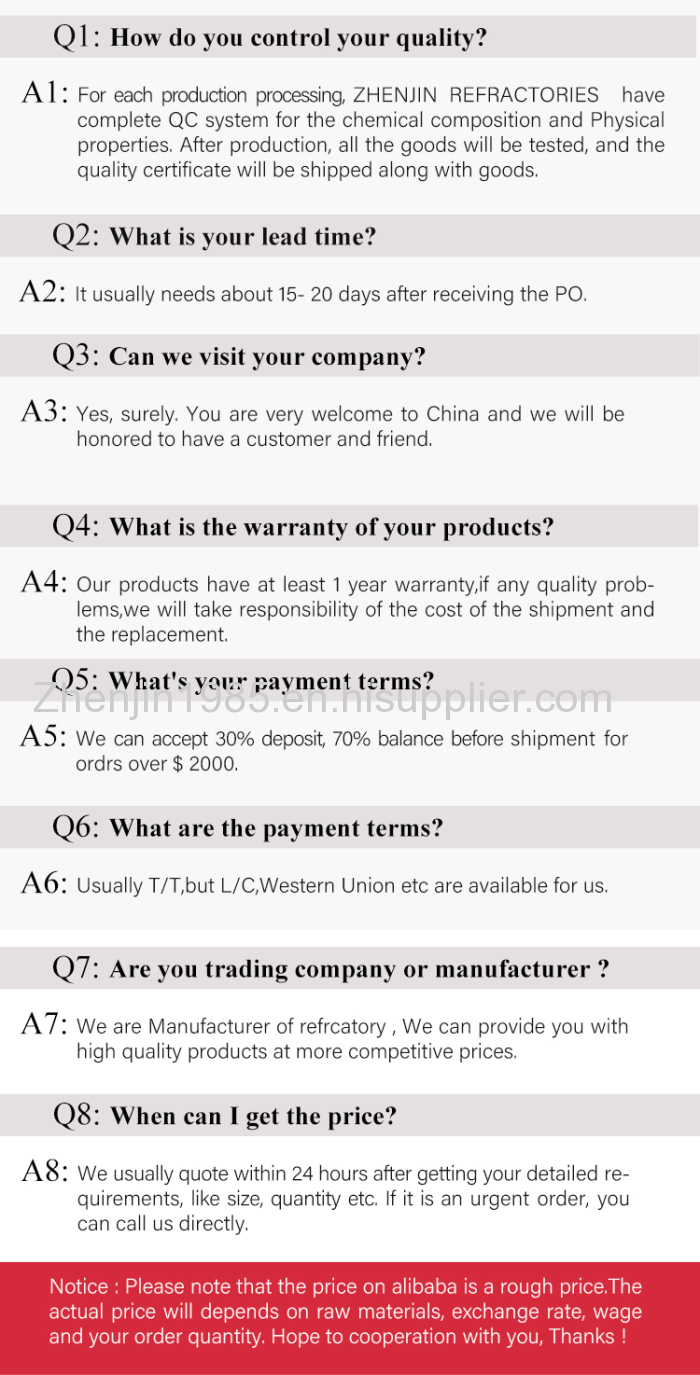

FAQ