Gear manufacturing is the process of making gears out of different types of material, including steels, alloys, plastics, and other metals. Many different products and industries make use of gears. Small gears can be used in small electronics, medical devices, tool kits, and exercise equipment. Large gears are often used in heavy, industrial machinery, cars, airplanes, and more. As these components are needed all across the world, gear manufacturing is a large industry.There are many different processes in gear making. The first process is the gear forming process. This is where the shape of the gear is decided and a mold may be created to make many gears of the same size and shape. There are different ways of forming a gear which include plastic injection molding, forging, casting, roll forming, and more. Many times an assembly line is used to mass produce various gears for different uses in machinery or vehicles. A gear blank, which is an uncut wheel, will be used as the basic form for the gear.

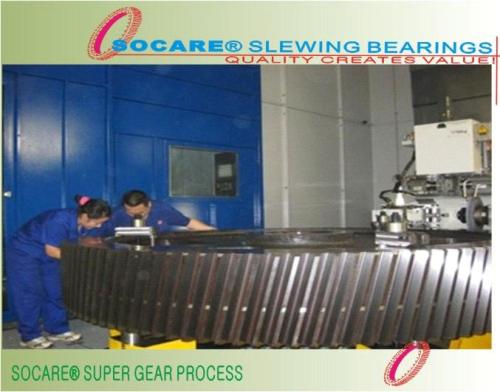

Another step in the gear manufacturing process is cutting the gear. This involves changing the shape of the gear so that it is suited for its intended use. The gear can be cut in many different ways, including through broaching, hobbing, shaping, lapping, and milling. Most ways of cutting gears involve using machinery to get the precise shape and size required, and more than one process can be used in the formation of a single gear. A gear may need to be cut down to size and then carefully sanded in order to attain the precise shape needed.The last step in gear manufacturing is typically the finishing process. This is where the gear is polished. Finishing techniques can include grinding, shaving, and honing. This is what makes the gear unique and able to be used in whatever product it is designed for. For smaller gears, this step may take longer, as it will require precision guidance to finish the gear correctly.Clients who need a large quantity of gears for making their own products can contact SOCARE company in order to place special, custom orders or to place bulk orders. Working closely with one gear manufacturer can make it easier to have access to the type of gears that a company might need to keep their own warehouses working at maximum capacity. Some common industries that are likely to work closely with a gear manufacturing company include those in the aerospace, automotive, mechanical, and medical fields.

Home >

Machinery & Industrial Supplies

>

Power Transmission Equipment

>

Gear, Gearbox, Speed Reducer

>

High accuracy Gear Manufaturing

High accuracy Gear Manufaturing

| Price: | 200.0~8000.0 USD |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

Trade on HiSupplier, Worry Free Guarantee

•Trading safety, secure your money, lower the risk, protect both buyers and suppliers

•HiSupplier is a Chinese multinational company in U.S, it helps to coordination and order landing.

- Product Details

- Company Profile

- Product Reviews

Basic Info.

- Processing: Hobbing

- Shape: Cylindrical Gear

- Standard or Nonstandard: Nonstandard

- Material: Steel

- Tooth Profile: Helical Gear

- Brand Name: SOCARE

- Place of Origin: Henan

- Min.Order: 10 Piece/Pieces

- Means of Transport: Ocean, Air

Supply Capacity

- Production Capacity: 100 pcs per month

- Packing:Standard exporting box suit for long-term marine transit

- Delivery Date: 25 working days

Didn't find what you're looking for?

Post Buying Lead or

contact our customer service specialist for help!