With the development of gypsum industry, there is a large demand for quantity and high quality of gypsum powder. Therefore, the high level of gypsum powder production technology is required. In the process of gypsum powder production, drying and dewatering is the key link, which is also the most difficult one to control. In order to solve this problem, we develop a new type of drying and dewatering equipment---ebullience calciner, which is produced based on the exploring of the gypsum production filed. Following is the brief introduction of the gypsum production technology and ebullience calciner working principle.

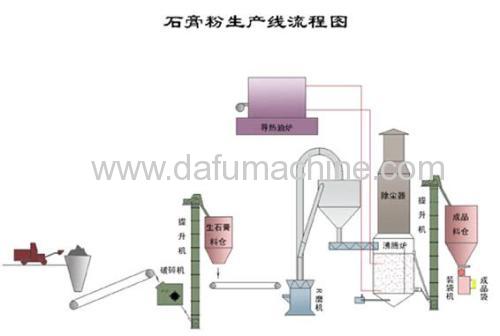

1.The technology of gypsum powder production:

The main composition of gypsum is hydrate gypsumCaSO4.2H2O. however, the gypsum powder used in practical productionsuch as the gypsum powder for gypsum board, for mould, for plasteringis to dry and dewater the dehydrate gypsum which of certain fineness, reduce the content of crystallization water in it, so the standard of crystallization of gypsum powder can qualify all kinds of gypsum powder, because it can change into plaster of paris. Plaster of paris can re-integrated with water when it is applied into production, and it can be processed into new type building materials with a high intensity, such as gypsum board, gypsum block, act.

Existing gypsum powder drying technologies are frying boiler and rotary kiln plant . It means that put the gypsum powder into the frying boiler and coil pipe, and before the gypsum powder was put, the heat produced by the burning of the medium in kiln furnace was send into the frying boiler and rotary kiln plant by fan. In this way, the quality of gypsum powder is difficult to guarantee, because the content of crystallization water is uneven.

.jpg)