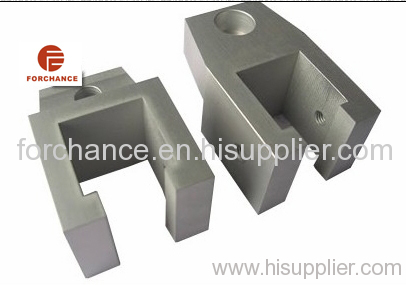

High-speed production - Die casting provides complex shapes within closer tolerances than many other mass production processes. Little or no machining is required and thousands of identical castings can be produced before additional tooling is required.

Dimensional accuracy and stability - Die casting produces parts that are durable and dimensionally stable, while maintaining close tolerances. They are also heat resistant.

Strength and weight - Die cast parts are stronger than plastic injection moldings having the same dimensions. Thin wall castings are stronger and lighter than those possible with other casting methods. Plus, because die castings do not consist of separate parts welded or fastened together, the strength is that of the alloy rather than the joining process.

Multiple finishing techniques - Die cast parts can be produced with smooth or textured surfaces, and they are easily plated or finished with a minimum of surface preparation.

Simplified Assembly - Die castings provide integral fastening elements, such as bosses and studs. Holes can be cored and made to tap drill sizes, or external threads can be cast.

The basic die casting process consists of injecting molten metal under high pressure into a steel mold called a die. Die casting machines are typically rated in clamping tons equal to the amount of pressure they can exert on the die. Machine sizes range from 400 tons to 4000 tons. Regardless of their size, the only fundamental difference in die casting machines is the method used to inject molten metal into a die. The two methods are hot chamber or cold chamber. A complete die casting cycle can vary from less than one second for small components weighing less than an ounce, to two-to-three minutes for a casting of several pounds, making die casting the fastest technique available for producing precise non-ferrous metal parts.

.jpg)

.jpg)