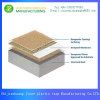

The thermoplastic polyolefin(TPO)waterproof membrane is a new type of polymer waterproof materials,which was developed firstly in the USA in the last 90S century. Through the advanced polymerization, the material use TPO resin as the base, which combine ethylene-propylene rubber's weather resistance with polyolefin's thermal weld ability. The TPO waterproof membrane consists of two layers of thermoplastic polyolefin and one layer of polyester fiber reinforcing in the middle, just as sandwich structure. The thermoplastic polyolefin material which without plasticizes offers the abilities of weather resistance and thermal weld. The polyester fiber strengthened the membrane's breaking strength, tear strength and resistance to puncture. So, it can be used for the single layer of waterproofing roof. Meanwhile, it is a typical green product due to its some features, such as, light color of surface reflected sunshine, including no chlorine, total recycling and so on. So, the material has been "NEW FAVOR" in the market of the USA and Europe, and welcomed by the customers and the construction companies.

Advantages:

1, good flexibility, high elongation, high tensile strength

2, durability, chemical corrosion resistance

3, sunlight reflection

4, resistance to static, dynamic puncture

5, avoid bacterium,

6, excellent weld ability

1, good flexibility, high elongation, high tensile strength

2, durability, chemical corrosion resistance

3, sunlight reflection

4, resistance to static, dynamic puncture

5, avoid bacterium,

6, excellent weld ability

Specifications:

a Resistance to static loading only the pressure membrane Roofing.

b Single membrane roofing using the product of artificial climate accelerated talent time 2500h

b Single membrane roofing using the product of artificial climate accelerated talent time 2500h

Application:

TPO products can be widely used in various industrial and civil engineering waterproofing roof, especially for steel and reinforced concrete structure of the roof waterproof.

TPO products can be widely used in various industrial and civil engineering waterproofing roof, especially for steel and reinforced concrete structure of the roof waterproof.

Packing and shipping:

1. membrane curled cylindrical, external plastic or film bag packaging.

2. membrane in transport and storage, should pay attention not to damage the packaging, placed in ventilated, dry place, storage should not exceed the flat stack of five sheets of high volume level. Pile should be placed on level ground in dry, avoid direct sunlight, prohibit acids, alkalis, oils and organic solvents and other contacts, and isolation heat.

3. in the normal transportation, storage conditions, storage period from the

date of production for one year.

Construction Method:

TPO waterproofing membrane can be mechanical fixation of the construction and bonding method.

Mechanical fixation:

1. in accordance with the width of the sheet construction to be fixed spacing 30cm

2. adjacent overlapping coil nails and pads should be more than the fixed position of about 5-6cm

3. seams heat welded construction using

Bonding:

Adhesive used to bond together with the primary coil.

Construction Method:

TPO waterproofing membrane can be mechanical fixation of the construction and bonding method.

Mechanical fixation:

1. in accordance with the width of the sheet construction to be fixed spacing 30cm

2. adjacent overlapping coil nails and pads should be more than the fixed position of about 5-6cm

3. seams heat welded construction using

Bonding:

Adhesive used to bond together with the primary coil.