Permanent Magnet Materials

Permanent magnets are used in the following major groups: acoustic transducers, motors and generators, magneto mechanical devices, and magnetic field and imaging systems. You will find permanent magnets in many products, such as televisions, telephones, computers, audio systems and automobiles.

The permanent magnet family consists, in general terms, of non-rare earth permanent magnets and rare earth magnets. The non-rare earth magnets include Alnico (Aluminum-Nickel-Cobalt) magnets and Ceramic (Strontium and Barium Ferrite) magnets. Rare earth magnets include Sm-Co (Samarium-Cobalt) magnets and NdFeB (Neodymium-Iron-Boron) magnets.

Although non-rare earth magnets are used in the majority of these applications due to their economic cost, rare earth permanent magnets have many distinguishing characteristics, such as a large Maximum Energy product, (one performance index for permanent magnets). Dozens of magnetic materials which contain rare earth have been developed recently. Two major families of rare earth permanent magnets, SmCo magnets and NdFeB magnets, have been widely used in a variety of applications. Each family has its own advantages and disadvantages.

[Back to the beginning of this page]

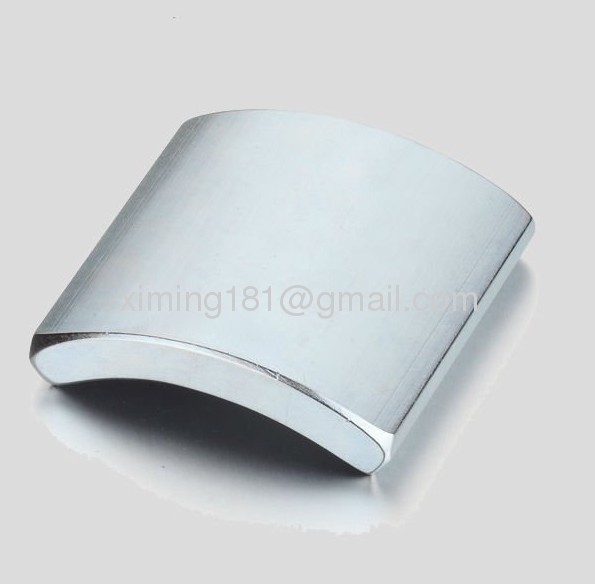

(BH)max, than Sm-Co magnets. (BH) max of NdFeB can easily reach 30 MGOe and even goes up to 48 MGOe. NdFeB magnets can replace Sm-Co magnets in most cases, especially where operating temperature is less than 80 degrees Centigrade. The temperature stability of NdFeB is not as good as Sm-Co magnets. Magnetic performance of NdFeB magnets will deteriorate rapidly above about 180 degrees Centigrade. Compared to SmCo magnets, the corrosion and oxidation resistance of NdFeB is relatively low. Sintered NdFeB permanent magnets are made with several steps. At first, a NdFeB alloy is formulated based on the properties of final permanent magnets supposed to reach. The alloy is produced in a vacuum furnace. Then the alloy is crushed into a powder form. Sintered NdFeB permanent magnets are formed by powder metallurgical process. These magnets can be die pressed or isostatically pressed. During the pressing process, magnetic fields are applied with assistance of specially designed fixture to align magnetic "domains" and optimize the magnetic performance of these magnets. Then pressed magnets are placed into a furnace under protective atmosphere for sintering. After sintering the magnet shape is rough, and need to be machined and ground to achieve desired shape and size. A surface coating is usually applied on NdFeB magnets. Zinc or nickel coating is common used as a protective layer. Other materials such as cadmium chromate, aluminum chromate, tin or polymer (epoxy) are also used for this purpose. Both NdFeB and Sm-Co magnets can be made either in sintered or polymer-bonded magnets. The polymer (such as epoxy)-bonded magnets can be produced with close tolerances off tool, with little or no finishing required. Stamford Magnets supplies polymer-bonded NdFeB permanent magnets made by both compression moulding and injection moulding. The sintered magnets usually require some finishing operations in order to hold close mechanical tolerances. The sintered magnets, however, provide better magnetic properties than bonded magnets.