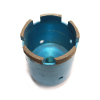

This series product is a PDC core bit that breaks formation rock by scriping action and applies high-quality and standard dimension PDC cutters.The special technique of advanced half exposing welding cutter makes firm cutter-fixing,more sthength impact resistance.Designing with gauge protection tooth prolong the bit working life.Using PDC core bit with reasonable drilling technique parameter may gain the highest economic benefits.

These Diamond Bits use polycrystalline diamond compact (PDC) cutters to shear rock with a continuous scraping motion

1 Cutting structure is force balanced and bit blade is asymmetrically designed so that the coal on bit is balanced that resulting better stability of the bit.

2 Main cutter are high performance PDC cutters to insure service life of the bit while imporving ROP.

3 Cutter exposure is optimized to insure the bit can achieve higher ROP is soft to medium formations

4 Shock absorbers are desinged to make the bit capable of drilling through formations with hard strigers.

5 Hydroulic systerm of the bit is optimized using dynamic flow patlern simulation technology to enhance cleaning and cooling effects of the bit to effectively prevent bit from balling.

Size avaliable

From 1.8 inch (45mm) to 26 inches (660mm)

Note: sizes and types that are not shown above can be customized according to specific drilling requirements

Contact: Sindy Feng