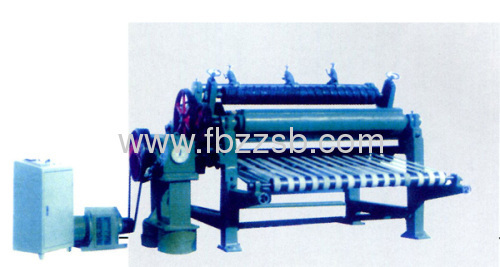

Brief introduction of the structure

Work part: compose of upper circular knife, circular knife below, feeding roll, free-swinging knife, bottom plate, paper carrying roll, canvas roller and so on.

The control motor and paper car speed cut directly on the same time. Put the paper roll that from dryer cylinder the on the unreeling stand and make it bundle in 1-8. In the meantime bring the paper roll into feeding roll to cut only once.

Slitting machine mainly compose of three upper circular knife and three circular knife below. Longitudinal cutting circular knife can adjust different distance along the axial with the aim of cutting into different specifications of the paper and take the useless paper edge. The paper that after the longitudinal cutting is all put into the paper feeder device. The paper feeding roller is drive roller to drawing paper, its rotating speed determines the working speed of the paper cutting machine. Air roll draw support from the elastic force made by the spring above sliding bearing on the both ends. In order that the air roll press paper tightly on the surface of the feeding roll, so that paper and the surface of feeding roll have no relative sliding. The elastic force of spring can be adjusted by adjusting handle. The surface of air roll is made of rubber material, and processes into the half spiral on the left and right, in order to make paper web get flattening.

1.The upper circular knife of longitudinal cutter and the cutting edge of the circular knife on the bottom must align, there shall not have a skewed vibration phenomenon. Its adjustment of upper and lower circular knife blade must based on every single paper is 52g/m and its longitudinal cutting edge is smooth.

2.The rotating knife of transverse cutting paper should be consistent with its knife edge of lower knife. The adjustment of its blade gap shall be based on turn knife roll by hand and cut the 52g/m paper gently. Before use the paper cutter, you should try it first.

3.Adjust longitudinal cutting device: firstly, adjust the lower circular knife to the optimum place. When move it, you should loose the fastening hexagonal nuts, use your hand or wooden hammer to make a axial movement. If it needs to change round bottom blade, you must take the round bottom blade out of the paper cutting machine, and then put it on the platform, until it is out of the taper pin which is used for fasten the blade, you can get the round bottom blade.

4.Adjust transverse cutting device: firstly, loose the topper cutter's screw; secondly, loose the nuts and the fastening nut on the bottom cutter seat, then turn the adjustable bolt, so the long bar on the bottom cutter seat is directed at the knife's angle on both side of the rotating knife roller, after that tighten the fastening nut and the nuts on the fixed blade; finally, use the top screw knife to adjust the waviness of the blade edge until it is qualified, and then fasten the nuts.

5.If double paper cutting wants to cut any specifications of length between 300-1800, it should keep the speed of feeding roll and alter the different speed of the rotating knife roller(jilt knife roller) to achieve. Turn the adjusting handle on the P type non-polar transmission, when it moves clockwise, the length of paper will be shorter and shorter; when it moves anticlockwise, the length of paper will become longer and longer, through this way, you can adjust the length to meet your needs. Continuously variable transmission only can adjust the hand wheel when it is starting up; it is strictly forbidden to adjust the hand wheel when it is out of work, so as to avoid make the chain bad. If it is necessary to adjust the hand wheel, you should turn the input shaft of transmission first, and then adjust the hand wheel.

6.During the procedure of cutting paper, if you find there are some mistake about the specification of the paper between the size, please see the instruction book of the continuously variable transmission. And open the roof cover of the continuously variable transmission, then fasten the chain in the box.

3.Adjust longitudinal cutting device: firstly, adjust the lower circular knife to the optimum place. When move it, you should loose the fastening hexagonal nuts, use your hand or wooden hammer to make a axial movement. If it needs to change round bottom blade, you must take the round bottom blade out of the paper cutting machine, and then put it on the platform, until it is out of the taper pin which is used for fasten the blade, you can get the round bottom blade.

4.Adjust transverse cutting device: firstly, loose the topper cutter's screw; secondly, loose the nuts and the fastening nut on the bottom cutter seat, then turn the adjustable bolt, so the long bar on the bottom cutter seat is directed at the knife's angle on both side of the rotating knife roller, after that tighten the fastening nut and the nuts on the fixed blade; finally, use the top screw knife to adjust the waviness of the blade edge until it is qualified, and then fasten the nuts.

5.If double paper cutting wants to cut any specifications of length between 300-1800, it should keep the speed of feeding roll and alter the different speed of the rotating knife roller(jilt knife roller) to achieve. Turn the adjusting handle on the P type non-polar transmission, when it moves clockwise, the length of paper will be shorter and shorter; when it moves anticlockwise, the length of paper will become longer and longer, through this way, you can adjust the length to meet your needs. Continuously variable transmission only can adjust the hand wheel when it is starting up; it is strictly forbidden to adjust the hand wheel when it is out of work, so as to avoid make the chain bad. If it is necessary to adjust the hand wheel, you should turn the input shaft of transmission first, and then adjust the hand wheel.

6.During the procedure of cutting paper, if you find there are some mistake about the specification of the paper between the size, please see the instruction book of the continuously variable transmission. And open the roof cover of the continuously variable transmission, then fasten the chain in the box.