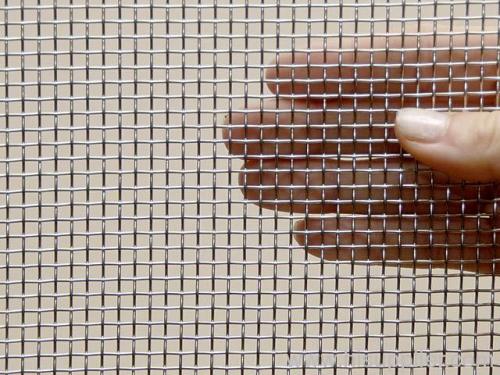

904L Stainless Steel Wire/Screen

904L is a non-stabilized low carbon high alloy austenitic stainless steel. The addition of copper to this grade gives it greatly improved resistance to strong reducing acids, particularly sulphuric acid. It is also highly resistant to chloride attack - pitting / crevice corrosion and stress corrosion cracking.

This grade is non-magnetic in all conditions and has excellent weldability and formability. The austenitic structure also gives this grade excellent toughness, even down to cryogenic temperatures.

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

Grade specifications for 904L grade stainless steels.

Grade | UNS No | Old British | Euronorm | Swedish SS | ||

BS | En | No | Name | |||

904L | N08904 | 904S13 | - | 1.4539 | X1NiCrMoCuN25-20-5 | 2562 |

Composition ranges for 904L grade of stainless steels.

Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | |

904L | min. | - | - | - | - | - | 19.0 | 4.0 | 23.0 | 1.0 |

max. | 0.020 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.0 | 28.0 | 2.0 | |

Mechanical properties of 904L grade stainless steels.

Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

Rockwell B (HR B) | Brinell (HB) | ||||

904L | 490 | 220 | 35 | 70-90 typical | - |

Rockwell Hardness value range is typical only; other values are specified limits. | |||||

Corrosion Resistance

(1)In most environments 904L has a corrosion performance intermediate between the standard austenitic grade 316L and the very highly alloyed 6% molybdenum and similar "super austenitic" grades.

(2)In aggressive nitric acid 904L has less resistance than molybdenum-free grades such as 304L and 310L.

(3)For maximum stress corrosion cracking resistance in critical environments the steel should be solution treated after cold work.

Heat Resistance

Good resistance to oxidation, but like other highly alloyed grades suffers from structural instability (precipitation of brittle phases such as sigma) at elevated temperatures. 904L should not be used above about 400°C.

Heat Treatment

Solution Treatment (Annealing) - heat to 1090-1175°C and cool rapidly. This grade cannot be hardened by thermal treatment.

Welding

904L can be successfully welded by all standard methods. Care needs to be taken as this grade solidifies fully austenitic, so is susceptible to hot cracking, particularly in constrained weldments. No pre-heat should be used and in most cases post weld heat treatment is also not required. AS 1554.6 pre-qualifies Grade 904L rods and electrodes for welding of 904L.

Applications

Typical applications include:

• Processing plant for sulphuric, phosphoric and acetic acids

• Pulp and paper processing

• Components in gas scrubbing plants

• Seawater cooling equipment

• Oil refinery components

• Wires in electrostatic precipitators

.jpg)

.jpg)

.jpg)