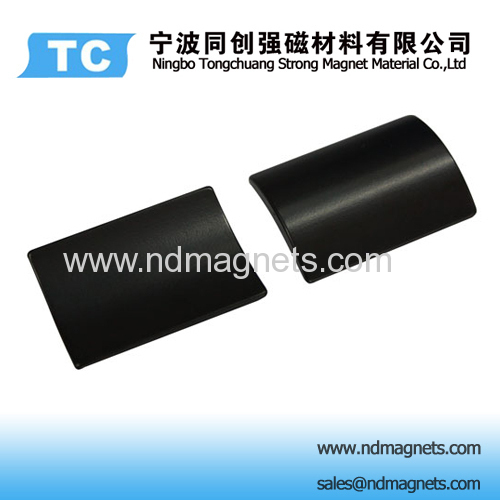

Product name:Arc magnets used in permanent magnet motors

Model No:ND-ARC010

Arc magnets used in permanent magnet motors

Property of this Magnet

Material:NdFeB magnet

Magnets grade :35SH,L-42SHT,42UH

Magnets size : Produced according to customer's design.

Magnetism direction :Pare magnetized

Magnets coating : Nickel,NICUNI

Max working Temperature: 180°C.-42UH

As an original magnet supplier, we can produce all the magnets according to customer's design. including magnet grade, magnet shape, coating etc.All our magnets are bespoke, due to that we are the original manufacturer. And there is no limit of minimum order quantity. Any trial orders are accebtable.

The magnet tolerance is very important for the motors. we use the go/No go gauge to guarantee the tolerance while mass production

go/No go gauge

| Magnetic properties of Sintered NdFeB magnets: | |||||

| Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Max. |

| Operating | |||||

| Temperature | |||||

| Br | Hcb | Hcj | ( BH ) | Tw | |

| max | |||||

| mT | kA/m | kA/m | kJ/m3 | ||

| (kGs) | (kOe) | (kOe) | (MGOe) | ||

| N35 | 1170-1220 | ≥ 868 | ≥ 955 | 263-287 | 80 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 12) | (33-36) | ||

| N38 | 1220-1250 | ≥ 899 | ≥ 955 | 287-310 | 80 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 12) | (36-39) | ||

| N40 | 1250-1280 | ≥ 907 | ≥ 955 | 302-326 | 80 °C |

| (12.5-12.8) | ( ≥ 11.4) | ( ≥ 12) | (38-41) | ||

| N42 | 1280-1320 | ≥ 915 | ≥ 955 | 318-342 | 80 °C |

| (12.8-13.2) | ( ≥ 11.5) | ( ≥ 12) | (40-43) | ||

| N45 | 1320-1380 | ≥ 923 | ≥ 955 | 342-366 | 80 °C |

| (13.2-13.8) | ( ≥ 11.6) | ( ≥ 12) | (43-46) | ||

| N48 | 1380-1420 | ≥ 923 | ≥ 876 | 366-390 | 80 °C |

| (13.8-14.2) | ( ≥ 11.6) | ( ≥ 12) | (46-49) | ||

| N50 | 1400-1450 | ≥ 796 | ≥ 876 | 382-406 | 80 °C |

| (14.0-14.5) | ( ≥ 10.0) | ( ≥ 11) | (48-51) | ||

| N52 | 1430-1480 | ≥ 796 | ≥ 876 | 398-422 | 60°C |

| (14.3-14.8) | ( ≥ 10.0) | ( ≥ 11) | (50-53) | ||

| 35M | 1170-1220 | ≥ 868 | ≥ 1114 | 263-287 | 100 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 14) | (33-36) | ||

| 38M | 1220-1250 | ≥ 899 | ≥ 1114 | 287-310 | 100 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 14) | (36-39) | ||

| 40M | 1250-1280 | ≥ 923 | ≥ 1114 | 302-326 | 100 °C |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 14) | (38-41) | ||

| 42M | 1280-1320 | ≥ 955 | ≥ 1114 | 318-342 | 100 °C |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 14) | (40-43) | ||

| 45M | 1320-1380 | ≥ 995 | ≥ 1114 | 342-366 | 100 °C |

| (13.2-13.8) | ( ≥ 12.5) | ( ≥ 14) | (43-46) | ||

| 48M | 1370-1430 | ≥ 1027 | ≥ 1114 | 366-390 | 100 °C |

| (13.7-14.3) | ( ≥ 12.9) | ( ≥ 14) | (46-49) | ||

| 50M | 1400-1450 | ≥ 1033 | ≥ 1114 | 382-406 | 100 °C |

| (14.0-14.5) | ( ≥ 13.0) | ( ≥ 14) | (48-51) | ||

| 35H | 1170-1220 | ≥ 868 | ≥ 1353 | 263-287 | 120 °C |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 17) | (33-36) | ||

| 38H | 1220-1250 | ≥ 899 | ≥ 1353 | 287-310 | 120 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 17) | (36-39) | ||

| 40H | 1250-1280 | ≥ 923 | ≥ 1353 | 302-326 | 120 °C |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 17) | (38-41) | ||

| 42H | 1280-1320 | ≥ 955 | ≥ 1353 | 318-342 | 120 °C |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 17) | (40-43) | ||

| 45H | 1320-1360 | ≥ 963 | ≥ 1353 | 342-366 | 120 °C |

| (13.2-13.6) | ( ≥ 12.1) | ( ≥ 17) | (43-46) | ||

| 48H | 1370-1430 | ≥ 955 | ≥ 1353 | 366-390 | 120 °C |

| (13.7-14.3) | ( ≥ 12.5) | ( ≥ 17) | (46-49) | ||

| 35SH | 1170-1220 | ≥ 876 | ≥ 1592 | 263-287 | 150 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 20) | (33-36) | ||

| 38SH | 1220-1250 | ≥ 907 | ≥ 1592 | 287-310 | 150 °C |

| (12.2-12.5) | ( ≥ 11.4) | ( ≥ 20) | (36-39) | ||

| 40SH | 1240-1280 | ≥ 939 | ≥ 1592 | 302-326 | 150 °C |

| (12.5-12.8) | ( ≥ 11.8) | ( ≥ 20) | (38-41) | ||

| 42SH | 1280-1320 | ≥ 987 | ≥ 1592 | 318-342 | 150 °C |

| (12.8-13.2) | ( ≥ 12.4) | ( ≥ 20) | (40-43) | ||

| 45SH | 1320-1380 | ≥ 1003 | ≥ 1592 | 342-366 | 150 °C |

| (13.2-13.8) | ( ≥ 12.6) | ( ≥ 20) | (43-46) | ||

| 28UH | 1040-1080 | ≥ 764 | ≥ 1990 | 207-231 | 180 °C |

| (10.4-10.8) | ( ≥ 9.6) | ( ≥ 25) | (26-29) | ||

| 30UH | 1080-1130 | ≥ 812 | ≥ 1990 | 223-247 | 180 °C |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 25) | (28-31) | ||

| 33UH | 1130-1170 | ≥ 852 | ≥ 1990 | 247-271 | 180 °C |

| (11.3-11.7) | ( ≥ 10.7) | ( ≥ 25) | (31-34) | ||

| 35UH | 1180-1220 | ≥ 860 | ≥ 1990 | 263-287 | 180 °C |

| (11.8-12.2) | ( ≥ 10.8) | ( ≥ 25) | (33-36) | ||

| 38UH | 1220-1250 | ≥ 876 | ≥ 1990 | 287-310 | 180 °C |

| (12.2-12.5) | ( ≥ 11.0) | ( ≥ 25) | (36-39) | ||

| 40UH | 1250-1280 | ≥ 899 | ≥ 1990 | 302-326 | 180 °C |

| (12.5-12.8) | ( ≥ 11.3) | ( ≥ 25) | (38-41) | ||

| 42UH | 1280-1320 | ≥ 899 | ≥ 1990 | 318-342 | 180 °C |

| (12.8-13.2) | ( ≥ 11.3) | ( ≥ 25) | (40-43) | ||

| 28EH | 1040-1080 | ≥ 780 | ≥ 2388 | 207-231 | 200 °C |

| (10.4-10.8) | ( ≥ 9.8) | ( ≥ 30) | (26-29) | ||

| 30EH | 1080-1130 | ≥ 812 | ≥ 2388 | 223-247 | 200 °C |

| (10.8-11.3) | ( ≥ 10.2) | ( ≥ 30) | (28-31) | ||

| 33EH | 1130-1170 | ≥ 876 | ≥ 2388 | 247-271 | 200 °C |

| (11.3-11.7) | ( ≥ 10.5) | ( ≥ 30) | (31-34) | ||

| 35EH | 1170-1220 | ≥ 876 | ≥ 2388 | 263-287 | 200 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 30) | (33-36) | ||

| 38EH | 1220-1250 | ≥ 899 | ≥ 2388 | 287-310 | 200 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 30) | (36-39) | ||

| 40EH | 1250-1280 | ≥ 899 | ≥ 2388 | 302-326 | 200 °C |

| (12.5-12.8) | ( ≥ 11.3) | ( ≥ 30) | (38-41) | ||

| 28AH | 1040-1080 | ≥ 787 | ≥ 2624 | 207-231 | 230 °C |

| (10.4-10.8) | ( ≥ 9.9) | ( ≥ 33) | (26-29) | ||

| 30AH | (1080-1130) | ≥ 819 | ≥ 2624 | 223-247 | 230 °C |

| (10.8-11.3) | ( ≥ 10.3) | ( ≥ 33) | (28-31) | ||

| 33AH | 1130-1170 | ≥ 843 | ≥ 2624 | 247-271 | 230 °C |

| (11.3-11.7) | ( ≥ 10.6) | ( ≥ 33) | (31-34) | ||

| 35AH | (1170-1220) | ≥ 876 | ≥ 2624 | 263-287 | 230 °C |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 33) | (33-36) | ||

| 38AH | 1220-1250 | ≥ 899 | ≥ 2624 | 287-310 | 230 °C |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 33) | (36-39) | ||

Our advantages: 1. Original factory with professional technical and service.

2. Strict quality control systems under certification TS16949 and ISO 9001

3. Latest facilities to support R&D, quality control, process control, final product inspection

4. Very low prices due to our production well controlled , process optimization,

5, Fast lead time

6. Motto: partnership with all customers

Some sizes of arc magnets

What information should I provide when ordering?

We will help you with your order. Usually we ask for the following information.

Material type and grade required.

Size and shape, if available, a sketch or drawing with dimensions and tolerances.

Max working temperature.

Delivered magnetized or unmagnetized? Magnetization direction?

Quantities required.

Coating required (if any)

Information on what you want to use the magnet for.

.jpg)