Brief introduction:

The SSV14 series modular lubrication grease and oil progressive divider valve is available for the lubrication equipment of operation pressure with 300bar, it is essential to check the trouble and clearing of fault.

It is easy to detect the fault if the distributor equipped with stroke indicator, remove piston locking screws, screw stroke indicator the indication pin pop-up that freely thus exports within the piston movement, there is no blockage, conversely , it can be identified failure the distributor existence.

Work principle: When the piston moves and moves to the right, indicating pin pushed out, once moved to the other side of the piston in the force of grease, indicating the pin and piston in the action of the spring back to its original position.

Work principle: When the piston moves and moves to the right, indicating pin pushed out, once moved to the other side of the piston in the force of grease, indicating the pin and piston in the action of the spring back to its original position.

If you do not install the indicator can be detected following:

1. Remove the main line, to determine whether the oil normally start the lubrication pump.

2. Screw on the main line, the three-way valve in the lubrication side, then the distributor oil outlet below the corresponding screw plug taken out one by one, and every time the pump is started, screw plug open, if the grease large spill, it indicates that the element is blocked, to remove the fault element and made a mark on it.

3. If no fault in the main distributor, then the secondary distributor according to the above method to be checked. It is recommended to install a butter mouth with a manual pump distributor detecting if the system is large.

1. Remove the main line, to determine whether the oil normally start the lubrication pump.

2. Screw on the main line, the three-way valve in the lubrication side, then the distributor oil outlet below the corresponding screw plug taken out one by one, and every time the pump is started, screw plug open, if the grease large spill, it indicates that the element is blocked, to remove the fault element and made a mark on it.

3. If no fault in the main distributor, then the secondary distributor according to the above method to be checked. It is recommended to install a butter mouth with a manual pump distributor detecting if the system is large.

Specification:

Model | Nominal pressure | Oil feeding flow | Starting pressure | Outlet port | Weight |

SSV-14 | 30Mpa | 0.2 ml/Cycle | ≤1.5Mpa | 14 | 3.0kgs |

Note: Using the medium for the cone is greater than 265 (25 ℃, 150g) 1/10mm, (NLGI0 # -2 #) of the grease. Such as the use of oil, viscosity grade than N68.

Code explanation:

SSV–14–K

SSV= SSV series of progressive divider valve

14= Numbers of outlets, 14 outlet ports

K= With indicator; Without indicator if omit

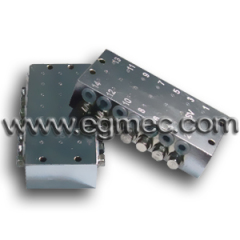

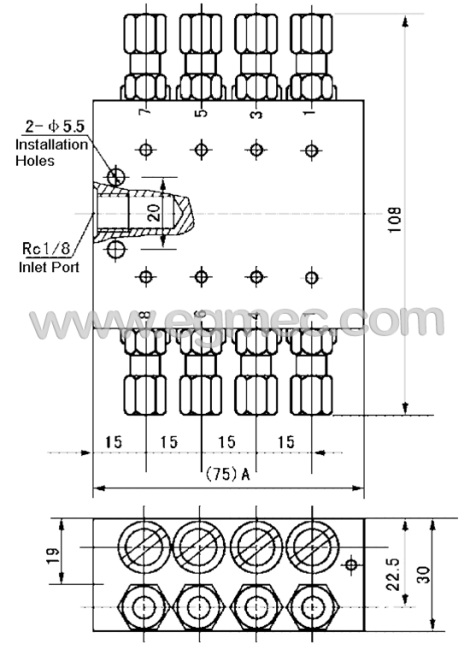

SSV14 series of modular lubrication grease and oil progressive divider valve dimensions:

Model | A | Max. Medium Flow Rate(ml/min) |

SSV-14 | 120 | 900 |

1.Outlet injectors : φ6 (Installed with the blocks)

2. Maximum pressure loss 10-20bar when grease through the working cell at 25 ℃ temperature.

2. Maximum pressure loss 10-20bar when grease through the working cell at 25 ℃ temperature.

Model SSV14 series of modular lubrication grease and oil progressive divider valvedescription:

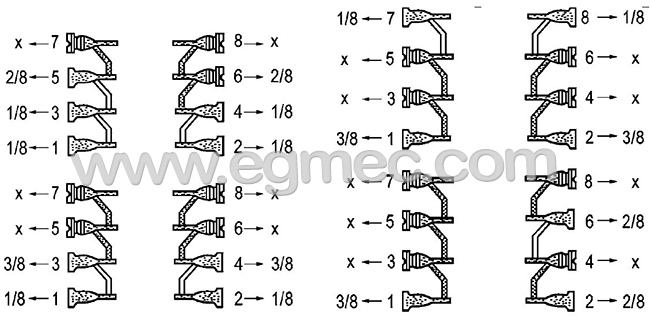

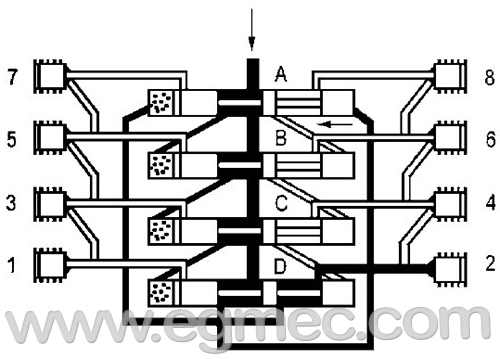

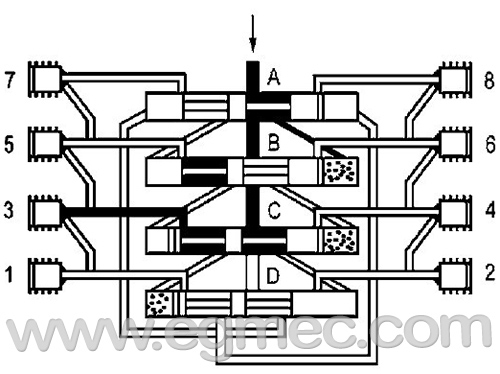

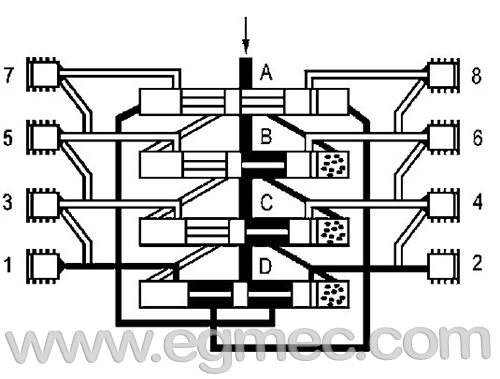

The grease/ oil enters into the distributor as per the direction of the arrow marked on the drawing above and transports to the end right of the piston A. The piston A moves to the left by the grease/oil pressure. The grease/oil in the position of piston A front left is transported to outlet 2 through internal passage of the house, reaches and lubricates the friction parts.

The right end passage connection of piston B is open while the piston A reaches the position of left end. The grease/oil flows into the right position of piston B and pushes the piston B moving to the left. The grease/oil store in left front of piston B is delivered to the outlet 7 through internal passage of the house.

The right end passage connection of piston C is open while the piston B reaches the position of left end. The grease/oil flows into the right position of piston C and pushes the piston C moving to the left. The grease/oil store in left front of piston C is delivered to the outlet 5 through internal passage of the house.

The right end passage connection of piston D is open while the piston D reaches the position of left end. The grease/oil flows into the right position of piston D and pushes the piston D moving to the left. The grease/oil store in left front of piston D is delivered to the outlet 3 through internal passage of the house.

The right end passage connection of piston D is open while the piston A reaches the position of left end. The grease/oil flows into the left position of piston A and pushes the piston A moving to the right. The grease/oil store in right of piston A is delivered to the outlet 1 through internal passage of the house.

When the piston B to D moves from the left to the right, according to the opposite direction above sequence of actions to complete a cycle and it will be restarting a new cycle

When the piston B to D moves from the left to the right, according to the opposite direction above sequence of actions to complete a cycle and it will be restarting a new cycle

How to use SSV14 series ofmodular lubrication grease and oil progressive divider valve:

1. Recommended maximum through two-level distribution of lubricants in the system. 2. Outlets ports 1 and 2 should be never closed.

3. Always use the original injectors and outlets connection pipes.

4. Dismantling exchange the nozzle parts from of each side of the upper or the lower outlets.

5. The nozzle must be removed if the outlets need to be blocked, merge the volume of grease (Changing to lower outlet port), the M10x1 is used to block the injectors as per the drawing below for example.