W24S-6,16,30,45,75,100 NC section bending machine(Angle roller)

I.Feature and function

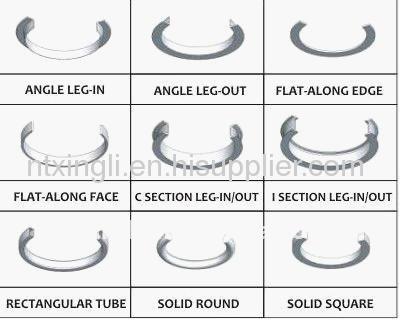

Section Bending machine is my company to introduce a new type of roll Italy technology to produce bending equipment, through the replacement of different mold, can roll bending angle, channel, I-steel, flat steel, square steel, round steel and various special-shaped steel, can be a complete material roll round, round the school process, widely used in petroleum, chemical, power, shipbuilding and machinery manufacturing industry.

The machine with three rollers are mainly the work of the drive roller, two side rollers can be used for arc lifting motion around the fixed center of rotation, the two sides of the working roll is provided with a roller device, to ensure the asymmetric profile rolling quality.The structure of the machine is advanced, reliable working, small volume, complete functions, is the profile shape equipment at home and abroad advanced.The machine configuration advanced general or special moulds, the machine has the advantages of convenient operation, high efficiency, welcomed by users.

FEATURES OF THE MACHINE

Motorized Drive of both Bottom Rolls.

Standard Roll Set.

Hardened Precision Threaded Shaft.

Adjustable Lateral Guides.

Emergency Stop.

Foot Pedal for Right and Left Rotation, Option of Reverse-Forward Starter.

Manual Adjustment of Upper Roll.

Hardened Rolls for Standard Profile.

Easy and Quick Roll Change.

Scale for Clear Adjustment of Top Roll.

All Shafts Run in Roller Bearings.

The Machine Frame is Welded Steel Construction.

Heavy Duty and Rigid Construction

Machine can be Operated by Semi-Skilled or Unskilled Operator.

These machines can bend wide range of structural steel section,Flat bars, Solid Square or Round, Angle Iron (Leg In or Out), Round Tube, Square Tube, Rectangular Tubing.

Technical parameters | W24S | ||||||||

6 | 16 | 30 | 45 | 75 | 100 | ||||

Flexural modulus of the largest cross-section profiles | 6 | 16 | 30 | 45 | 75 | 100 | |||

Coiling speed(m/min) | 6 | 5 | |||||||

Yielding Limit of Sheet Metal(Mpa) | 250 | ||||||||

Maximum cross section(mm) | 40×5 | 70×8 | 80×8 | 90×10 | 100×10 | 120×12 | |||

Minimum bending diameter(mm) | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | |||

Minimum cross section(mm) | 20×3 | 30×3 | 35×3 | 36×5 | 38×4 | 40×5 | |||

Minimum bending diameter(mm) | 400 | 550 | 560 | 600 | 600 | 720 | |||

Maximum cross section(mm) | 50×5 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | |||

Minimum bending diameter(mm) | 800 | 1000 | 1100 | 1300 | 1600 | 1800 | |||

Minimum cross section(mm) | 20×3 | 30×3 | 35×3 | 36×5 | 38×4 | 45×5 | |||

Minimum bending diameter(mm) | 400 | 550 | 500 | 600 | 700 | 760 | |||

Channel model | 8 | 12 | 16 | 20 | 25 | 28 | |||

Minimum bending diameter(mm) | 600 | 800 | 800 | 1000 | 1100 | 1700 | |||

Channel model | 8 | 12 | 16 | 20 | 25 | 28 | |||

Minimum bending diameter(mm) | 700 | 900 | 1000 | 1150 | 1600 | 1700 | |||

Maximum cross section(mm) | 100×18 | 150×25 | 180×25 | 200×30 | 220×40 | 250×40 | |||

Minimum bending diameter(mm) | 600 | 700 | 800 | 900 | 1000 | 1200 | |||

Maximum cross section(mm) | 50×12 | 75×16 | 90×20 | 100×25 | 110×40 | 120×40 | |||

Minimum bending diameter(mm) | 500 | 760 | 800 | 1000 | 1100 | 1300 | |||

Maximum cross section(mm) | 42×4 | 76×4.5 | 89×5 | 89×8 | 114×5 | 159×5 | |||

Minimum bending diameter(mm) | 500 | 750 | 900 | 900 | 1200 | 2000 | |||

Maximum cross section(mm) | 38 | 52 | 62 | 75 | 85 | 90 | |||

Minimum bending diameter(mm) | 450 | 600 | 600 | 800 | 1000 | 1100 | |||

Maximum cross section(mm) | 45×3 | 60×4 | 70×4 | 80×6 | 90×8 | 100×10 | |||

Minimum bending diameter(mm) | 750 | 900 | 1000 | 1200 | 1600 | 2000 | |||