We could send the sprayed well workpiece to the curing oven through the track.

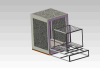

Electricity powder coating oven

Curing oven inner size is: 1000mm*1000mm*1500mm

Curing oven is U type, full-bridge structure, oven body is assembled construction.

The insulated panel: External δ 0.8mm cold-rolled board, internal: δ 0.8mm galvanized board.

Insulate layer: Thickness 120 with high quality rock wool

Heating system:

Insulation heating chamber: 100000kcal/h, quantity: 1set

Hot air circulation blower: Rotational speed: 2840r/min, power: 1.5KW

Stainless steel electric heating tube: 1KV*6PCS, total powder 6KW

Temperature: 0-200 centi-degree

We can also produce other different size of oven, please let us know if you have any other requirements.

| Power | Compressed air data | ||

| Pulse power | 15-20 colck/sec. | Max. Input are pressure | 10bar/145psi |

| Input voltage: | 110v-220v | Min inpur air pressure: | 6ar/87psi |

| Frequency: | 50-60Hz | Max water vapour content: | 1.3G/nm3 |

| Input power: | 50W | Powder hopper capacity: | 45L/55L |

| Putput voltage: | Max. 20v(peak-peak value) | Pneumatic control voltage: | 24VDC |

| Output current: | Mas. 0.8A | ||

1,powder paint coating oven of powder coating system

2,used for curing the workpiece which has been spraying during the powder

1,2,used for curing the workpiece which has been spraying during the powder coating.

Whena thermoset powder is exposed to elevated temperature, it begins tomelt, flows out, and then chemically reacts to form a higher molecularweight polymer in a network-like structure.

Structure:consist of Body,insulation, cover, heater. use gas to create the energy ,through the circulating fan ,make the temperature in the oven to rise uniformly. Then make the temperature of workpiece to rise.

built-in track to roll your powder coating racks into the ovens could be ordered together as you required.