Bimetallic injection molding machine screw barrel

Feature of bimetallic screw barrel of injection molding machine

1. Diameter of screw: D12-D300mm

2. L/D ratio of screw: 10 - 50

3. Injection amount of screw barrel: 45g - 200g

We have certificates of SGS and ISO9001:2008.

***Bimetallic screw barrel of injection Grade available:

1. Standard grade: 38CrMoAlA + nitriding 120 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

3. TC-A grade: Tungsten carbide 40%

4. TC-B grade: Tungsten carbide 15%

5. TC-C grade: Tungsten carbide 9.5%

***Material for bimetallic screw barrel of injection molding machine

The most popular material is 38Crmoala

Material for customer choose:

1)38CrMoALA(JIS SACM645)

2)42CrMo(JIS SCM440)

3)9Cr18MoV

4)CW6Mo5Cr4V2

5)Various high quality alloy steels,According to different usage, the choose for alloy is different, some require for abrasion-resistant while some require for corrsion-resistant. For standard, we have Fe-based, Ni-based, W2C alloy,Tunsten alloy etc for choice.

The foreign material we used as following:

*Germanysteel, GH113 ,2250 ,2842 ,1.8509 ,1.442 ,1.6582 ,1.6523 ,1.2080,1.4542,

*USA steel, P20,420,L6,H13,W110,D3,A2,D6,O1,S1,M35,8620,3115,K52440

*Sweden steel, 718S,718H,S136,S136H,STAVAX,ASP-23,ASP-30

*Australia Steel, M202,M300,W302,K460,W300,K900,K100,W321

*Hardnesssteel, YG6X,YG 6A,YG 6,YG8N,YG8,YG8C,YG11C,YG 15,YT5,YT14,YT30

*Japan Steel, SKT 4,YXM 4,YXM 42,SNC 815,SK -3,SKS 3,and etc.

***Treatment:

Heat-treatment

Nitriding treatment

Electroplate hard-chrome

High-frequency quenching

Spraying corrosion wear-resisting dual metal layers

Vacuum quenching

Technical Parameter |

| Steel Material | DIN 41CrA1Mo7 / AST M4140 / GB 38CrMoAlA /DC53/SKD61/HTP |

| Deepness of Nitriding Layer | 0.7 mm -0.9 mm |

| Hardness of Nitriding | HV900 - HV1,000 |

| Nitriding Brittleness | ≤Grade 1 |

Chromate plating | Thickness 0.05 mm - 0.10 mm, hardness HV950 |

Special treatment | Carbide coating on screw flight and bimetallic barrel |

| Screw straight tolerance | 0.015 mm/m |

| Surface roughness | Ra 0.4μm |

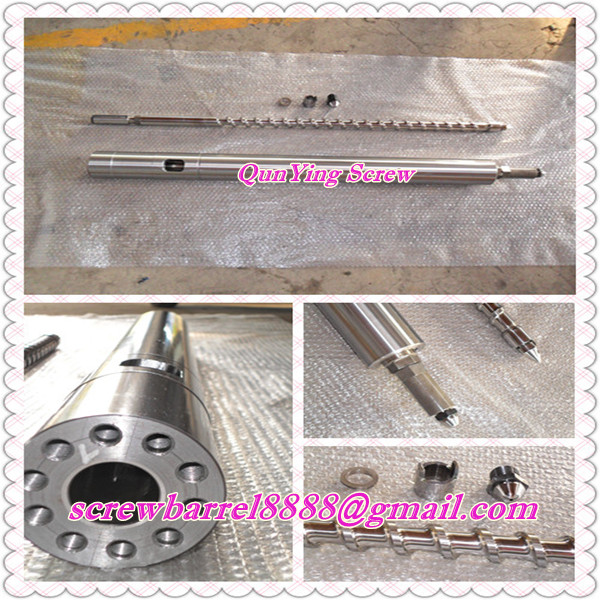

The photoes of our injection molding machine screw and barrel:

Instructions for our Screw&Barrel:

1.We are a professional company specialized in manufacturing many types of screw, the barrel can be applied on all types of injection moulding machine,rubber hot-feeding extruder, rubber cold-feeding extruder, pin barrel cold feed extruder, plastic extruder with different specifications.

2.The models of screw include:

Variable pitch and variable depth, variable pitch and equal depth, variable depth and equal pitch, and equal depth and pitch.

Groove multi-die type, composite type, mixing type and separating type.

3. The material of screw: manufactured with high-quality nitro alloy steel, applying the method of hardening and tempering and nitriding, thus it enjoys the characteristics of long working life, wear resistance, and anti corrosion. Besides, the technique of hard alloy spraying or chrome plating can be used on the working surface of screw, which will make it have better using effectiveness

CUSTOMER VISITING US:

Raw Material Show:

Product processing:

Bimetallic processing:

Certificate Show:

ISO9001:2008

SGS

We promise all our screw barrel are strictly quality controled as ISO 9001:2008 International Quality System&SGS System.

Like Former Prime Minister Wen Jiabao said in 2000,We should not only keep the quality with the word,but also to lead the world.

"QUNYING" Brand believe that Quality is the life, reputation is the cornerstone of development!

Choose QUNYING.

That's your best choice!