1, generally should be near the point of use and the temperature of the lowest, do not exceed the specified pressure and temperature.

2, before installation, please clean the pipeline installation, ensure the pipeline to ensure the normal operation of debris, filter.

3, should be installed vertically. The installation should leave the appropriate space below, to ensure normal operation of filter with the words. Compressed air filter before installation, please confirm the filter level, followed in accordance with low precision to high precision mounting.

4, no need to set up a bypass, because compressed gas filter does not need maintenance; but to keep in check drain drainage.

5, the installation should pay attention to the import and export orientation.

Note: 6, before using, in ensuring the connection level order, pipe sealing conditions are right, you can open the valve test run.

7, open the valve to open slowly, absolutely can not open instantly. Instantly turned on will cause instant impact of the filter, the filter core is damaged.

8, automatic drainer if drainage is poor, please clean the automatic drainage, drainage remove entire soaked in detergent solution, rinse with water after 10 minutes.

| TechnicalData | |||||

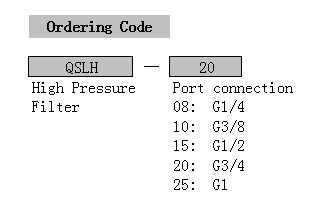

| Tybe | QSLH-08 | QSLH-10 | QSLH-15 | QSLH-20 | QSLH-25 |

| Operatingfluid | Air | ||||

| Joint pipebore | G1/4 | G3/8 | G1/2 | G3/4 | G1 |

| Filteringeliment roughness | 20um or40um | ||||

| Qorking ofadjustuble Pressure | 0.15~4.0MPa | ||||

| Max.inputpressure | 4MPa | ||||

| Operatingtemperature range | 5~80℃ | ||||

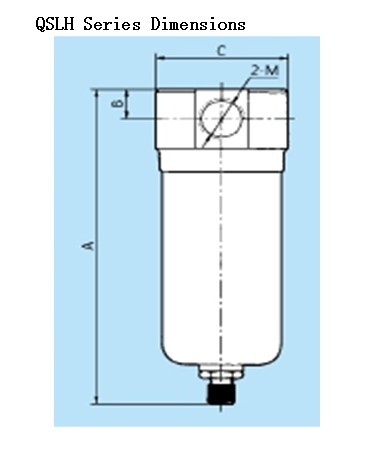

| Code | A | B | C | M |

| Bore | ||||

| 08 | 160 | 15 | 60 | G1/4 |

| 10 | 160 | 15 | 60 | G3/8 |

| 15 | 160 | 15 | 60 | G1/2 |

| 20 | 215 | 75 | 90 | G3/4 |

| 25 | 215 | 75 | 90 | G1 |

.jpg)

.gif)