plastic preform injection mould- 32 Cavities

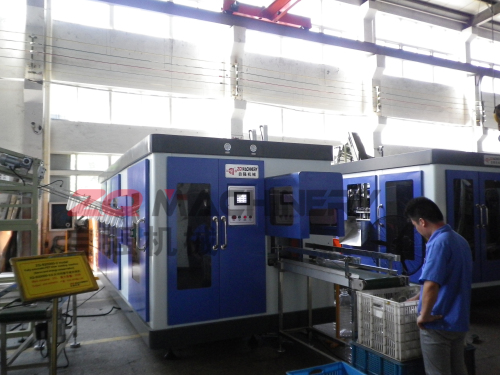

Usually, Multi-cavity pet preform moulddoes use the hot runner system rather than cold runner system, so thedesign of hot runner system plays an important role in mould qualityguarantee. Based on foreign advanced techniques and combined withdomestic clients' demand, we adopt the valve gated design, in which eachcavity has its own heating zone and temperature is measured byindependent thermocouple.(advantages: easily avoid some problems such aswhite or drawbench on bottom). Here, Mould is produced automatically toreduce labor force.

Main mould components (die core, diecavity, screw neck) are made by injection process, and the material ofwhich originates from Sweden high-quality mould steel (HRC 45).In thisway, it is no doubt that the mould can be used for 2 million shotswithout any maintenance, meanwhile, the wall thickness between max. partand min. part is not more than 0.10mm; turning center processes makesure that every parts can match well; proper distribution of coolingwater way improve productivity effect and molding cycle only takes 15seconds( need proper water chiller, bottle design and injectionmachine).

Our mould, designed and developed by ourengineers, is of high precision and long life span without traditionalproblems. In a word, Preform wall thickness is on error of 0.10mm;weight difference is less than 0.3g; 2-5 moulds per minute; 2 millionguarantee; utmost 144 cavities in one mould.

plastic preform injection mould - 32 Cavities

Main feature:

1.Mold cavity from 1 up to 144.

2.Electric control system with simulating stretch testing improve yield rate.

3.Adopt world advanced dipole taper localization technique, each cavity self-clamp independently, ensure mould concentricity.

4.The material of mould die core and die cavity are made of Sweden special mould steel.

5.International standard screw neck, imported nitrided steel with high hardness is of long usage.

6.Advanced hot runner design and even heating temperature make sure the high quality of plastic products.

7.Valve gated type without tail reduces labor force.

8.At least 2 million guarantee. - plastic preform injection mould

ZQ Machinery

.jpg)