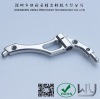

Deep Drawing Machining Metal Parts

We're forward thinkers,and that's evident in our equipment and facilities. We invest continuously inprocesses and systems designed to deliver greater product value tocustomers.

Process

Formingmetal on a bend press a main feature of sheet metal is its ability to be formedand shaped by a variety of processes. Each process does something different tothe metal giving it a different shape or size.

Stretching

Stretching is a process where sheet metal is clampedaround its edges and stretched over a die or form block. This process is mainlyused for the manufacture of aircraft wings, automotive door and windowpanels.

Drawing

Drawing forms sheet metal into cylindrical or box shapedparts by using a punch which presses the blank into a diecavity.

DeepDrawing

Deep Drawing is a type ofdrawing process where the depth of the part is greater than its diameter. Deepdrawing is used for making automotive fuel tanks, kitchen sinks, 2 piecesaluminum cans, etc.

Cutting

Cutting sheet metal can be done various ways from handtools called tin snips up to very large powered shears. With the advances intechnology, sheet metal cutting has turned to computers for precisecutting.

Bending andFlanging

Bending and flangingimparts stiffness to a sheet metal part or to form various shapes, such as 3piece aluminum cans.

Punching andShearing

During punching orshearing, the sheet metal is cut by using a punch and die.

Spinning

Spinning is used to make axis-symmetric parts byapplying a work piece to a rotating mandrel with the help of rollers or rigidtools. Spinning is used to make rocket motor casings and missile nose cones forexample.

PressForming

This is a form of bendingused for long and thin sheet metal parts.

Your friendly inquiry would be highly appreciated !

We believe that we can be your ideal partner !

.jpg)