Advandages of bimetallic

1. Corrosion resisting,

Some plastic materials such as Fluorine,PVC,ABS or add additive GF,etc,when temperature rise higher,will send out corrosive gas, which will damage your screw and barrel.Common nitrided screw barrel can not service long time,But bimetallic screw barrel is different,the bimetallic layer could resist the corrosion,make the screw barrel working life longer.We guarantee you the working life is one year,but our customers always use several years.

2.Wear resisting

Some times,we also need to add some materials easy to wear,such as Caco3,or recycled materials,these materials are called bad materials.Common nitrided screw barrel also could not serve you longer. Maybe half year, you need to change one set. In this situation,if you use our bimetallic screw barrel,we can guarantee one year. But our customers always use several years.

We-HUACHEN bimetalilc standard:

1. Standard grade: 38CrMoAlA + nitriding 96 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

3. HC-A grade: Tungsten carbide 40%

4. HC-B grade: Tungsten carbide 25%

5. HC-C grade: Tungsten carbide 15%

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

3. HC-A grade: Tungsten carbide 40%

4. HC-B grade: Tungsten carbide 25%

5. HC-C grade: Tungsten carbide 15%

We-HUACHEN Bimtallilc Product Show:

Two types of bimetallic screw:

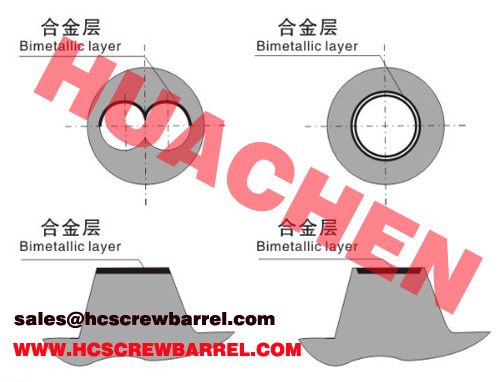

The bimetallic also could divide two types, like the above picture show:

Type 1:Sparying the bimetallic on the screw flight,this is very common in the market. If your plastic material is not very very bad,we suggest you choose this type, because of its economy.

Type 2:Coating the bimetallic on the whole screw,this is new technical these years. The advantage:Working life more longer than type 1,the disadvantage: Price is also very higher than type 1.

Barrel bimetallic:

Two types of bimetallic barrel:

About the bimetallic barrel,we also have two types:

Type 1,Groove bimetallic,we will make a groove on the barel first,then spary the bimetallic on the groove.

Type 2.Centrifuge casting.Bimetallic will attach to the inner wall of barrel equably.

We-HUACHEN Product Show:

Bimetallic screw

Bimetallic barrel

Walk into HUACHEN'S Workshop:

Bimetallic barrel processing (Centrifuge casting):

Bimetallic screw processing

Technical Parameter

Hardness after Hardening&tempering: | HB280-320 |

Nitrided Hardness: | HV900-1050 |

Nitrided Case Depth: | 0.5-0.8mm |

Nitrided Brittleness: | Less than Grade 2 |

Surface Roughness: | Ra 0.4 |

Screw Straightness: | 0.015mm |

Surface Chromium-plating's Hardness After Nitriding: | ≥900HV |

Chromium-plating Depth: | 0.025~0.10mm |

Alloy Hardness: | HRC56-65 |

Alloy Depth: | 0.8~2.0mm |

Bimetallic Thickness: | 2-5mm |

Bimetallic Hardness: | HV950-1100 |

Our specification

Advantage of our conical screw barrel:

Suitable for lens, transparent shell, cosmetics containers, transparent acrylic, nylon, PVC, PC, PPA, PPO,

PPS, PA6T, LCP, ABS, Bakelite, fire PC+ glass fiber, Nylon + glass fiber, powder, ceramic powder,

aluminum powder, iron powder and special engineering plastics.

About HUACHEN Design:

Walk into HUACHEN workshop:

1.Show you how to process the screws

2.Show you how to process barrels

About HUACHEN Design:

For good plasticizing effect,we have different designs of extruder twin screw barrel to meet customer's demand.

We have Gradual type, Mutant type, Wave type, Barrier type, Double barrier type, Shunt type, Separation type, Exhaust type, Pin type, Mixed type, Doubel-head type, Three-head type, Multi head.Walk into HUACHEN workshop:

1.Show you how to process the screws

2.Show you how to process barrels

3.Show you the nitrogenation oven where nitrided screw and barrels

(Yes,we own the nitrogenation oven, this is in our company)

4.Show you the heat-treatment.

(Yes,we also own this system, we could control our quality,not like small factory,who don't own heattreatmen and nitrogenation oven,can't control their quality)

5.Show you our IQC&FQC

We test our products from raw material to final product.

The picture is workman testing raw material

The picture is our workmen are testing the half-finished products.

(We test each processing step to make sure your good quality)

About HUACHEN

In the front of our factory--ZHEJIANG HUACHEN SCREW CO.,LTD

3.Show you the nitrogenation oven where nitrided screw and barrels

(Yes,we own the nitrogenation oven, this is in our company)

4.Show you the heat-treatment.

(Yes,we also own this system, we could control our quality,not like small factory,who don't own heattreatmen and nitrogenation oven,can't control their quality)

5.Show you our IQC&FQC

We test our products from raw material to final product.

The picture is workman testing raw material

The picture is our workmen are testing the half-finished products.

(We test each processing step to make sure your good quality)

About HUACHEN

In the front of our factory--ZHEJIANG HUACHEN SCREW CO.,LTD

3.Show you the nitrogenation oven where nitrided screw and barrels

(Yes,we own the nitrogenation oven, this is in our company)

4.Show you the heat-treatment.

(Yes,we also own this system, we could control our quality,not like small factory,who don't own heattreatmen and nitrogenation oven,can't control their quality)

5.Show you our IQC&FQC

We test our products from raw material to final product.

The picture is workman testing raw material

The picture is our workmen are testing the half-finished products.

(We test each processing step to make sure your good quality)

About HUACHEN

In the front of our factory--ZHEJIANG HUACHEN SCREW CO.,LTD

Established in the year 2001, we, "Zhejiang HUACHEN screw Co., Ltd " are engaged in manufacturing and supplying a diverse range of Screws & Barrels. These products are precision engineered using the best quality raw material that we procure from a trusted vendor base. Furthermore, the long lasting life, resistance against corrosion, dimensional accuracy, robust construction and economical prices of our range makes it suitable for heavy usage in most of the industrial applications.

Our dedicated team of professionals ensures that we produce only defect-free products so as cater to the long list of clientele. We possess great process knowledge for designing different set of products according to the specific requirements of our customers. Besides, our team members work in complete synchronization with the clients for meeting their varied industry needs and demands.

My skype: lillianyao0421

Choosing us is the best thing you have ever decided, and it's also our honour to be friends with u. Have a try.