Detailed Technical Information:

sheet 1

| Base Materials | 1)38CrMoAlA(JIS SACM645) 2)Cr12MOV(JIS SKD-11) 3)4Cr5MoSiV1(JIS SKD-61) 4)42CrMo(AISI 4140) |

| Bimetallic | 1)Fe-based alloy 2)Ni-based alloy 3)Co-based alloy 4)NiCo-based alloy 5)Tungsten carbide/Wolfram carbide |

| Tungsten Carbide | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containing tungsten of 9.5% |

Sheet 2

| Plstic material application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule),etc |

Sheet 3

Heat Treatment | High Frequency Treatment |

Nitriding treatment(120 Hours) | Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv (HRC56°-65°) |

Hard Chrome Plating treatment | Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV |

| Bimetallic treatment | Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° |

sheet 4

| Roughness of the surface | Ra0.4um |

| Linearity of the screw | ≤0.015mm |

| Linear axis limit | ≤0.02mm |

| Hardness after Hardening & Tempering | HB240-280 |

| Fragility of Nitration | ≤Two class |

Advantages of Parallel twin screws:

1.Good at feeding,especially for powder.And also have the superiority in bad heat-stability plastic materials and mixture palstic materials.

2.Compare to single screw barrel,It is better than single screw barrel in the followings: mixture materials,exhausting,self-cleaning.

3.Compare to conical twin screw, Parallel twin-screw and barrel is widely used in PVC products processing, especially for the production of PVC products with the output over 350Kg / h, because the parallel twin-screw and barrel costs less than conical twin-screw and barrel while it has more mature technology.

4.Application:Parallel twin-screw and barrel is successfully applied in PVC plate, pipe, profile, pellet and mould, at the same time, it solved the technical problem of low foaming, high foaming, high filling, wear and corrosion.

5.Other advantages:Good plasticization, high productivity, small shear force, stable pressure,less wear and tear and low cost.

4.Application:Parallel twin-screw and barrel is successfully applied in PVC plate, pipe, profile, pellet and mould, at the same time, it solved the technical problem of low foaming, high foaming, high filling, wear and corrosion.

5.Other advantages:Good plasticization, high productivity, small shear force, stable pressure,less wear and tear and low cost.

Sample Screw size:106*2965mm

Apply to: PVC pipe,(add some Caco3 powder)

We nitrided the screws first,then spary bimetallic on the screw flight.

Bimetallic screw,we dig a 2915mm hole in the screw to cool when the screws are working.

And like conical twin screws,we always will dig hole in the screw according to your customers requsests,then plug a cooper pipe into the hole. that could cool the screw when screws are on working.

Parallel twin screws (the middle section)

Handle of the Parallel twin screws

Machine processing parallel twin screws:

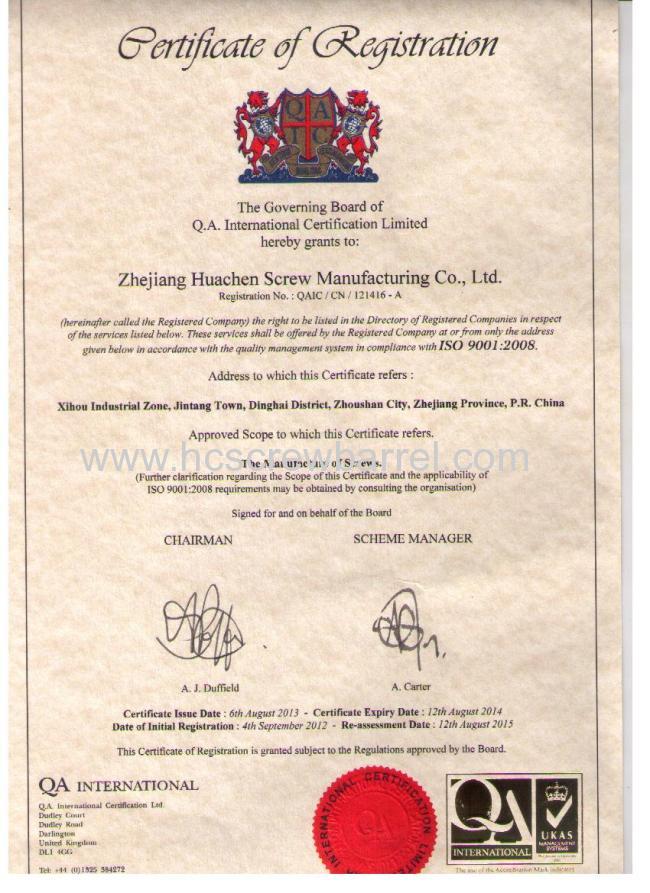

Our certificate of ISO 9001:2008 :

Quality Assurance

We strictly control our quality according to ISO 9001:2008

We strictly control our quality according to ISO 9001:2008

Quality is our main forte and we follow varied industry policies for achieving it. Furthermore, our quality consciousness has ensured that we manufacture premium quality Screw & Barrel for the clients. We conduct various quality tests on our range that start from the time of procuring raw material till the final supply of products. Apart from this, our quality controllers continuously check the entire range on different parameters so as to ensure its defect-free nature. Our quality testing laboratory is well-equipped with modern machines and technology that are necessary for bulk production.

Company photo

Welcome to inquire!

Welcome to inquire!We manufacture and supply a wide range of Screw Barrel product for our esteemed customers. These components are produced from high quality raw materials that result in unmatched durability and efficiency. To cater to the needs of our clients and their setup, we work in conjunction with them to design and fabricate the size of the Scroo-Barell. They are safe, cost-effective and match the high international standards of numerous industries

We can supply single screw barrel/cylinder parallel twin screw barrel conical twin screw barrel bimetallic screw barrel nitrided screw barrel injection moulding machine screw barrel extruder machine screw barrel rubber machine screw barrel.

My skype:lillianyao0421