We by the abundant technical force, perfect detection means, strict quality management, sophisticated processing equipment, has its place in the same industry. Our company strictly abide by equality and mutual benefit, quality first, customer supreme principle, is willing to provide warm and thoughtful pre-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

220t/h Fuel and Gas Boilers:

Fuel:blast furnace gas

Usage:industry or power station

Type:natural circulation

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Model No.:ZG Series Fuel:blast furnace gas Usage:industry or power station Pressure:high pressure Type:natural circulation Place of Origin:Henan,China (Mainland) Output:220t/h Structure:water tube Style:a vertical type with single drum

The avaliable fuel of ZG Series 220t/h Fuel and Gas Boiler is blast furnace gas. It has the advantages of high thermal efficiency,stable output.

\basic characteristics of ZG Series 220t/h Fuel and Gas Boiler

1.boiler specification

Index | Parameter |

rated evaporation capacity | 220t/h |

rated steam temperature | 540℃ |

rated steam pressure(gauge pressure) | 9.8MPa |

drum design working pressure (gauge pressure) | 11.3 MPa |

feed watertemperature | 215℃ |

exhaust gas temperature | 156℃ |

hot air temperature | 320℃ |

air preheater inlet air temperature | 25℃ |

boiler design efficiency | 86% |

2. boiler fuel

design fuel: blast furnace gas

ignition fuel: COG

dust content: ≤5mg/Nm3

fuel ingredient | content |

Co2 | 17.5% |

H2 | 1.8% |

N2 | 56.9% |

CO | 23.5% |

CH4 | 0.3% |

Qarnet | 781Kcal/Nm3 |

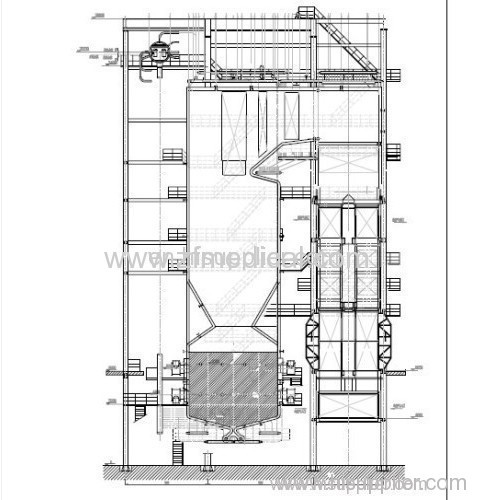

3. boiler basic dimensions

furnace width (both sides of the centerline distance between the waterwall) 7570mm

chamber depth (the distance between the front and rear water wall centerline) 7570mm

drum centerline elevation 35150mm

boiler highest elevation (connecting tube) 39350mm

boiler roof tube elevation 31890mm

operating Layer elevation 8000mm

architecture of boilers centerline distance between the left and right columns (outer column) 18000mm

boiler furnace frame column after column to the distance between the centerline 22000mm

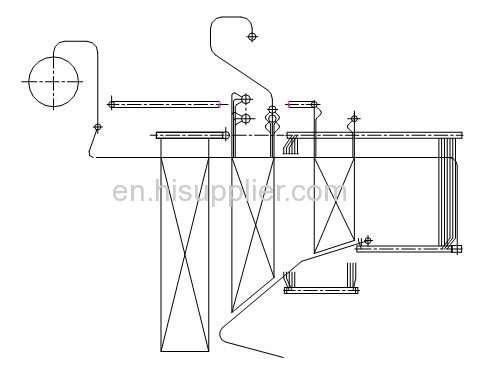

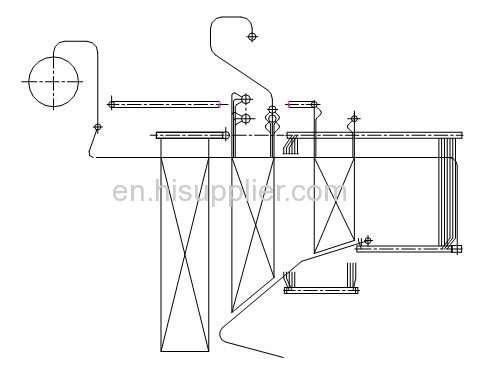

\ZG Series 220t/h Fuel and Gas Boiler structure outlined

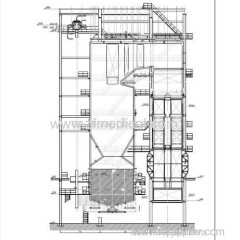

The type of ZG Series 220t/h Fuel and Gas Boiler is single drum, concentrated down tube, natural circulation Π-type arrangement of blast furnace gas furnace, semi-open layout. The front of the boiler is furnace, it arrang membrane wall. The outlet of the furnace is arranged platen superheater, horizontal flue install with two convection superheater. Roof, sides and horizontal flue pipe and the steering room set ceiling package wall tube. Furnance tail layout two economizer and air preheater.

ZG Series 220t/h Fuel and Gas Boiler adopts all-steel frame with double frame, It is suilt for 7 degree earthquake intensity, Ⅱ type venue fortification. Furnace water wall, superheater and economizer superiors are suspended in the roof beams, the lower economizer and air preheater supported on the rear of the column and the beam.

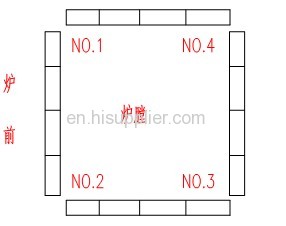

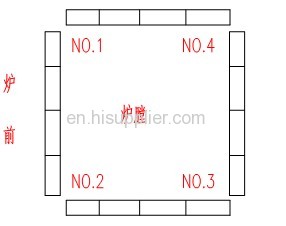

ZG Series 220t/h Fuel and Gas Boiler adopts swirl gas burner, front and back walls adopt two layout, it is total 12.

1.drum and separator device

Drum diameter isφ1600mm,it's thickness is 100mm.Head thickness is 100mm.Drum length is 13230mm,the material is P355GH(19Mn6). Drum normal water level is under the drum central 180mm,the highest water level and lowestwater level is 50mm far from the normal water level.Drum water level alarm value is ±125mm,Protective action value is +335mm,-250mm.

Drum adopts single-stage evaporation system,it layout cyclone,trapezoidal corrugated plate separator,washing plates and top perforated plate and other internal devices.The factions are seperating the water from soda mixture,cleaning the salt from steam,balancing drum steam load,so as to ensure steam quality.

Drum has 42 cyclone of diameterφ315mm.It is the frontandback rows,layout along the drum. Cyclone is packet assemble so as to ensure uniform load,obtain better separation. Soda mixture tangential entry into cyclone,it swirl flow in the barrel.As the faction of centrifugal force.

To the surrounding water drops left behind, to flow down along the tube wall, which steam flows upward in the cylinder, at the same time during ascent gravity separation, the separated water from the guide cylinder bottom steady flow into the water space. In order to prevent water from flowing walls rotated upward flow mixed with steam and, on top of the installation of a cyclone overflow tank, the water can flow through the overflow pipe outside the tank.

Drum adopts two sets of chain-piece drum hanger, which is suspended on the roof beams, lifting points are symmetrically arranged in the drum ends.

2.Furnace water wall

Furnace section is designed as a square, its depth and width is 7570mm.

The boiler water circulation, the concentration of each of the down tube supplying the four corners of the furnace tube's screen, so that the entire water wall can be divided into four circulation loop

.

Furnance

The boiler water circulation, the concentration of each of the down tube supplying the four corners of the furnace tube's screen, so that the entire water wall can be divided into four circulation loop

.

Furnance

3.bunner equipment

Boiler adopts swirl gas burner.

Burner is welded on the water wall by sealing the housing. When the downward expansion of the heated boiler water wall, the burner moves downward together with the water wall, the swelling capacity to compensate for the external pipes.

automatic ignition and fire hole is equipped at the burner center. fire detection and manual ignition hole is equipped nearby burner holes.When the burner nozzle outage , proper cold go through to protect the burner nozzle not be burned

4.superheater and steam temperature adjust

220t/h Fuel and Gas Boilers:

Fuel:blast furnace gas

Usage:industry or power station

Type:natural circulation