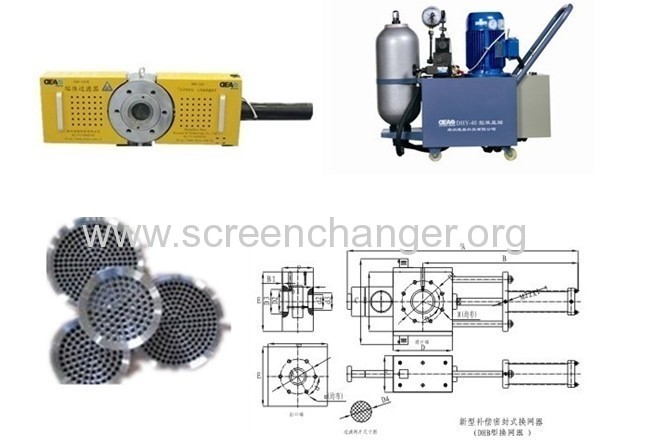

Hydraulic exchange screen for extrusion plastic machine-melt filter, single plate screen changer, discontinuous screen changer. hydraulic screen changer

Screen Diameter(mm) | Heating power(Kw) | Suitable Materials (Mpa) | Output(Kg/h) | |

DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

DHB-170 | Φ170 | 9.8 | ≤50 | 300-1000 |

DHB-200 | Φ200 | 11.6 | ≤50 | 400-1200 |

DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |

Our advantages

We are specialized in the research and manufacturing of melt filtration device/screen changer for more than 20 years. With strong scientific research team and mature technology; hold many international and national invention patents.

Our items can not only filter impurities, but also can greatly improve the plasticizing and homogenization effect of the raw material, make the product structure more homogeneous and product surface smoothness and quality much better, energy-saving and consumption-reducing, output- increasing and labor-saving

Single plate screen changer DHB series is quick

To move from the filtering screen in use to the clean screen takes only a minimum time, less than 2 times.

To move from the filtering screen in use to the clean screen takes only a minimum time, less than 2 times.

•Extraction and replacement of the filtering screens take place very quickly and maintenance can be carried out in a short time

•The speed of the change from one screen to the other means that the action of the extruder is not interrupted

Single plate screen changer DHB series is flexible

Single plate screen changer can be mounted both horizontally and vertically without affecting performance; in addition the single plate screen changer can be controlled by just one hydraulic unit.

Single plate screen changer DHB series is flexible

Single plate screen changer can be mounted both horizontally and vertically without affecting performance; in addition the single plate screen changer can be controlled by just one hydraulic unit.

•Mounted both horizontally and vertically, the single plate screen changer can be introduced very successfully onto pre-existing installations or where the space available is restricted, but without compromising high quality processing

•Several single plate screen changers can be controlled by the same hydraulic unit, resulting in large savings and maximum use of space

Single plate screen changer DHB series is safe

Single plate screen changer DHB series is safe

The screen changer is provided with several devices which guarantee its safe use.

•The safety blocking system of the doors and the hydraulic unit protects from the movements of the plates and from accidental opening during maintenance

•The block of the accumulator prevents the hydraulic unit to exceed the adjusted maximum pressure

• guarantee a perfect seal during the sliding of the plates

Special installations

The DHB SERIES can be installed both horizontally and vertically and can be introduced into pre-existing installations or where the space available is restricted but without compromising high quality processing.

For maximum use of space, and economic advantage, several DHB series screen changers can be connected to one hydraulic unit.

The applications

theDHB series a solution for granulation, re-granulation and regeneration installations as well as processing lines of blown films, bubble, films, casts, sheets, flat head plates, pipes, profiles, Hot Melt.